This is part two of a report on the Takumi Kobo, which harnesses the sheet metal craftsmanship and monozukuri spirit passed down since Toyota's founding.

Here, we take a closer look at the team's aspirations and the monozukuri genba, the place where things are made.

Monozukuri genba fosters collaboration

What’s interesting—in a positive sense—is that each of the three craftspeople has a distinct style.

This is according to Akihiro Shiochi, who joined Toyota in 2014 after studying science and engineering at university. Since then, he has been involved in designing body press molds and using press technologies to develop new products. Shiochi has numerous challenging projects under his belt, which include realizing the complex designs of the GR86 and FJ Cruiser fuel lids.

Having joined the Takumi Kobo in April 2023, Shiochi is the team’s newest member. Despite that, his natural passion and dynamism, together with colleagues inside and outside the company, helped launch the Lexus fuel caps, which are another Kobo project.

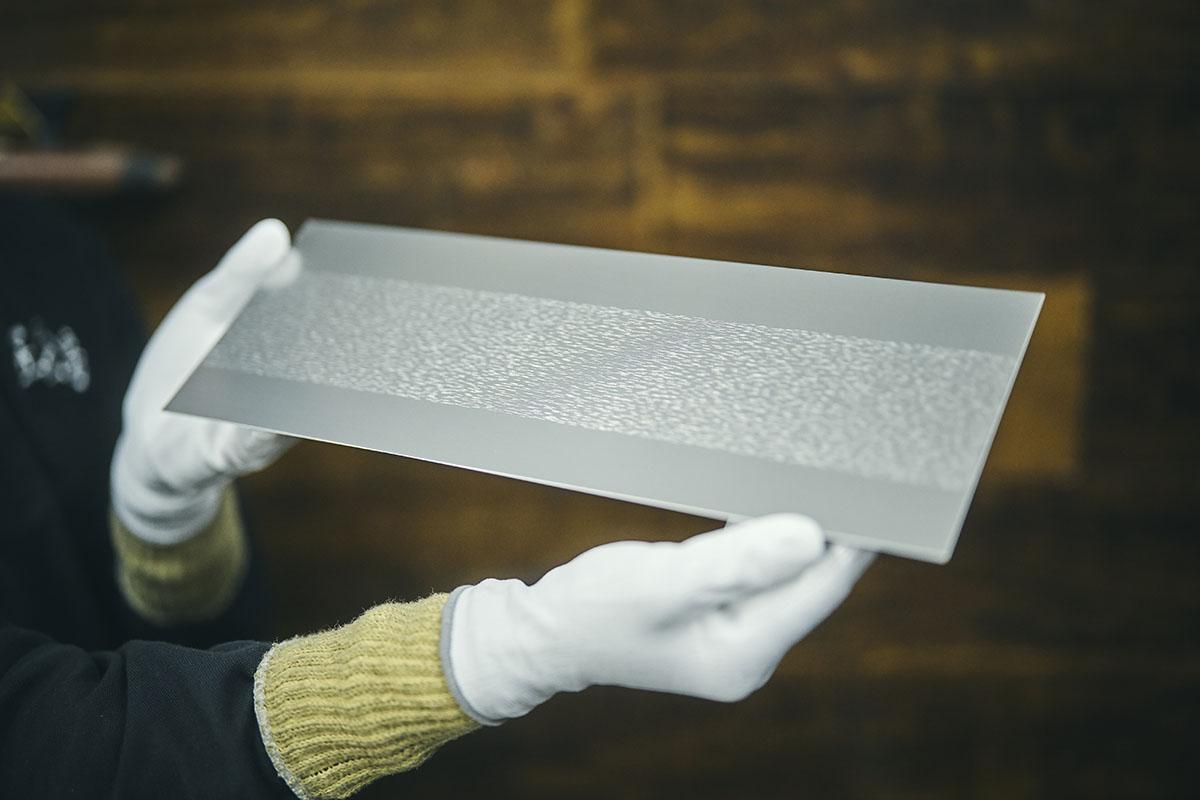

Shiochi also deals with Century scuff plates on a daily basis in the form of inspections. He makes the final checks for any flaws, ensuring that beautiful products can be delivered with confidence.

Shiochi

To my eye, Tsuchiya’s pieces have a playful side, while Horikawa’s work projects an orderly beauty. Meanwhile, Nitahara, while still in his late 20s, continues to push himself in different ways, and you can really sense him getting more sophisticated by the day.

The three takumi say they approach their work as though creating each piece for an individual customer, and true to their word, these plates have the feel of handicraft. Of course, their full value comes from being part of a car, so these products combine craft-like beauty with the precision of manufactured goods.

In this way, the scuff plates are a culmination of the ideas, skills, and exertions of all Takumi Kobo members.

While they don’t hear feedback directly from customers, their work has earned high praise from dealership specialist staff, known as Century Meisters.

Murata

Chief Engineer Tanaka also told us, “For the Century, it is important that we can offer customers these kinds of exclusive options.” Those words made me really happy.

Tanaka

Our ultimate ambition is to elevate the value of our monozukuri to the point where customers choose a car because it features products made with this craftsmanship or because our skills are embodied in the design.

And how about the Lexus fuel caps?

Horikawa

We trialled selling the fuel caps at a driving event for Lexus owners, and everyone who picked one up had a smile on their face.

Making people smile through the things we create—not only does this contribute to Toyota’s mission of “producing happiness for all,” but, as a craftsperson engaged in monozukuri, it also felt greatly rewarding.

All the Takumi Kobo members agree that what enabled them to push their skills to a new level was the existing relationships of mutual trust and encouragement—between supervisors and subordinates, senior and junior staff, technicians and craftspeople.

At the same time, they emphasize the essential role of various collaborators at Toyota and beyond, expressing no end of gratitude for these like-minded partners.

Skills exchanges with group companies and other manufacturers also bring many insights from peers who share the takumi mindset.

Gradually yet surely, these networks of co-creation fostered in the monozukuri genba are growing and will no doubt become a new force driving the future of Japanese manufacturing.