Engine sounds enchant car enthusiasts. In this article, we trace how Toyota began sculpting its unique sound.

The sound makes the brand

Later, engine sounds would become something that enhances product appeal. Around 1996-97, Toyota focused on creating a “brand sound.”

Since these efforts began in the division responsible for FF vehicles, development was aimed not at sports cars but medium-sized four-cylinder sedans.

European automakers served as the main benchmarks. In particular, Toyota looked to BMW, which deliberately emphasized its engine sounds and ensured that a distinctive brand tone could be heard in both its four- and six-cylinder vehicles.

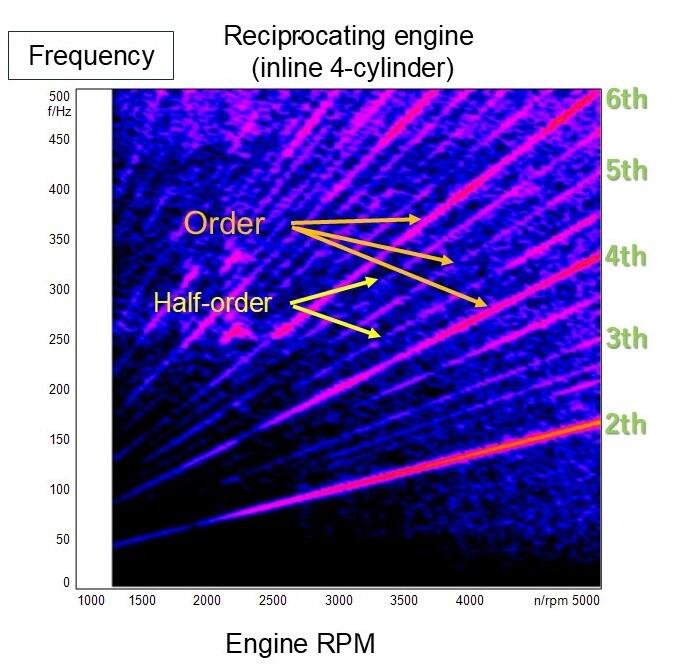

The development process began by using FFT maps* to analyze the engine sound characteristics of Japanese, American, and European carmakers. Toyota’s engineers also surveyed preferences in the three regions by having users listen to sounds they had created, examining how different cultural backgrounds shaped individual tastes.

*Fast Fourier Transform (FFT) maps are used to graphically analyze the distribution of vibration and noise frequencies at different engine speeds.

Here, we must refer back to the concept of order sounds, which we explained in the third article of this series.

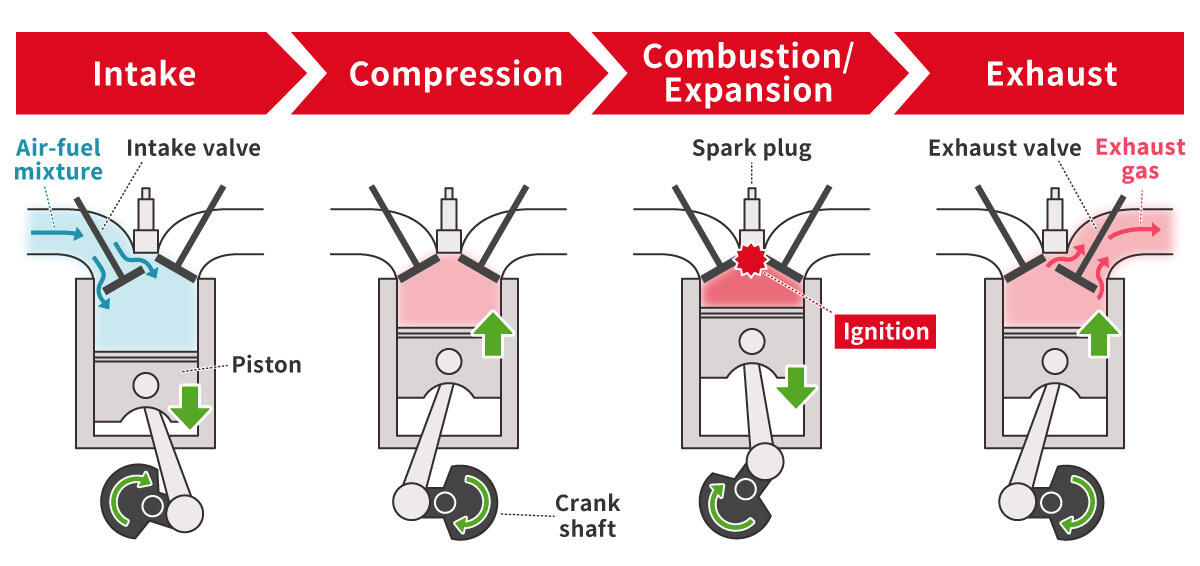

When plotting a distribution of the sounds emitted through the engine’s cycle of intake, compression, combustion/expansion, and exhaust, the straight lines rising left to right are known as order sounds.

