Toyota's Plants: Inheritance & Evolution is a series introducing the history and future vision of individual production facilities. This time we retrace the Honsha Plant's journey since its founding.

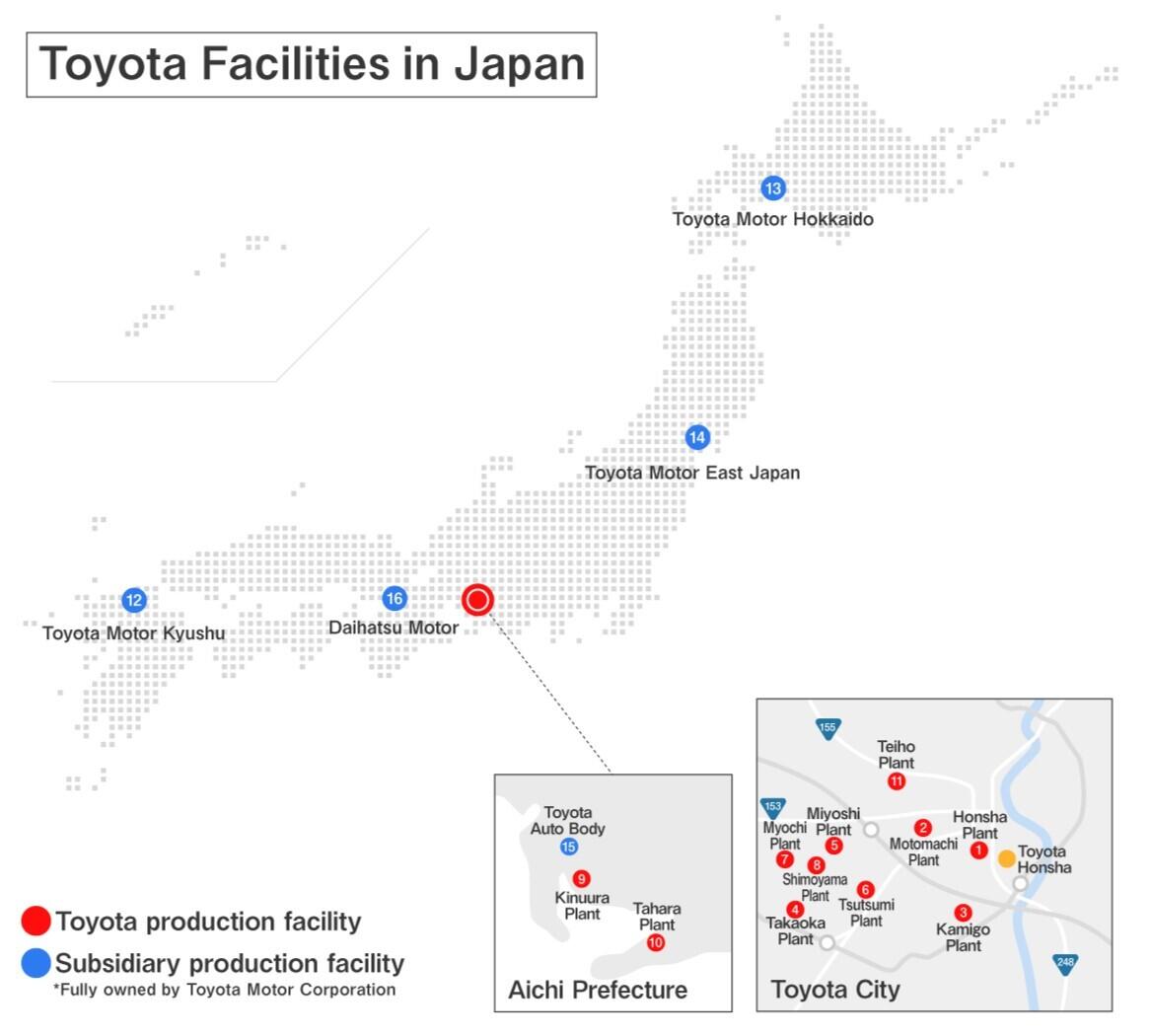

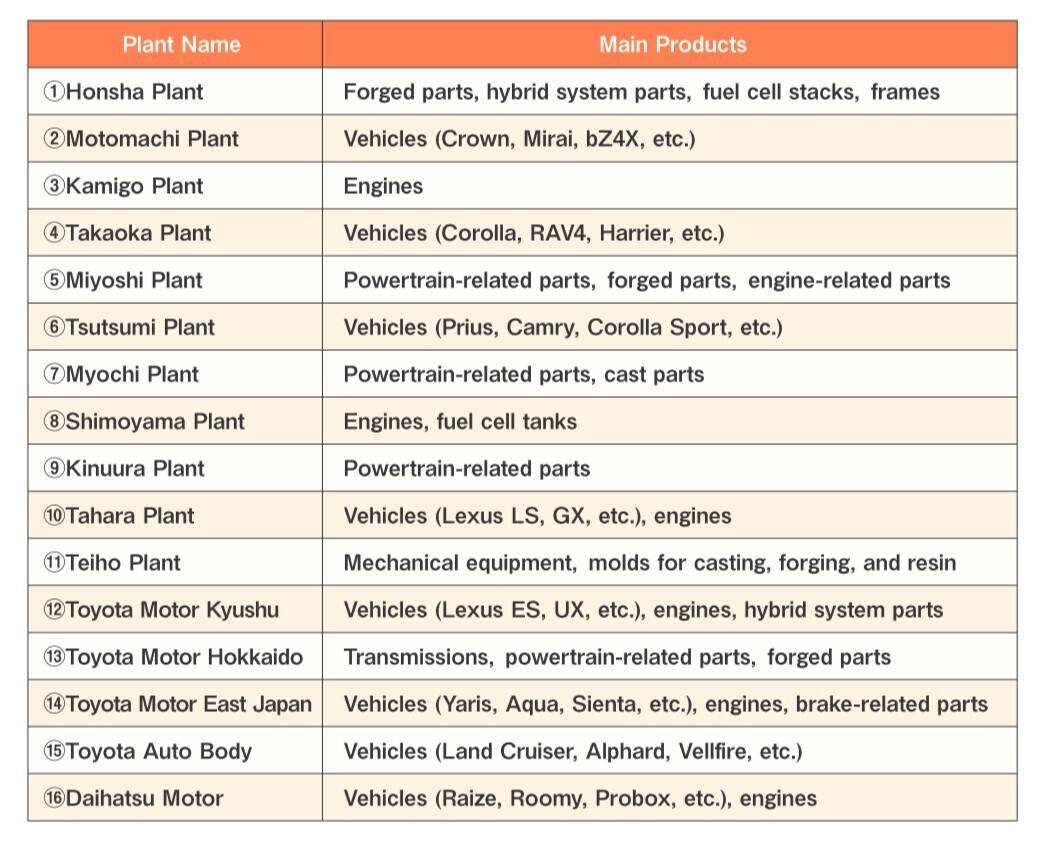

Let’s start with a question: how many plants does Toyota Motor have in Japan?

The answer: eleven. Yet this number doesn’t include the plants of fully owned subsidiaries that handle carmaking for Toyota and Lexus, with facilities stretching across Japan from Hokkaido to Kyushu.

Not all of these plants assemble finished vehicles; some specialize in producing engines, transmissions, and other automotive parts.

And while it may be hard to tell one Toyota plant from another, each has its own unsung history and remarkable stories. What’s more, as the company seeks to transform the future of cars, every plant is undergoing its own evolution.

This new series, Toyota’s Plants: Inheritance & Evolution, will delve into the unique character of each facility, highlighting the history of each plant up to the present, as well as its vision for the way forward.

We begin with the Honsha Plant, Toyota’s oldest. For this article, we will focus on “Inheritance,” retracing the plant’s history dating back to the company’s founding.

As the name suggests, the Honsha Plant is located at the Toyota Motor Corporation honsha, or head office (1 Toyota-cho, Toyota City, Aichi). It produces a wide range of components, from engine and transmission parts to Mirai fuel cell stacks, Prius hybrid units, and Land Cruiser frames.

Standing on the same site as the main office building that houses Toyota’s personnel and accounting departments and the technical center with its many development and design units, how has the Honsha Plant’s history unfolded?

