This new series focuses on the engine sounds that enchant car fans. The first article gets down to the basics, explaining the relationship between engine mechanisms and sound.

Starting with the basics

To understand the sound of a car, which is generally defined by its engine, let’s begin with a brief run-through of how those engines work.

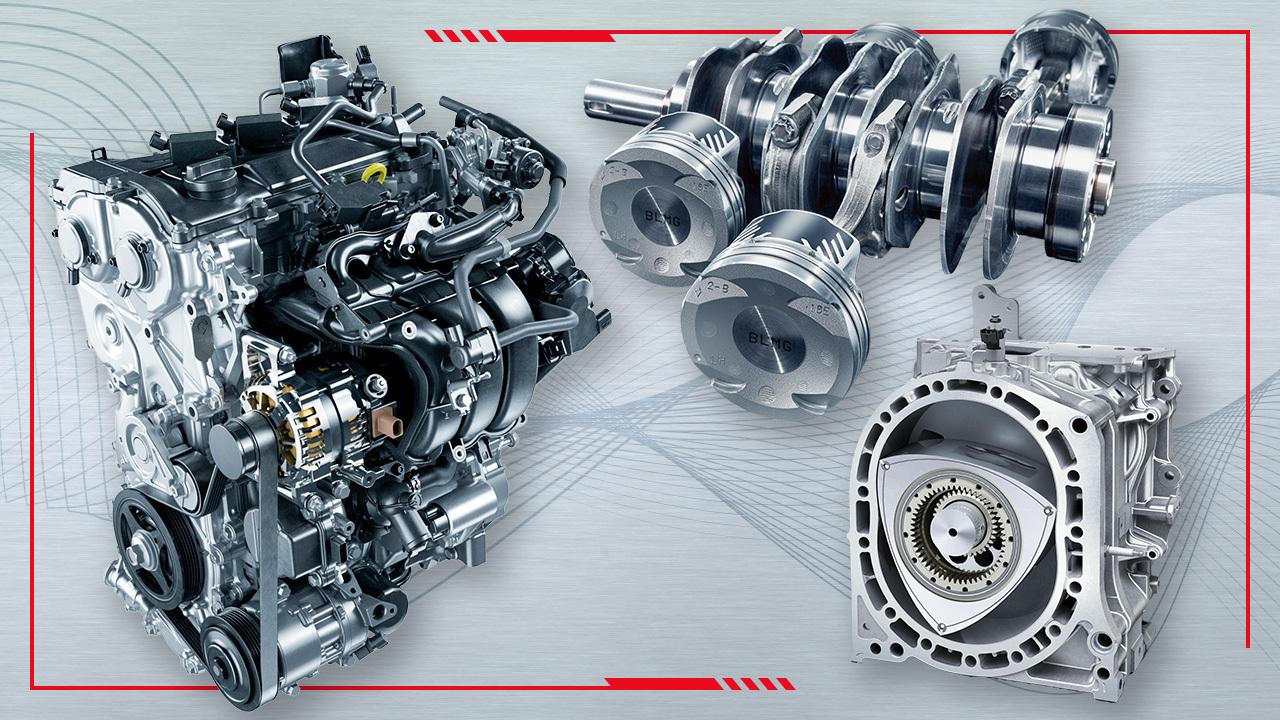

The most common type found in cars today is the reciprocating engine, which generates power by causing an air-gasoline mixture to combust (explode) inside the cylinders.

As the term “reciprocating” suggests, the pistons’ back-and-forth motion turns the crankshaft, and this rotation is transmitted to the tires to propel the car.

