A special project team worked on reviving a Toyopet Racer, Toyota's first racing car from over 70 years ago. This story reports on the engine restoration work in full swing.

Following the first part, reporting on how the engine team’s challenge started, this article shares their struggles as work ramped up.

A master’s skills in repairing damage

Shuhei Suzuki, Jiei Nakahodo, and Megumi Ishikuro finished the first step of restoring an S-type engine under the guidance of Shinmei Industry’s legendary mechanic Minoru Ishikawa. After disassembling the engine, the trio finished checking the condition of all parts.

But as they proceeded with the next step, they faced several major issues.

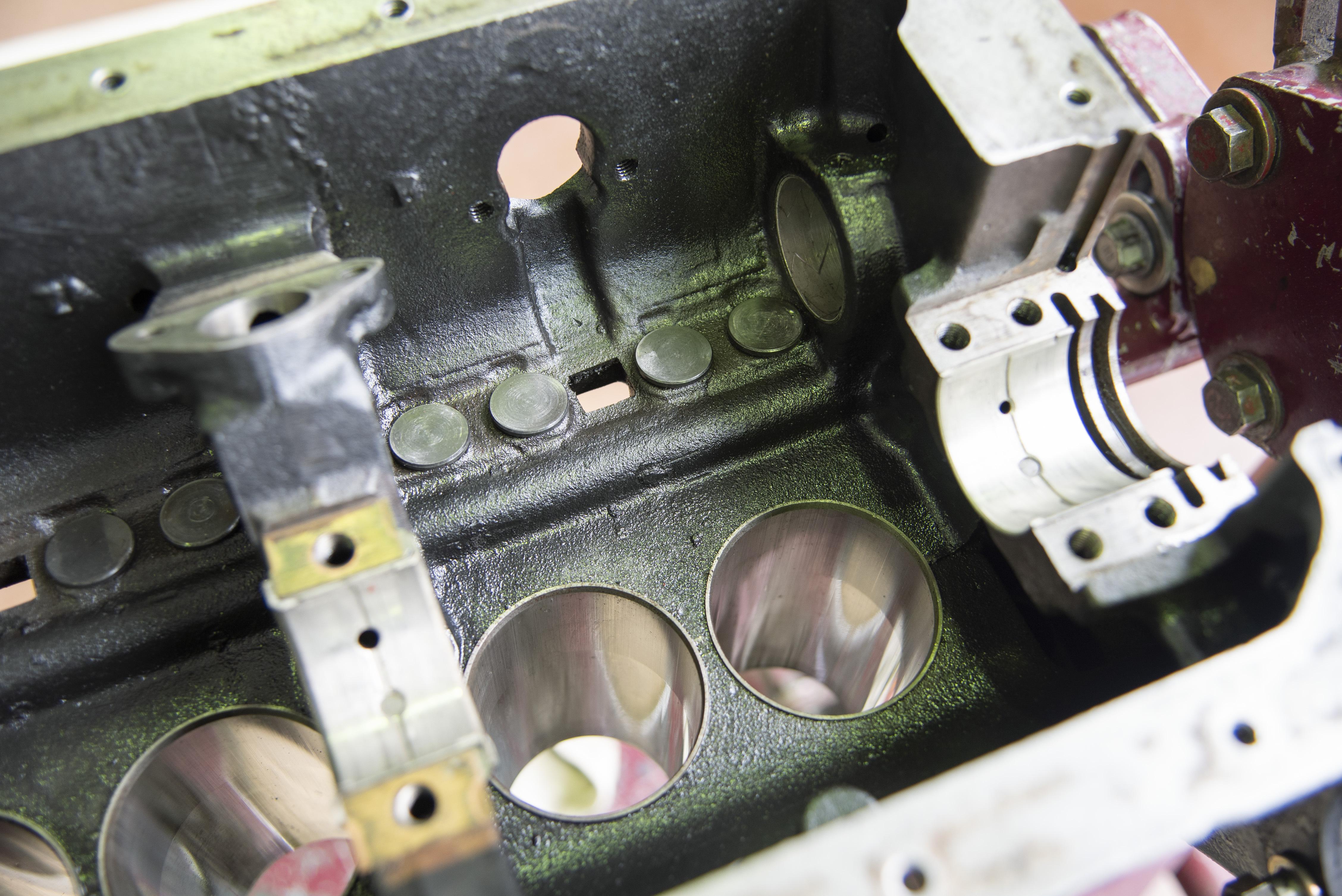

The first was scratches on the cylinder liners, which sit within the cylinder head and are in contact with the pistons. Another obstacle was a cracked metal part on the cap that attaches the connecting rod to the crankshaft.

Both are critical engine parts, and the defective conditions could cause the moving parts to seize and the entire engine to blow.

Nakahodo

When I saw the deep cracks in the connecting rod metal, I thought we might have to give up on the restoration.

Suzuki

Thankfully, Mr. Ishikawa and the Shinmei restoration team provided us with a lot of expertise in restoring historic cars.

The engine team’s restoration policy was to use original parts wherever possible; they wanted to reproduce the engine’s original state, including the noise and vibration. The engine team was able to restore the two damaged parts thanks to Shinmei Industry’s many years of expertise.

First, they removed the cylinder liner scratches by carefully shaving the surface. This approach was possible because the S-type engine’s iron cylinder block had extra thickness for greater strength, unlike modern engines which are made thinner to reduce weight.

The cracked connecting rod part was recovered by padding the metal before machining it back to the original shape. This process highlighted time-honored techniques passed down by companies like Shinmei.

Struggling with a tight schedule

While the S-type engine restoration looked set to clear technical hurdles, the team had another challenge—keeping the work on schedule.

Ishikuro

The work took longer than expected, so we were behind the initial schedule. We would gather in person once a week on Tuesdays, and I would mostly work from home on other days, but I had to come in more to catch up. My colleagues would talk to me and wish me luck with the Toyopet Racer restoration.