In our first article, we discussed how combustion in a reciprocating engine occurs once per cylinder for every two revolutions of the crankshaft. The crankshaft’s rotation generates pulses (vibrations) that reach our ears as sound.

The graph above shows first-order sounds when one pulse occurs per revolution, and second-order when there are two. In an inline four-cylinder engine, combustion occurs twice for each revolution, which is why the even-numbered orders (2nd, 4th, etc.) appear strongest. The science here gets a bit complicated, but for our purpose, we can think of orders as the number of pulses per revolution.

Then what about half-order noise?

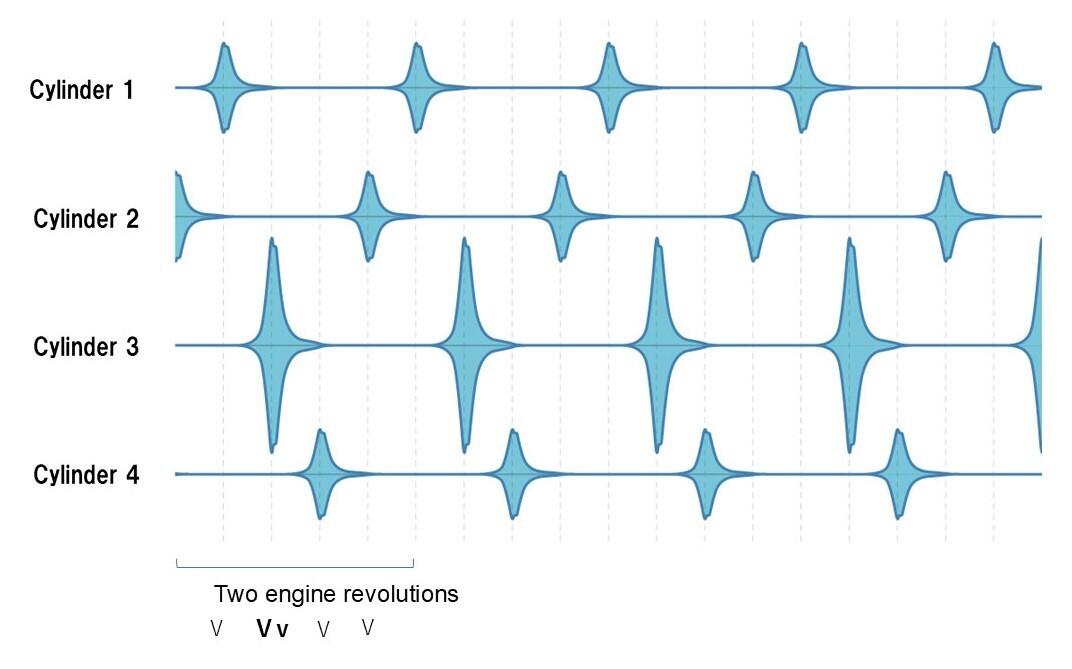

To make a car run smoothly, the combustion timings of cylinders are spaced out. The diagram below is an example of the pulse cycle for a four-cylinder engine.

In part two of the series, we explained how the boxer sound is created by manifolds of unequal lengths. Although the differences are not as extreme as in a boxer, inline engine cylinders also have piping lengths that vary according to the space available. As a result, each cylinder produces a different sound.

Think back to playing the recorder flute as a child, how the sound changed depending on the holes you covered and the distance between those holes and your mouth. Imagine a car’s intake and exhaust pipes as recorders, their lengths shaping the intake and exhaust sounds.

In the diagram above, the sound made by the third cylinder, which fires second, is louder than the others, and the difference between them emerges as a half-order.

