A special project team worked on reviving a Toyopet Racer, Toyota's first racing car from over 70 years ago. This fourth installment highlights the efforts of the engine restoration team.

This series features Toyota’s project to revive a legendary racing car by reporting on the project members’ efforts as well as the history and meaning behind the vehicle.

This article focuses on the challenge faced by the engine restoration team.

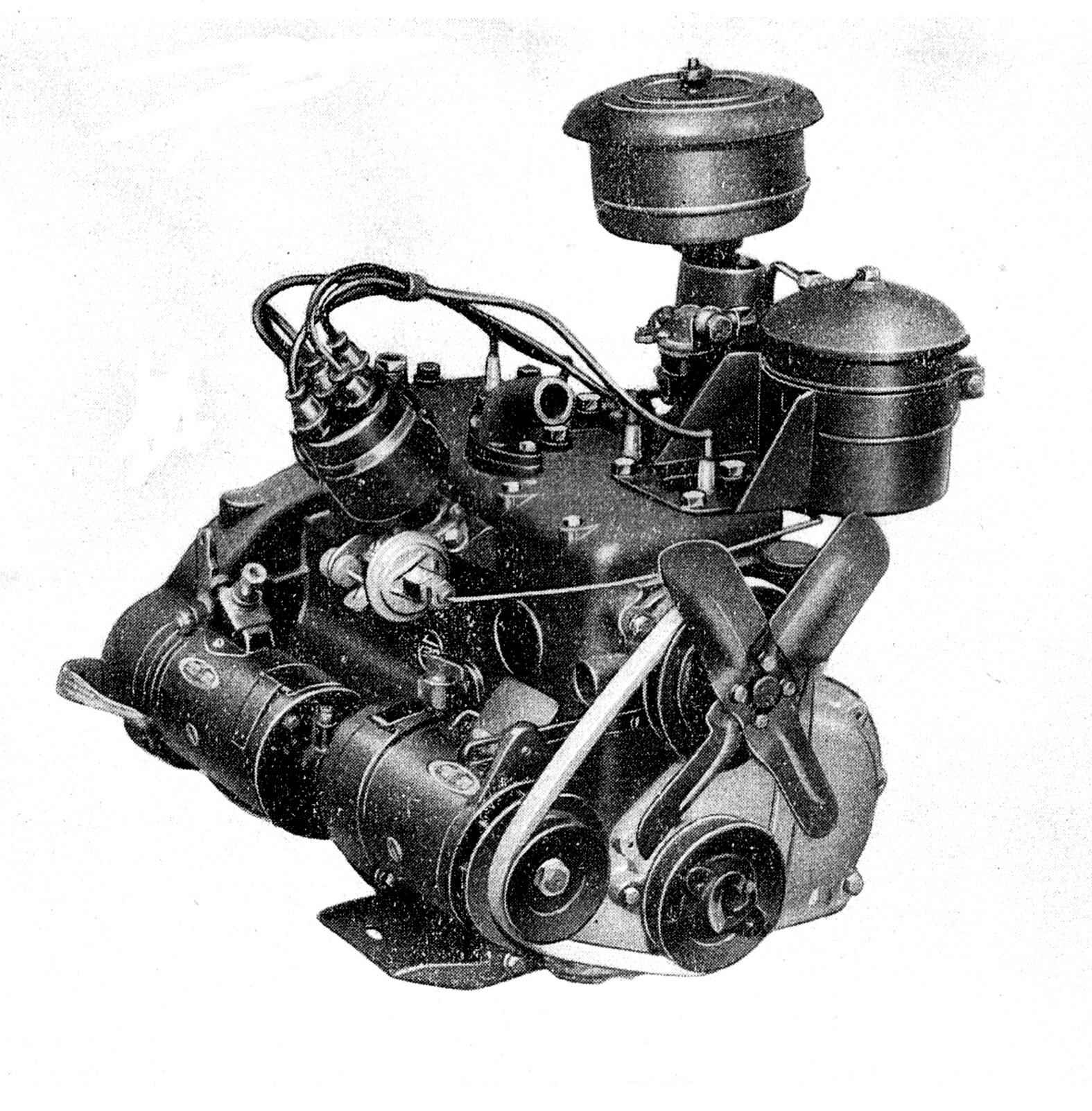

A preserved S-type engine

The Toyopet Racer is a cigar-shaped open-wheel racing car that Toyota developed over 70 years ago. Only two vehicles were produced in that first round, and they no longer exist now. The restoration team started by examining old photos and drawings to build individual vehicle components from scratch, including the chassis, suspension, and body.