The plant where it all began

November 3, 1938, marked both Toyota Motor Corporation’s founding* and the completion of the Koromo Plant (the current Honsha Plant), a facility for start-to-finish mass production of domestic cars.

*Although Toyota Motor Co., Ltd., the forerunner of Toyota Motor Corporation, was established on August 28, 1937, the company’s founding date was designated to coincide with the Koromo Plant’s completion.

At the time, automobiles were luxury goods. The few that could be spotted on city streets were mostly American-made. Though several Japanese companies were engaged in manufacturing domestic vehicles, none were set up for mass production.

Given the circumstances, Toyota’s foray into the auto industry might be considered reckless. However, company founder Kiichiro Toyoda was determined to make cars “with Japanese ideas and skills.”

Today, Toyota has manufacturing facilities in 27 countries and regions outside Japan. So how did that first mass-production plant come to be?

The age of automobiles comes to Japan

To uncover the roots of Kiichiro’s ambitions for Japan’s automobile industry, which led him to establish the Koromo Plant, we need to wind the clock back to 1921.

While working for Toyoda Boshoku, which had been set up by his father Sakichi, Kiichiro toured America for the first time. There he saw roads packed with automobiles, the backbone of people’s mobility.

Kiichiro returned home convinced that the age of automobiles would one day come to Japan, and that the country needed an auto industry to join the world’s leading nations. Then on September 1,923, the Great Kanto Earthquake struck.

With the railroads devastated, American-made trucks were converted into buses to serve as a means of transportation for recovery efforts. As one of those affected by the disaster, Kiichiro witnessed the utility of automobiles firsthand.

In 1933, he established an automotive division within Toyoda Automatic Loom Works (founded by Sakichi; now Toyota Industries). When not making looms, Kiichiro and other like-minded members spent their time dismantling and studying vehicles imported from the United States.

Setting up a makeshift prototype plant (located within the current site of Aichi Steel’s Kariya Plant), they figured out a way to produce a homegrown vehicle. This place, where the craftspeople first got their hands dirty making cars, is the origin of the Honsha Plant.

With the expertise gained, in 1936, Kiichiro built a new assembly plant (a predecessor of today's Toyota Auto Body). Two years later, in 1938, the company constructed the Koromo Plant as a full-scale mass-production facility.

Mending a broken Koromo

The site chosen for this new plant was the town of Koromo in Aichi Prefecture. It is now part of Toyota City, home to the company’s head office.

Koromo had previously thrived through silkworm raising and silk manufacturing, but these key industries withered during the Great Depression of the 1930s. Having fallen on hard times, the town was derided as Yabure (broken) Koromo, playing on the fact that its name is a homonym of the Japanese word for “garment.”