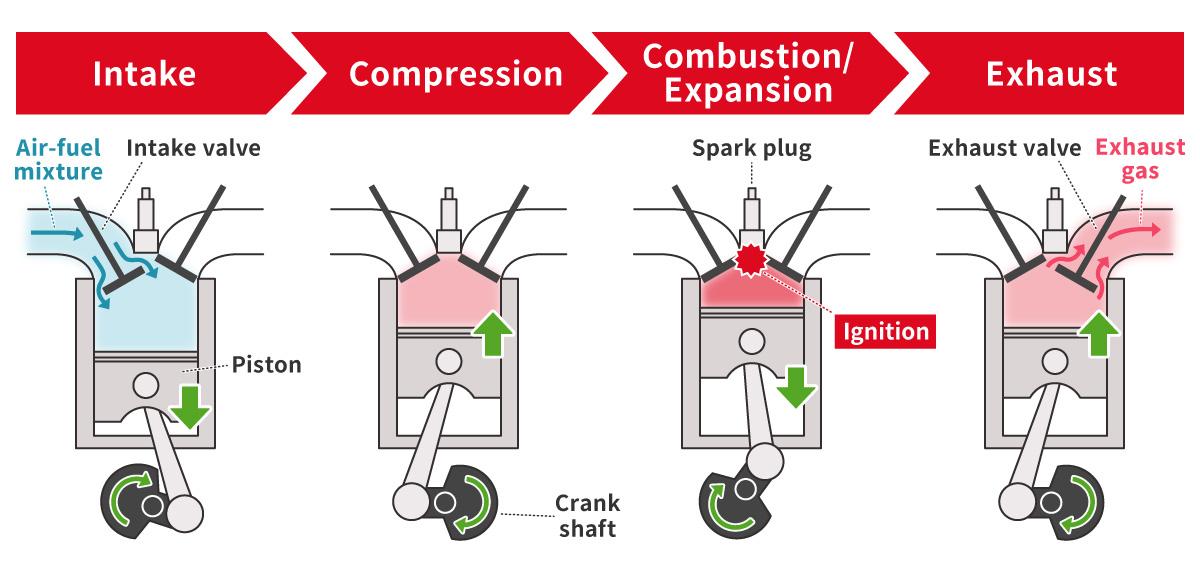

In a four-stroke engine, each piston completes four separate processes over two revolutions of the crankshaft: intake, compression, combustion/expansions, and exhaust.

No combustion without air

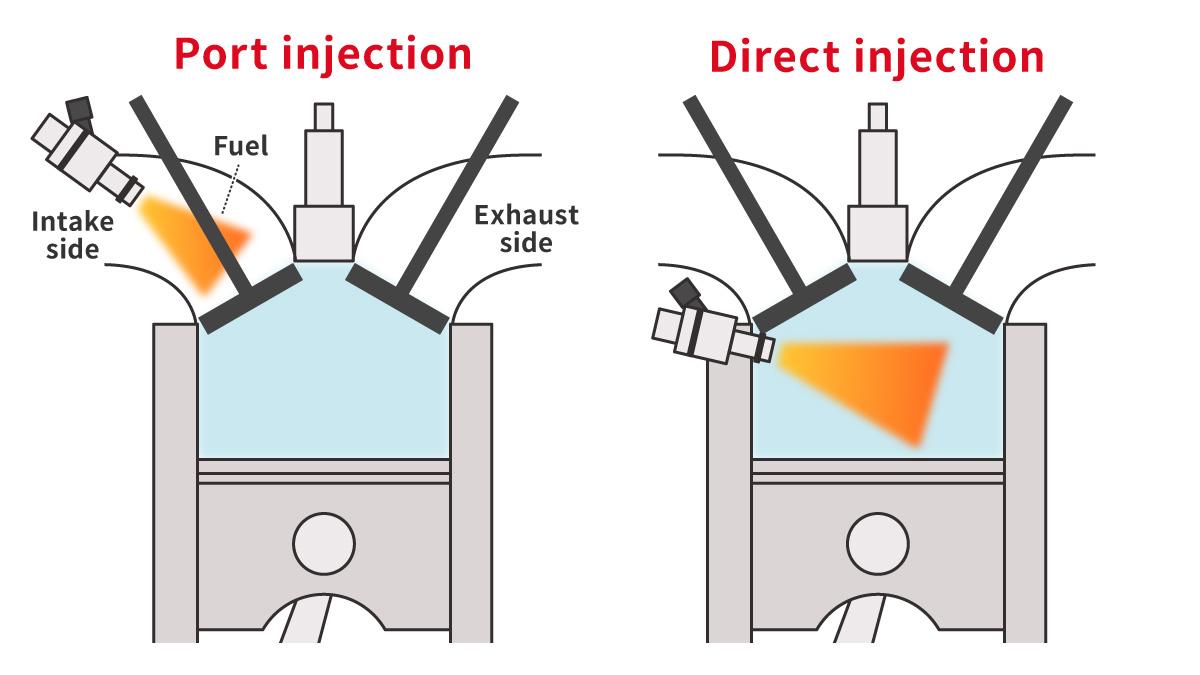

Fuel can be injected into cylinders either directly or through ports. The engines we have described so far use port injection, in which gasoline is sprayed into the intake manifold and sucked into the cylinder as an air-fuel mixture.

In a direct-injection engine, the intake manifold draws in only air, which mixes with fuel injected directly into the cylinder to enable combustion.

Regardless of the configuration, air is essential for burning fuel. An engine’s sound consists of not only this combustion and the engine’s mechanical vibrations, but also the noise of vast quantities of air being drawn in and expelled.

Essentially, the sound stems from vibration, airflow, and the air’s expansion or contraction.

