Engine sounds enchant car enthusiasts. But how does the shape of an engine affect its tone? In the series' third article, we hear how rotary engines get their clean, high-pitched sound.

Mazda: an early endorser of Toyota Times

Toyota Times was launched in 2019 to give the world a glimpse inside Toyota. And yet, despite reporting on all things car-related, this newcomer had a hard time being recognized as part of the media landscape…

It was at this time that Mazda’s then-President Akira Marumoto invited Akio Toyoda (aka Morizo) to take part in the company’s historic Media Roadster 4 Hours Endurance Race—not as Toyota’s president, but as part of the media.

See our coverage of the event below:

Before the race, we found Morizo excited about his Roadster, saying, “I hope it has a rotary engine.”

Morizo is certainly not alone in falling under the rotary engine’s spell. Alongside its performance, the engine’s sound strikes a resonant chord with fans.

Following on from our last article, we are continuing to explore how an engine’s configuration affects its sound, this time delving deep into rotary engines.

The rotary engine

The rotary sound is clear and unconstrained. So how do rotary engines produce a tone that sets hearts racing?

Let’s start with a rundown of how they work. A rotary engine generates power by rotating a rounded-triangle shaped rotor—often likened to an “onigiri” rice ball in Japan--inside an oval housing, whose contours are known as a trochoidal curve.

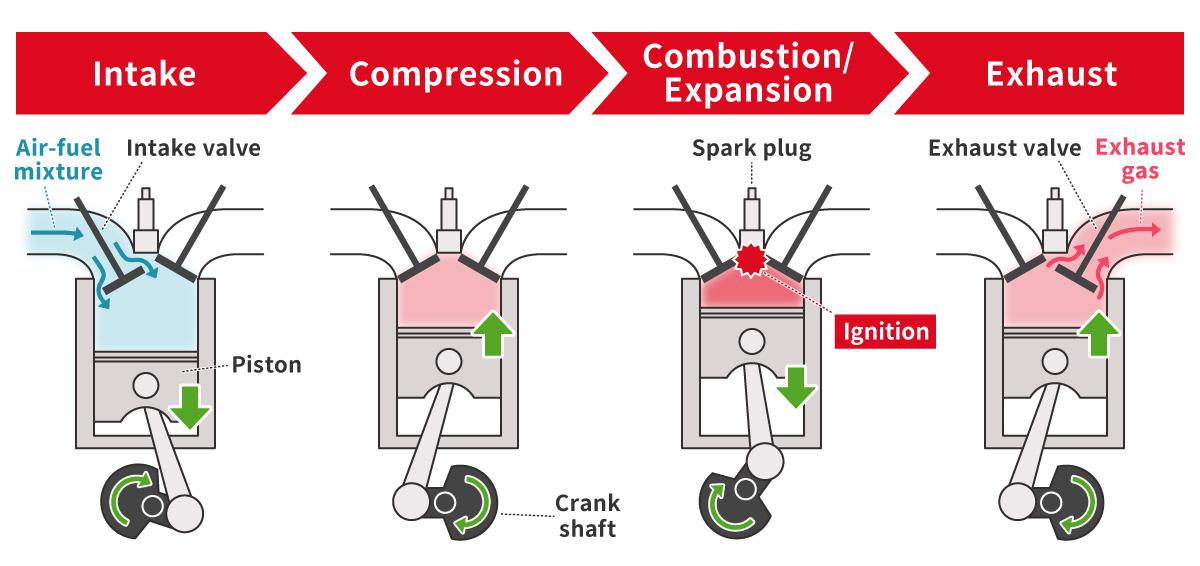

The apexes of the triangular rotor remain in contact with the housing’s inner wall, forming three separate chambers that cycle through the four processes—intake, compression, combustion/expansion, and exhaust—as the rotor spins.

This rotating motion turns the eccentric output shaft located at the rotor’s center, transmitting power to the wheels to make the car run.

What sound does a triangle make?

To learn about the relationship between rotary engines and sound, we visited Mazda to speak with Kiyoaki Iwata, Staff Manager at Engine Performance Development Gr. No.1, within the company’s Powertrain Development Division. In his time at the carmaker, he has been involved in noise vibration (NV) development across many types of engines, from diesel to gasoline, including rotary engines.

Iwata

A rotary engine doesn’t have the pistons found in regular engines, nor the system of valves that open and close for air intake and exhaust. This means it has very few parts and a simpler structure. Fewer parts result in less vibration, which is a cause of unwanted noise. This is one feature of rotary engines.