Fortunately, the team found one authentic component they could refer to: the first generation Toyota S-type engine, now housed in the Toyota Automobile Museum. The Toyopet Racer used that engine, which started production in 1947. The museum also had a Toyopet Model SA passenger car, one of the legendary racing car’s roots.

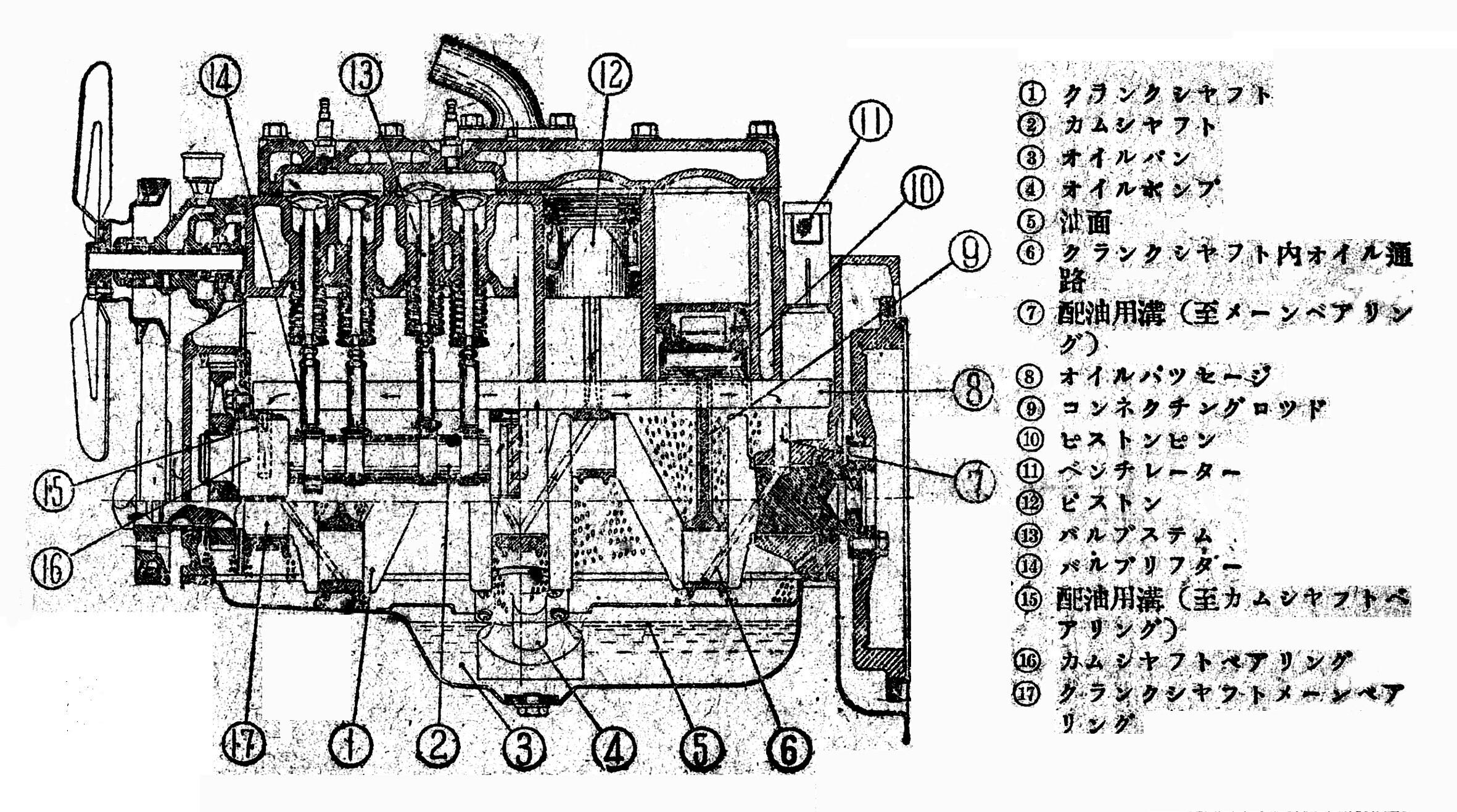

Toyota began designing the S-type engine in September 1945, just after the Second World War ended. This inline 4-cylinder 995cc engine, with a long stroke (bore/stroke: 65×75mm) and a compression ratio of 6.5, remained in production until August 1959. Toyota’s engines had previously used overhead valve configurations that enabled smaller combustion chambers with better power output and fuel efficiency. However, for the S-type, Toyota went with a simpler side-valve mechanism that was easy to produce and service, given the limited availability of materials and equipment. In fact, it is the first and last side-valve engine in the company’s history.

Three members were assigned to the engine team with the mission of restoring the S-type engine that had been sitting idle in the Toyota Automobile Museum.