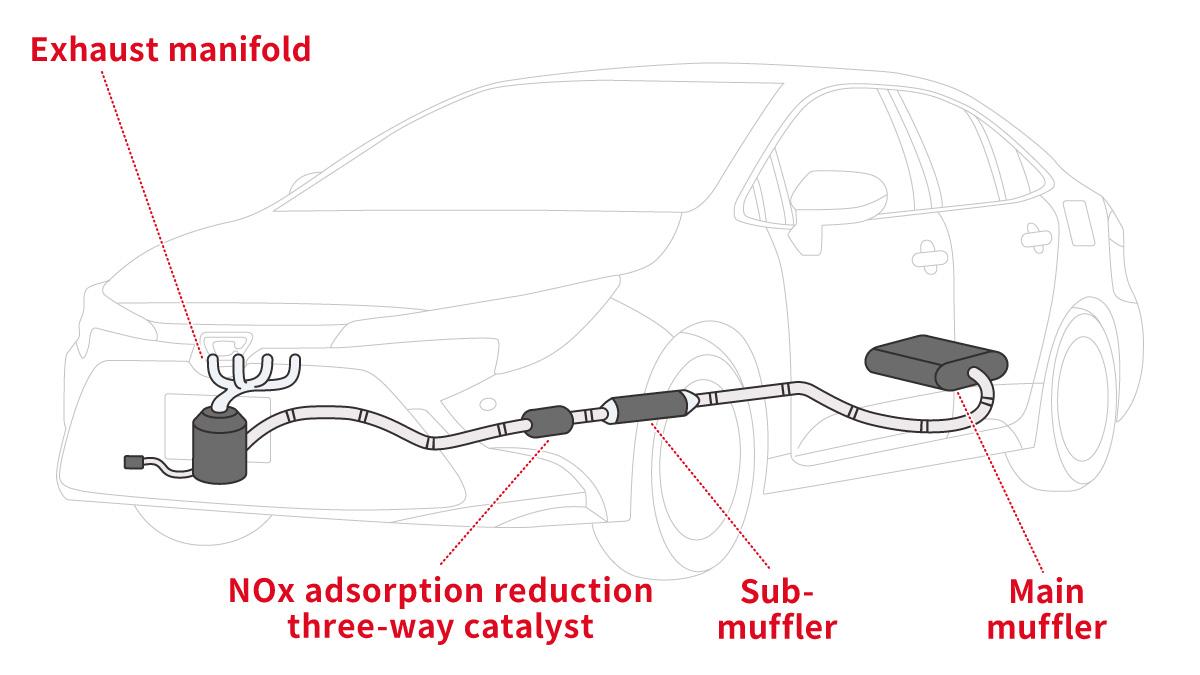

In particular, the exhaust manifold, through which gases are expelled after combustion, and the muffler have an outsized influence on the engine’s sound.

Generating more kinetic energy requires greater energy in the combustion process, and the key to this is more efficient delivery of air to the engine.

One way to do this is by increasing the displacement of each cylinder.

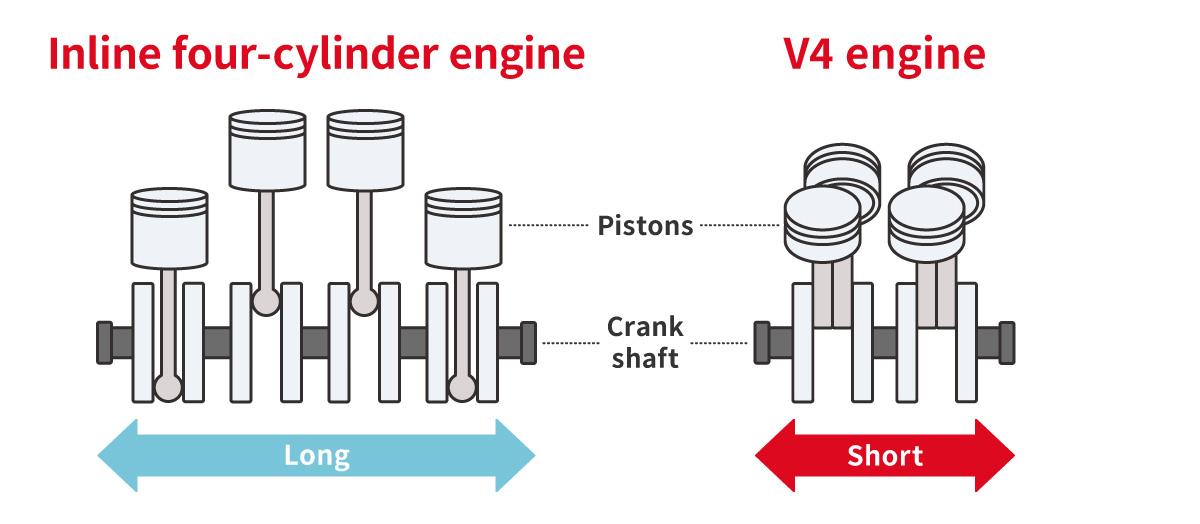

A second approach is to increase the number of cylinders. In an inline configuration, however, extra cylinders result in a longer engine that is harder to position in the engine bay. Instead, the cylinders can be arranged in a V shape.

Even so, adding parts inevitably raises cost, weight, and space requirements. In that sense, the best solution is always to make do with fewer cylinders.

That brings us to a third way of boosting energy: rapidly discharging the exhaust gases after combustion.

Various control techniques exist. One well-known and time-honored method involves adjusting the length and shape of the exhaust manifold—which collects and expels exhaust gases from the cylinders—to enable a smoother discharge with less interference.