Secondly, the combustion intervals differ from those of reciprocating engines, including standard gasoline engines. (See Part 1 for an explanation of reciprocating engines)

In reciprocating engines, you get one combustion (explosion) for every two revolutions of the crankshaft (whose rotation is transmitted to the wheels to drive the car).

By contrast, a rotary engine performs a combustion for every revolution of the eccentric shaft. That means you only get the sounds that are produced within one revolution. In other words, the same number of combustions yields different quantities and intervals of sound.

And the biggest difference is that reciprocating engines emit what’s known as half-order noise with each combustion, while rotary engines do not.

Sorry to geek out, but this really gets at the crux of how we hear the sounds, so please bear with me for a bit (laughs).

Geeking out on sound

This was the first we’d heard of “order” sounds. If they really are the essence of how we hear sounds, we needed to learn more. Iwata was happy to oblige.

Iwata

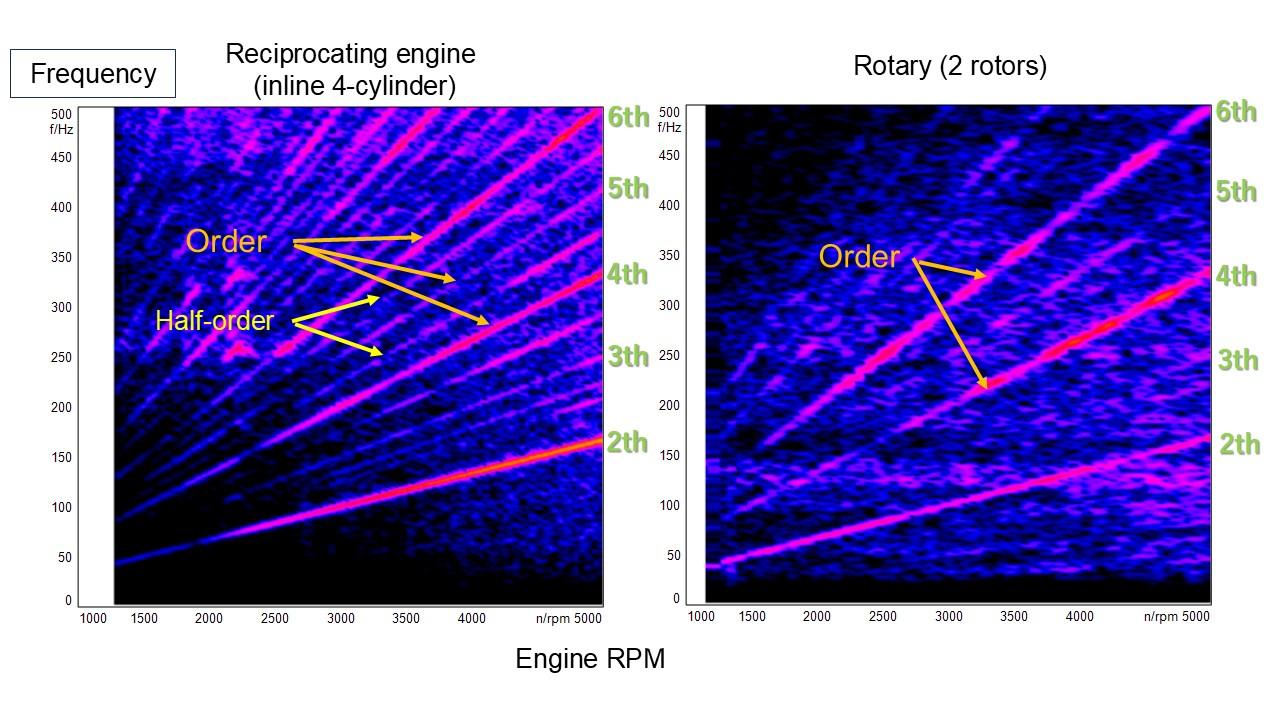

These graphs show a distribution of vibration and other noises with respect to engine speed, with RPM on the horizontal axis and frequency on the vertical. Each of the reddish straight lines that rise from left to right in proportion to engine RPM represent sounds of a given “order.”

On the left, we have an inline four-cylinder reciprocating engine, and on the right is a twin-rotor RX-8.

When you compare them, the rotary engine has fewer lines, and the graph looks less cluttered.