Delays were completely understandable. Even for Suzuki, who had experience as a Formula Student mechanic, the S-type engine was uncharted territory. In that competition, Suzuki worked on a modern double overhead camshaft (DOHC) motorcycle engine with high output and RPMs. The side-valve S-type engine, designed and produced 70 years ago, was completely different.

Suzuki

Although we planned the restoration process down to daily work schedules at the start of the project, there were materials, attachment methods, and arrangements for stopping oil leaks that we had never seen before, and we often had to revise our plans. Each time, we fretted about falling behind schedule.

As the team approached its first ignition test on July 20, 2021, they faced a critical issue with one of the engine’s key components: the head gasket, which prevents gas from escaping through the gap between the cylinder block and cylinder head during combustion.

Nakahodo

Since gaskets aren’t reusable, we couldn’t use the one fitted in the original engine. But without it, we can’t bring the engine back to life. We had no choice but to put down our tools and leave the engine with Shinmei Industry. The schedule was very tight, and we were always playing catch-up.

Moreover, original materials could not be used for safety and environmental reasons, requiring a complete redesign. This problem vexed Nakahodo, who oversaw the head gasket. His regular work was parts machining, so designing a part from scratch was a new experience.

But in this project, members didn’t hesitate to take on challenges outside their expertise. For Nakahodo, designing the head gasket was one such challenge.

With advice from Suzuki, whose background lies in engine design, Nakahodo deciphered the head gasket specifications from surviving original drawings. He worked with a gasket manufacturer to determine the shape and materials.

Despite the tight schedule, the supplier agreed to the manufacturing plan and produced the newly designed head gasket. Nakahodo made it in time to assemble the part in the engine.

The last struggle when firing up the engine

Nakahodo and Suzuki worked on fine-tuning the engine until the day before the ignition test. Despite these complications, the trio was able to fire up the restored “Suzuki” S-type engine as planned on July 20.