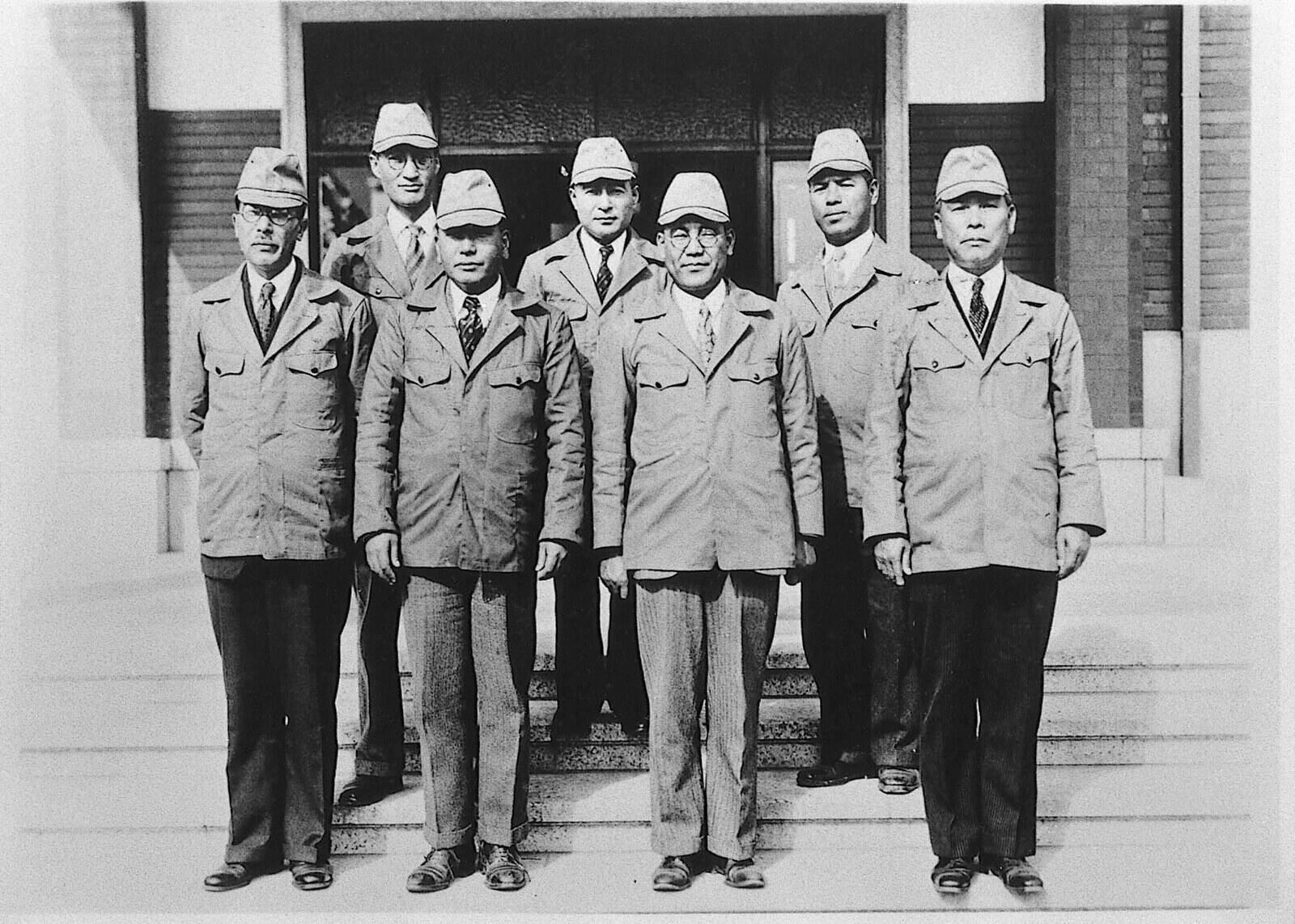

As then-Mayor Juichi Nakamura sought to mend the town’s fortunes, Kiichiro Toyoda offered to purchase land for his plant.

The site was a vast, barren plain known as Ronchigahara, with a nearby river ideal for generating hydroelectric power. Koromo also offered many other advantages as a location, not least access to the Mikawa Railway (now the Meitetsu Mikawa Line) that could be used to transport materials.

Keen to give Koromo hope in the form of automobiles, Mayor Nakamura accepted the proposal.

Kiichiro had this to say about constructing the plant:

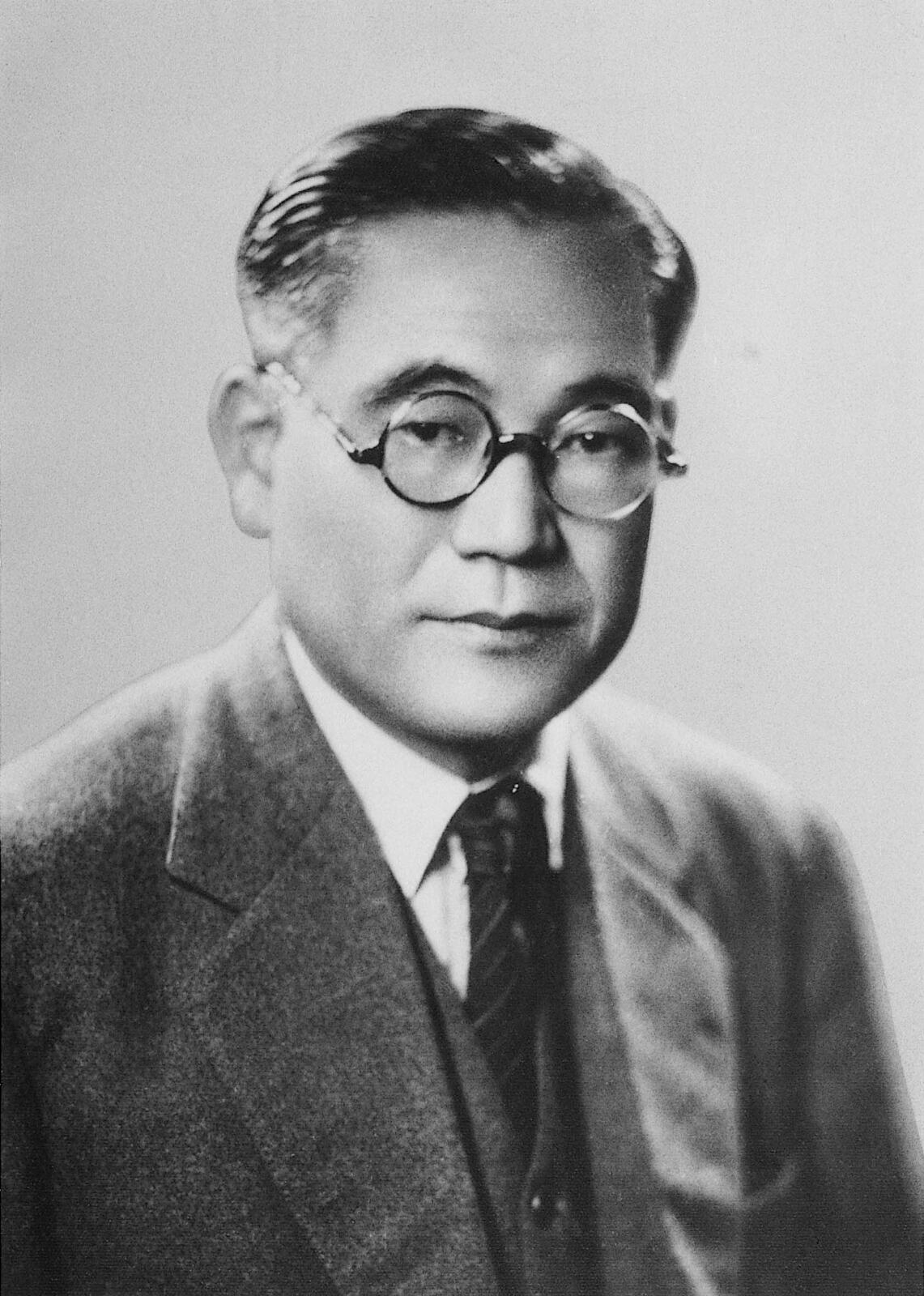

Kiichiro Toyoda

Starting an automobile industry is an extremely difficult undertaking. I was fully aware of this reality when deciding to embark on this project.

Naturally, I intend for my plan to leave no stone unturned. What we are building here is a full-scale mass-production plant, which may come with its own perils.

Yet even if Toyoda fails in this venture, others will not abandon the plant we build. The facilities will be used by a second group of entrepreneurs, or a third. I therefore believe that, while building this plant can be a positive force in Koromo’s development, it will never be a negative one.

With that, Toyota Motor Co., Ltd. was established in 1937. The following year, the Koromo Plant began operating on November 3, and the date was adopted to mark the company’s founding.

With the assistance of Mayor Nakamura, who was eager to revive his town, a mass-production plant was born. In building the facility, Kiichiro wanted to bring happiness to both employees and townspeople alike, to ensure they would get behind his efforts.

Committed to this idea, he always sought to contribute to the local area beyond creating jobs.

According to Yoshinori Eri, the Honsha Plant’s current general manager, this community spirit still lives on today.

Yoshinori Eri, Plant General Manager

The neighborhood around the current Honsha Plant includes lots of company housing, and the Toyota Memorial Hospital. The founding spirit of community coexistence ensured that the plant grew together with the town.

If Kiichiro Toyoda had not met Koromo Mayor Juichi Nakamura, the plant would not have been built here. Even now, in this time of once-in-a-century transformation, we must carry on that original community-minded philosophy.

Every year, a ceremony is held to honor the lifetime achievements of the two men who laid the foundations for today’s Toyota and Toyota City.

When the Koromo Plant officially opened, Kiichiro’s challenge went beyond merely making automobiles.