As you can see, reciprocating engines have additional lines between the second, third, and fourth orders, and so on. These are known as half-order noise. Simply put, they add extra clutter to the sound.

The orders in the graph represent the sounds emitted in a series of pulses through the cycle of intake, compression, combustion/expansion, and exhaust. So how does the presence of half-order noise affect how we hear engine sounds?

First, let us briefly explain the mechanism of sound.

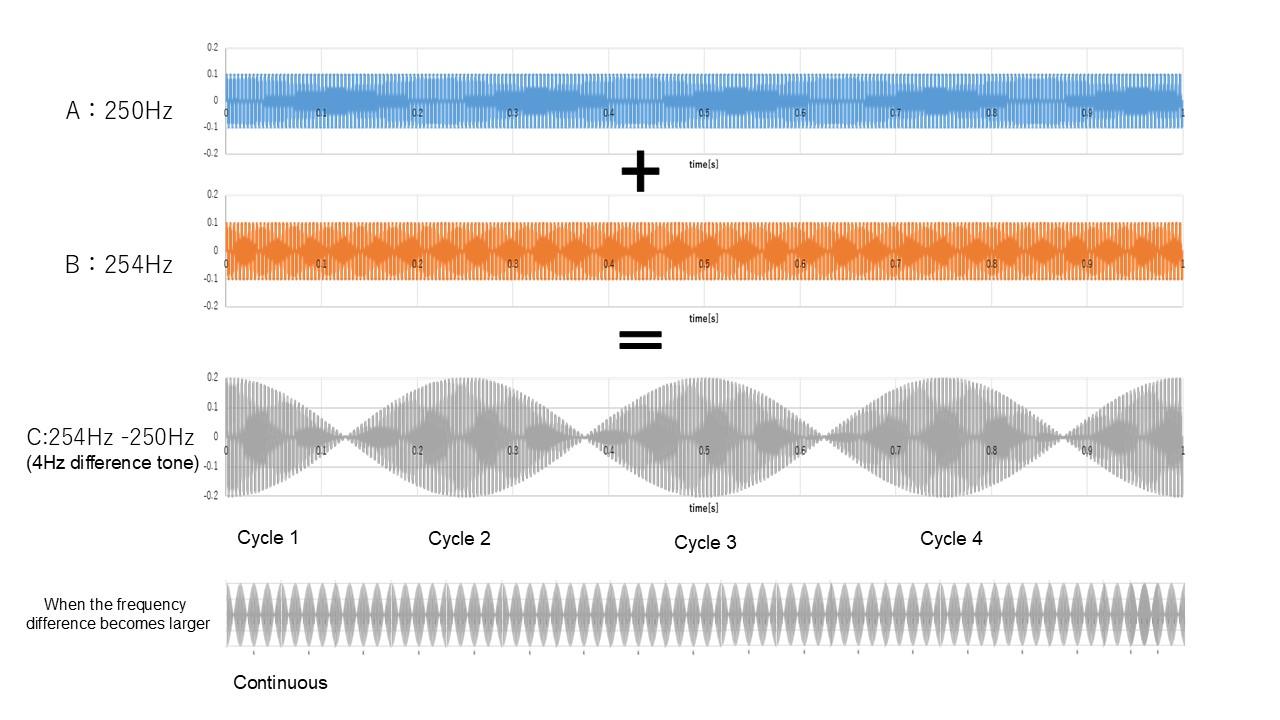

When a person hears different frequencies at the same time (A & B in the diagram below), they also hear an additional sound, the difference tone (C), whose frequency is the difference between the two. All of these are perceived as a single sound.

Measured in hertz (Hz), a sound’s frequency represents the number of vibrations per second. A higher frequency indicates a higher pitch.

For example, a sound created by combining 250Hz and 254Hz produces a difference of 4Hz (254-250). As seen on the graph, this difference tone can be heard as four cycles of swelling and fading per second.

When the difference between the two sounds is larger, the difference tone can no longer be heard as individual cycles but rather as a continuous high pitch.

In other words, people perceive such difference tones mainly as sounds.

In the case of a reciprocating engine, we simultaneously hear the base order sounds along with half-order noises that are close in frequency, resulting in a pulsing sound with discernible difference tone cycles.

(Recent reciprocating engines are tuned to eliminate half-order noise. Look forward to a more in-depth explanation in our next article)

Rotary engines, meanwhile, do not generate half-order noise, creating large frequency differences and continuous, high-pitched difference tones. This gives them an uncluttered, clean sound.