The ignition trial took place at a workshop for testing engines in development. Among the many engines under testing, facility staff set up the Suzuki-team assembled S-type on a corner bench.

This workshop is equipped with everything needed to safely test an engine, including a power supply for the starter motor, a special ventilation system that connects to the exhaust manifold to safely vent high-temperature exhaust gases, and firefighting gear to respond rapidly in the event of an engine fire. The staff here fully cooperated with the engine team despite their busy schedules.

The restored S-type appeared surprisingly small compared to the other modern engines tested on nearby benches. Other restoration project members also gathered around to watch Suzuki preparing the engine with Ishikuro’s help. They eagerly awaited the moment when that 70-year-old engine would roar powerfully back to life.

Following a thorough briefing from the testing area safety officer, it was time to finally fire up the engine. Unfortunately, however, ignition did not happen.

As the other members watched, Suzuki switched on the S-type’s starter motor, but for some reason, the engine did not start. Suzuki adjusted the carburetor to feed more fuel to the cylinders. Still, the engine would not stir.

Suzuki

In that moment, my mind went blank. The assembly work had been properly done, and none of the parts had any issues, so I was sure the engine would start without trouble.

With the other project team members looking on, Suzuki and Ishikuro rechecked the engine on the spot. Having dissembled, designed, and re-assembled the engine themselves, they knew the S-type better than anyone else. The root cause was quickly discovered, and an hour later the engine roared resoundingly back to life. Their restoration was a success as the 70-year-old combustion chambers began to draw in present-day workshop air. The testing area was filled with applause and cheers from other project team members.

Suzuki

I was panicking at first. I thought we were done if the engine wouldn’t start. But seeing the other project members looking on with kindness helped calm me down. Then I started thinking about why the engine wasn’t running. The cause was that we had flooded the carburetor float chamber with too much fuel. Since we assembled the engine with our own hands, we were able to quickly determine the issue and solve it. When the engine finally started, I had a strong sense that those who came before us 70 years earlier had fixed cars in the same way.

As the restoration team’s youngest member, Suzuki was set to step away from the project after the ignition test for three months of practical training on the production floor. For that reason, he had felt pressure to give his all before setting off. Ishikuro, on the other hand, had kept her cool.

Ishikuro

Even when the engine didn’t start at first, I knew we’d be okay. When it finally did start, I was very relieved that we had managed to get it done on schedule.

An invaluable experience

The engine team had reached a milestone in its work. Although several key tasks still lay ahead—including engine installation onto the chassis, the racer’s first run, and performance testing on a chassis dynamometer— the trio looked back on the restoration and shared their takeaways.

Suzuki

I felt so much pressure in serving as a leader over senior staff, and I was initially overly worried about how to ensure success. However, reaching the point of firing up the engine made me believe in myself—you really can make things happen with enough passion and conviction. I’m so grateful to my two colleagues and the other project members who entrusted me to lead.

Nakahodo

Through this project, I was able to learn a lot about other car components like brakes, steering, and transmission. I always thought that “people improve cars,” but this time, the car gave me an opportunity to improve my knowledge and skills. I could also make new connections both inside and outside the company through sourcing parts. It was a great benefit to me personally.

Ishikuro

Before this project, I had only worked within the digital field, but now I’ve been able to experience the entire process up to physical manufacturing. I learned a lot about a field completely difficult from my regular work. This was an absolutely rare and invaluable experience. Moreover, I’m sure the network I made with people from various departments will also be helpful for my work in the future.

For all three, receiving guidance from leading restoration legend Minoru Ishikawa was also a valuable experience.

Nakahodo

He corrected us clearly when we did something wrong. It’s hard to find people like him who guide you like a good father figure.

Ishikuro

Mr. Ishikawa’s teaching style is something you rarely find these days, which made this a really valuable experience.

Suzuki

For me, he was like a grandfather and a mentor. He taught me a lot, both professionally and privately. When the project is all finished, the three of us want to express our gratitude to him.

(Text: Yasuhito Shibuya)