A diverse trio teams up

Shuhei Suzuki, Jiei Nakahodo, and Megumi Ishikuro were assigned to the engine restoration team.

Shuhei Suzuki was in his first year at Toyota when this project started, making him the youngest of the three. He designs engine structures in the Powertrain Development Division No.1. At university, Suzuki participated as a mechanic in the Formula Student competition, run by the Society of Automotive Engineers of Japan, to cultivate the industry’s future talent.

Suzuki

I received an email from my division’s general manager telling me to make the most of my experience in the Formula Student competition. I was surprised because I had just joined Toyota, but he expected me to grow through this project. I had little confidence, but more than that, I thought I would crack under pressure. I almost burst into tears!

Jiei Nakahodo was in charge of the machining processes for building racing engine parts at the Production Engineering Division’s NC Data Section. An opportunity to take part in the restoration project was mainly offered to engineers in the development field, but Nakahodo, a technician on a manufacturing frontline, was passionate enough to apply. He was selected for his motivation towards the project.

Nakahodo

I wanted to work on an entire vehicle since my experience was limited to making individual parts like engine heads. That was why I applied for this project. But when I went to the first project team meeting, I noticed that I was the only technician. That made me 20% thrilled and 80% nervous.

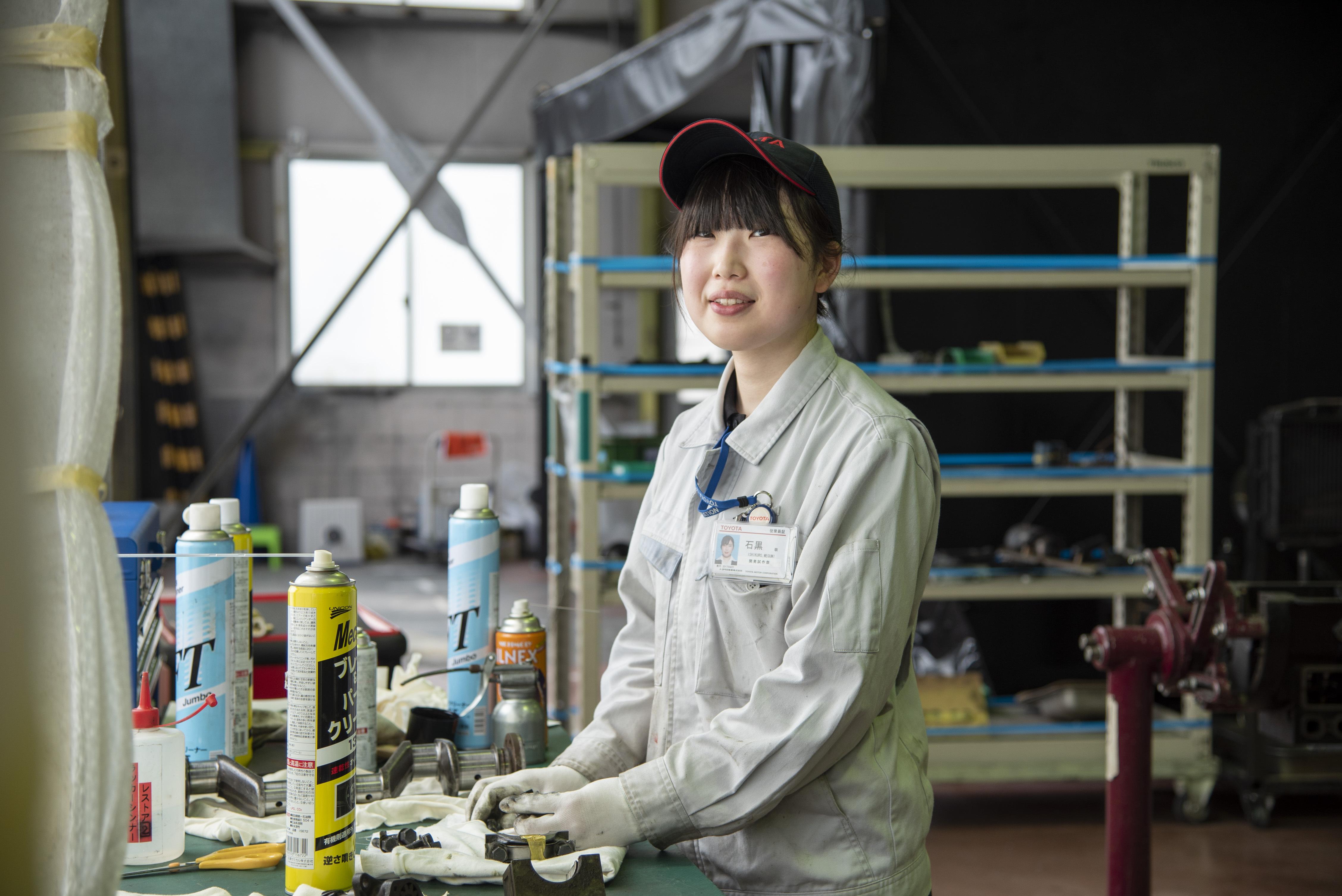

Megumi Ishikuro was part of the Prototype Division when the project kicked off. After researching semiconductors at university, she was assigned to the Information Systems Group. She was later moved to the Technical Development & Prototype Division, where she supports vehicle development through virtual reality and cross reality technologies to simulate packaging as well as interior and exterior designs.

