Toyota's Plants: Inheritance & Evolution is a series introducing the history and future vision of individual production facilities. This time we retrace the Honsha Plant's journey since its founding.

Cars people can actually buy

It is not enough to simply make vehicles; they must be sold at a price customers can afford. Only then does the industry meet people’s needs. Kiichiro Toyoda emphasized this point and was dedicated to reducing the costs of production.

To achieve this goal, he advocated the Just-in-Time principle that is now a core component of the Toyoda Production System.

The concept predated the Koromo Plant and was described as follows:

Kiichiro

I believe that the most important thing is to ensure that there is neither shortage nor excess, that is, to ensure that there is no excess labor and time for the designated production. To have no waste nor excess. It means not having to wait for parts to be circulated around. For Just-in-Time, it is important that each part be ready 'just in time.' This is the first principle of increasing efficiency.

Make only what is needed, when it is needed, and in the amount needed. This keeps costs down and prevents wasting of parts, which at the time were even more valuable than today due to the scarcity of raw materials.

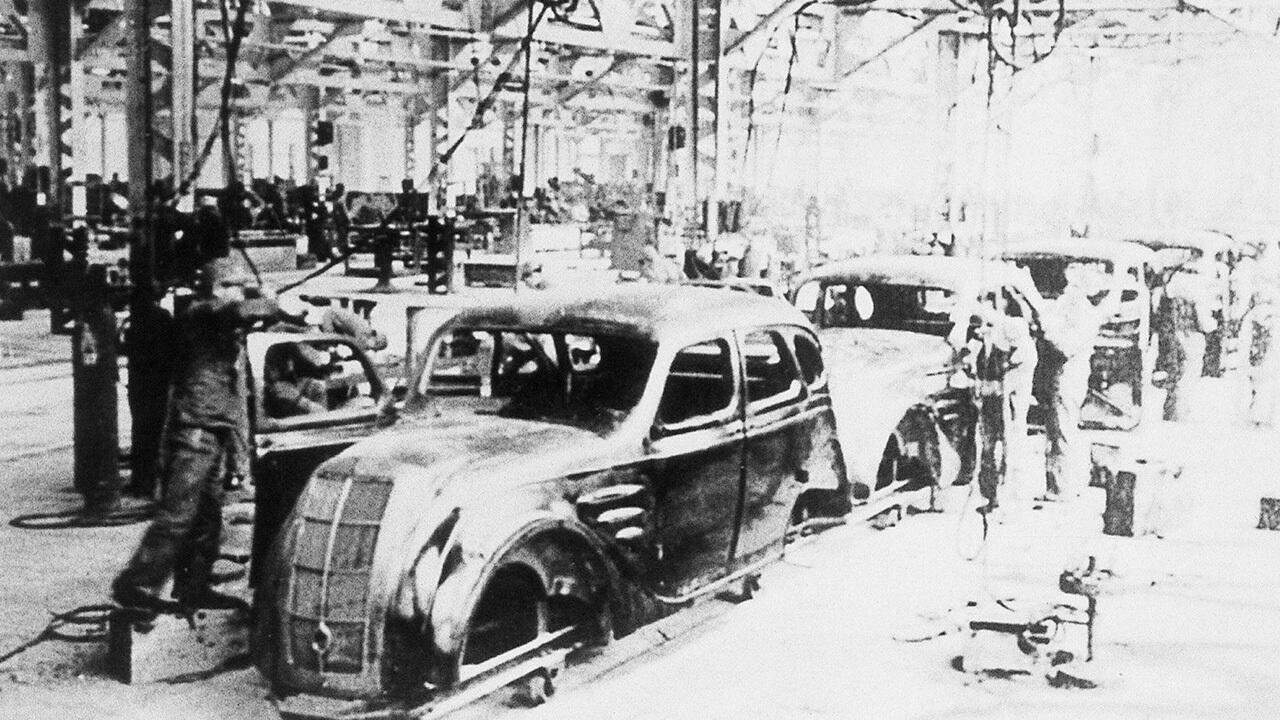

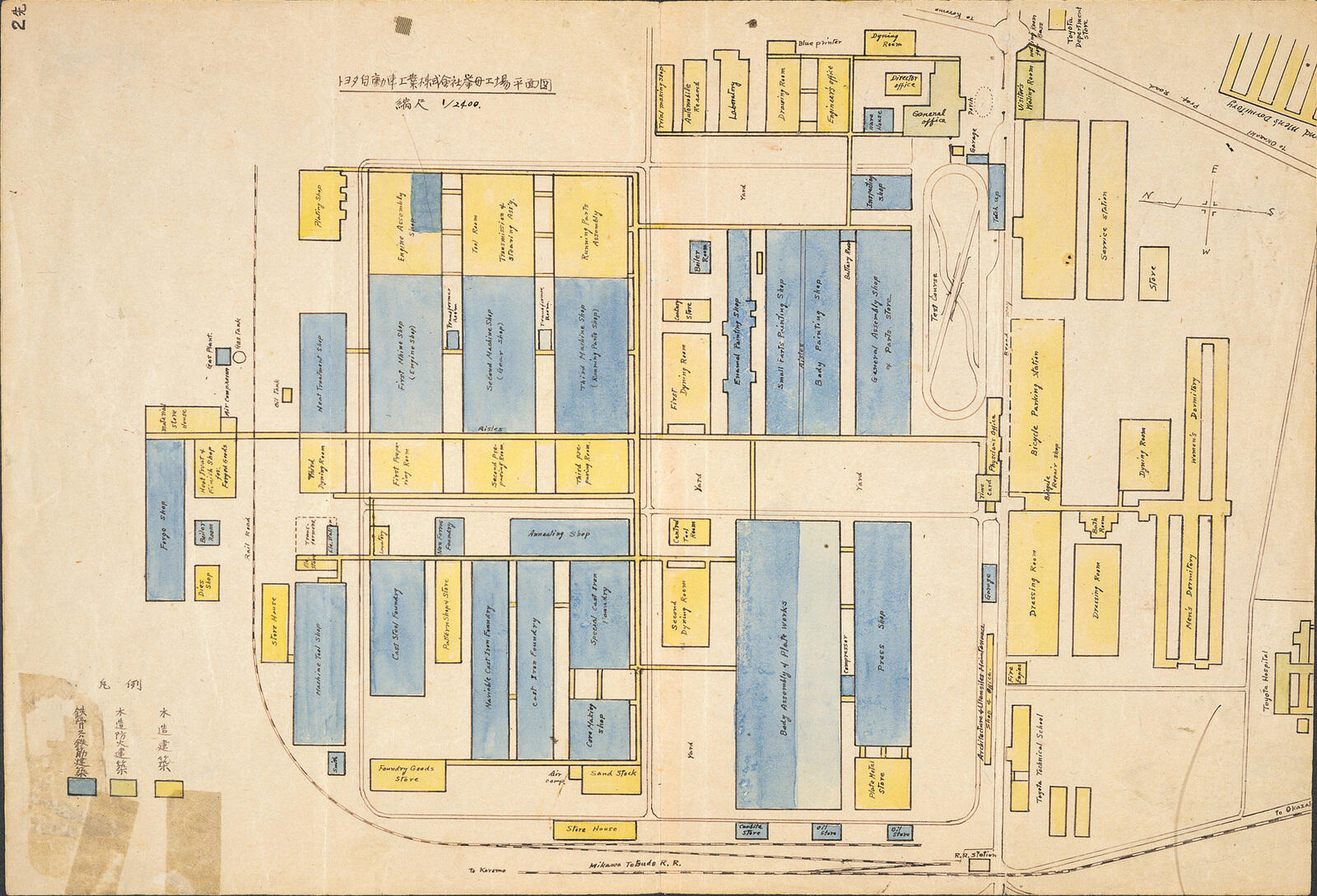

As seen below, the Koromo Plant’s design turned this concept into reality.

Working our way down from the top of the diagram, we start with metal fabrication (forging and casting), then go through the other processes such as parts assembly, painting, and body assembly.

In other words, the plant is arranged to ensure there is no waste in conveying goods and information, as they flow smoothly from procurement to assembly without delay.

At Koromo, this Just-in-Time approach enabled Toyota to produce 2,000 vehicles a month.

Chasing dreams

As it happened, Kiichiro Toyoda dreamed of more than just automobiles.

With the completion of the new plant, he also began researching aircraft, seeking to expand into yet another industry.