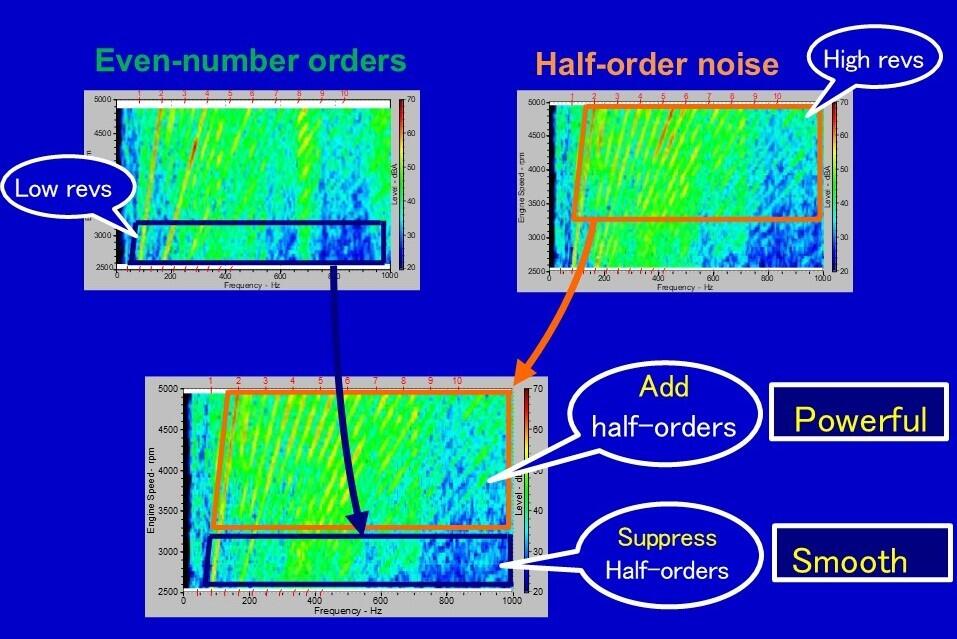

Analysis in Japan, the U.S., and Europe revealed that simpler engine tones consisting only of order sounds were pleasant at low RPM, but felt weak at higher. On the other hand, while half-order noise resulted in denser, more powerful sounds at high revs, at lower speeds many listeners felt that it made engines sound congested and sluggish.

To establish the sought-after brand sound, Toyota’s team also considered harmony—consonance and dissonance—to determine the ideal distribution of sound components for different engine speeds.

The pursuit of quietness had sought to add value by eliminating; now, there was a growing desire to go one step further, creating engine sounds that made products more appealing and strengthened the brand.

“By the time of developing the Lexus GS, you could certainly sense the desire to create a more intense sound,” says Sano. “This marked the first instance of sound development using sound generators, which was later adopted for the Toyota 86 and other models. Even so, at this point, we still hadn’t entirely gotten over the ‘quietness’ hurdle.”

The LFA breakthrough

So, when did Toyota clear that “quietness hurdle?”

“With the LFA,” says Sano, a response echoed by the other engineers we asked.