Ishikuro

I heard about the project from my group manager. In my regular work, we treat the car as a space and focus on helping create enjoyable mobile spaces. I joined this project to support the team with digital technology, such as creating VR footage for displaying the restored Toyopet Racer at the museum. I haven’t had any training on the production floor before, so this was my very first time handling an engine. I never imagined myself in a workshop uniform and covered in grease.

This trio was placed in charge of the engine at the first project meeting on November 19, 2020, and so began their restoration work on the S-type engine from the Toyota Automobile Museum.

Suzuki was chosen to lead the engine team.

Suzuki

I was appointed engine team leader at the first meeting since there were no other members from an engine design division. It was a great honor, but the pressure was growing as the project moved ahead, partly because all the people around me were more experienced. I was told that the team was made up of younger members, so I expected there would be others who had joined Toyota the same year I did, but I was the only one.

The engine team’s goal was to achieve an output above 30 horsepower. This would put it above the 27 hp rating of the first S-type engine model, the Toyopet SA passenger car, and closer to the 33 hp of the last car powered by that engine, the first-generation Toyopet Corona. Figuring that anyone could make the engine simply run, the team set themselves the more ambitious restoration goal of improving on the original.

“Chasing 30 hp.” That was the goal that put the trio’s journey in motion.

Master Craftsman’s passionate guidance

The engine team had a reliable partner in Shinmei Industry, a Toyota partner company established in 1949.

Shinmei is involved in automobile maintenance, specialist vehicle production, new model prototype development, and making equipment and molds for car manufacturing plants. Their work also includes restoring historic cars at the Toyota Automobile Museum, just like the Toyopet Model SA.

Minoru Ishikawa, who led Shinmei’s restoration division and now serves as an advisor to the company, offered instruction for the team. Ishikawa is a legendary mechanic in the world of historic cars. The 83-year-old began working at the age of 15, giving him nearly seven decades of experience. Ishikawa was awarded a Medal with Yellow Ribbon by the Japanese government and is recognized as a Contemporary Master Craftsman in the field of automobile maintenance.

The restoration work began with disassembling the stored engine down to every single bolt and seal. Each part was checked thoroughly to determine its condition and figure out how to make it suitable for reuse.

Unlike Ishikawa, who experienced the S-type engine’s history in real-time, the three members were seeing it for the first time.

Suzuki

I had never disassembled a side-valve engine before. Compared to modern engines, there were far fewer parts, so the disassembly didn’t take much time. Despite some rust, the moving parts were in surprisingly good condition. I thought this would work.

Nakahodo

First of all, I had no idea what a side-valve engine was, so I didn’t understand the design of each part. In a regular engine, the cylinder head is quite thick because it houses the valves, but in a side-valve setup the head is very thin, which really surprised me.

Ishikuro

Even though I work for an automobile company, I had never experienced taking apart or assembling an engine, so I was impressed by seeing the structure of an engine and learned a lot.

Working with another discovered engine

Soon after disassembly work got underway, the team was blessed with a major windfall: they found another S-type engine. They could use the unit as a guide in restoring the disassembled engine.

Shinmei Industry had restored historic cars for Leaders II, a television drama that aired in March 2017 and was based on the life of Kiichiro Toyoda, Toyota Motor Corporation’s founder. Fortunately, Shinmei still had an S-type engine restored for the filming in storage. The members dubbed the engine “Leaders” after the drama, and the original one as “Suzuki” after the team leader.

Certain engine components had to be taken apart very carefully; if the disassembly went wrong, they could never be put back together. The trio carefully dismantled the engine under Ishikawa’s guidance. Once that was complete, the next step was to clean and polish any usable parts.

Suzuki

Mr. Ishikawa and other Shinmei staff taught us techniques for cleaning and polishing parts for reuse. Each part had lots of rust and dirt since the engine had been stored for a long time. Much of our time was spent cleaning and mending parts.

Despite the increased work with the introduction of a second engine, the trio worked together to disassemble, check, and clean components.

The next article introduces restoration work in action.

(Text: Yasuhito Shibuya)