The town of Koromo had a large airfield that was ideal for conducting research. Kiichiro tried to build an aircraft that flew by rotating a propeller, much like a modern-day helicopter.

Driven by a tremendous passion, he went so far as to set up a dedicated unit for conducting aircraft research, for which he purchased planes sold off by the Japanese Navy.

From automobiles to aircraft, the Koromo Plant sustained Kiichiro’s ventures into uncharted territory. Along with the history, this role has been passed down to the current Honsha Plant.

Plant General Manager Eri

Since starting operations in 1938, the Honsha Plant has served as a trailblazer in new technologies. We named this role the “phase in,” and it remains our unwavering mission.

To “phase in” is to venture into new territory, but you can also think of it as turning dreams into reality.

The Honsha Plant’s more than 80 years of history began with precisely that: venturing into the unknown frontier of automobiles and aircraft. That is why we continue to pioneer new technologies that will shape Toyota’s future.

Our genba fosters a “leave it to us” attitude and a strong appetite for taking on new challenges.

As Plant General Manager Eri explains, today, the Honsha Plant fulfills the function of taking on new technologies and methods in the experimental or prototype stage and then sharing its expertise with other plants and countries around the world.

An adventurous spirit that dates back more than eight decades continues to fuel the Honsha Plant to this day.

A vision unbroken by war

Just as Kiichiro looked set to realize his dream of filling the country’s roads with domestically produced cars and its skies with aircraft, Japan was plunged into war.

Until the war ended in 1945, Toyota was designated as a munitions manufacturer and restricted from operating freely.

The Koromo Plant, which produced military trucks, had around a quarter of its facilities destroyed by air raids. After the war, many employees left the company, reducing a team of some 9,500 to about 3,700. It would take time for Toyota to regain its prewar output.

Even amid the ruins and devastation, Kiichiro never stopped taking on new challenges, which included developing new smaller car engines in preparation for the day when Toyota could freely make automobiles.

However, the company struggled financially, and in 1950 Kiichiro resigned as president following a labor dispute. Toyota’s business subsequently recovered with demand fueled by the Korean War. The management team asked Kiichiro to return, but he passed away on March 27, 1952, at the age of 57.

Three years later, in 1955, Toyota released Japan’s first genuine domestically produced passenger car, the Toyopet Crown, the first-generation Crown. Beloved nationwide as the country’s first truly homegrown vehicle, it was used by everyone from private households to government officials and taxi fleets.

Kiichiro’s dream of “making cars with Japanese ideas and skills” was finally on the verge of becoming a reality.

Keeping the history and spirit alive

Production of the first-generation Crown later shifted from Koromo to the newly built Motomachi Plant. Since then, Toyota has continued to make a wide range of vehicles, establishing production facilities in 27 countries and regions outside Japan.

The Koromo Plant was born out of Kiichiro Toyoda’s desire to establish a domestic auto industry. Renamed the Honsha Plant in 1959, it has remained at the forefront of Toyota’s endeavors, handling the assembly of hybrid units for the original Prius and producing fuel cell stacks for the Mirai.

Plant General Manager Eri is dedicated to conveying Kiichiro’s resolve to future generations.

Plant General Manager Eri

Kiichiro Toyoda had an unfathomable drive to develop an automobile industry in Japan. As the plant’s general manager, I feel a profound sense of duty to pass this on to future generations.

To keep that mindset alive, we must keep pushing ourselves to take on new challenges. This commitment is embodied in the words Honko Tamashii (Honsha Plant Spirit), which you can find displayed throughout the facility.

While it is important to nurture young technicians who will create our future, we must also pass on the Honko Tamashii imbued with the plant’s history. To me, that’s what Inheritance and Evolution mean for the Honsha Plant.

Kiichiro’s resolve continues to burn bright at the Honsha Plant.

Looking to the future, what kind of evolution will the plant pursue? We’ll cover this question in depth in our next article.

Toyota Honsha Plant

Location: 1 Toyota-cho, Toyota City, Aichi 471-8571

Start of production: November 3, 1938

Site area: 599,000 m 2

Employees: 1,940 (as of March 2024)

Main products: Engine and transmission parts, Mirai fuel cell stacks, Prius hybrid units, Land Cruiser frames, etc.