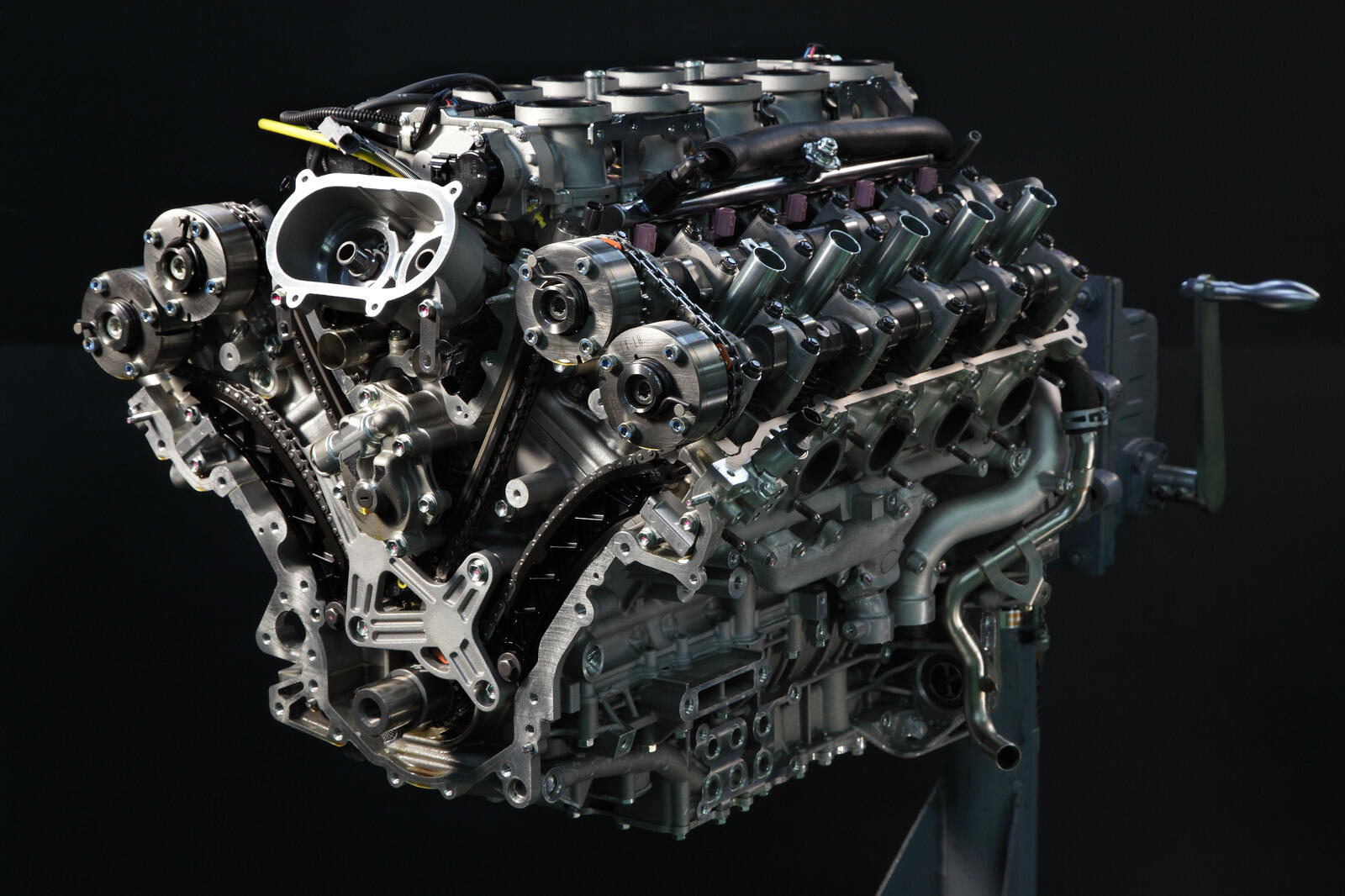

The LFA was launched in 2010, some ten years after planning first began, with just 500 units released worldwide. Equipped with a V10 engine that was more compact than a V8——thanks to each component being specially developed—the LFA became Lexus’s flagship sports car.

Assistant Manager Sano

The engineer overseeing sound design at the time stressed the need to deliver solid first-, second-, and third-order sounds. They worked to create an exhaust sound with clear octave harmonies, adding half-orders on the intake side at high RPMs to produce a dense, complex sound.

For the intake sound, they built and tested countless prototypes using original Yamaha’s technology.

They also incorporated analytical methods used in phonetics* to develop the ideal exhaust sound, powerful at low RPMs and with a sharper tone at higher revs.

*Phonetics: a scientific discipline that studies how sounds are created, transmitted, and perceived in human speech.

The LFA’s development involved a trial-and-error process of repeated prototyping and testing, adopting novel approaches from fields such as music and phonetics.

Sensitivity Performance Development Department Assistant Manager Yusuke Nakayama worked on sound production for the Lexus LC, which inherited the LFA’s sound factors as part of its DNA. “The LFA engine which produces that dramatic ‘roar of an angel’ sound is a V10 with perfectly even firing intervals,” he explains. “From what I’ve heard, the bank angle of 72 degrees was selected for the benefit of the sound.”

Nakayama’s comments are backed up by exhaust system documents from the time, which note that simulations that added two cylinders to a V8 engine with a 90-degree bank angle could not produce the ideal sound due to uneven firing intervals. Based on these results, the team wrote, “We’ve decided to develop an engine with a bank angle of 72 degrees.”

As touched on in our first article, V-type engines have two rows (or “banks”) of cylinders, and the angle of the V shape they create is known as the bank angle. This angle greatly affects the engine’s vibration, and, therefore, its sound.

In the LFA’s 72-degree bank angle V10, combustion within the cylinders occurs at equal intervals, producing less vibration and allowing the engine to run more smoothly. This makes for a purer sound.

Surely, then, shifting to 72 degrees could also improve the balance of other car engines, making them sound better? Unfortunately, the angle is also dictated by other factors, from engine bay space to the size and arrangement of individual engine components. The 72 degrees was only achieved by developing each part specifically for that purpose.

Toyota’s vision of creating the ideal engine sound culminated in the LFA.

Featuring: An equal-length exhaust system with an iconic three-pipe configuration, producing crystal-clear octave harmonies; an exhaust muffler that delivers a deep bass sound at low revs, and a true V10 roar at higher RPMs; an equal-length intake system that gives a distinct resonance to the rich intake sound; and a sound transfer mechanism that brings the intake sound inside the vehicle.

For the full experience of the LFA roar that marked a breakthrough in Lexus’s sound design, check out the video below.