A series showcasing Toyota's research in non-automotive fields. This time: who's ready for stone oven pizza?

Naturally, building the world’s first hydrogen-powered stone oven came with its fair share of risks. But in the development genba, risks are something to be understood, not feared.

Atsushi Shirakawa, Group Leader, Prototype Development Section, Raw Material Development Div.

Initially, building a hydrogen cooker felt rather scary. That’s why we make sure to ask Rinnai staff whether we’re doing things right.

Checking as we go allows us to craft safe equipment and products. Everything has its risks, but the key is to understand them and follow procedures. By doing so, we can create products that are safe and make customers happy.

Monozukuri skills passed down over many years were brought into new fields and evolved, resulting in the world’s first stone oven powered by hydrogen. The collaboration was also a great learning experience for both companies.

“Rinnai has an intimate knowledge of what customers look for in cooking appliances, so they were able to teach us everything,” reflect members on the Toyota side. Meanwhile, the Rinnai staff had this to say:

Shusaku Hayashi, Advanced Development Section.,R&D Headquarters,Rinnai

What surprised me was the speed of Toyota’s work. They cycle through the trial-and-error process within a short time span. The “start by doing” approach gives you various insights that help you grow, and I feel that my work is faster.

The more people you have on your side, the more you can achieve. Not only that, they can also help you learn something new.

But wait, there’s more—hydrogen grillers and kamado

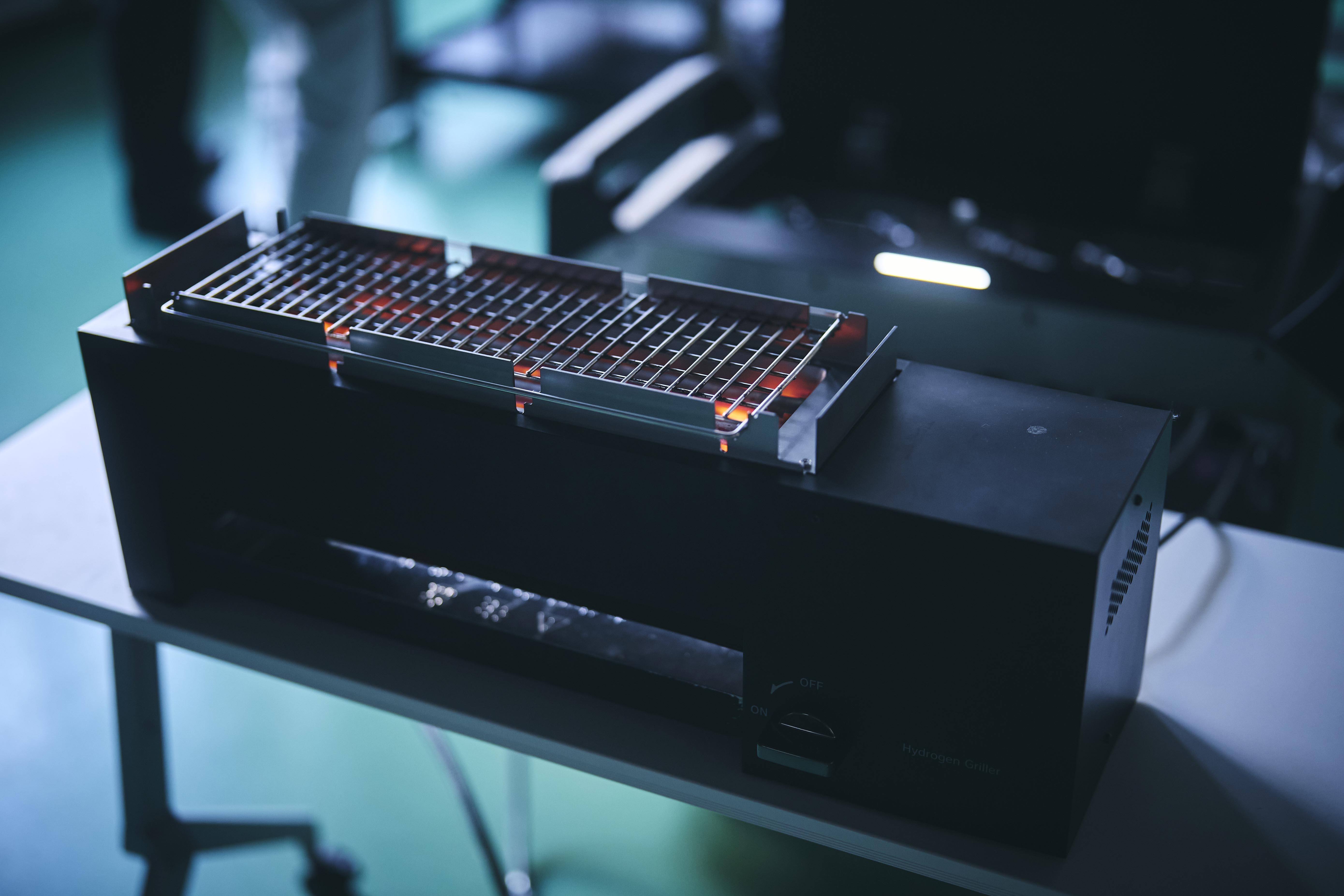

The stone oven is not the only hydrogen cooker being developed. This hydrogen griller has been showcased at Rally Challenge and other motorsport events.

“It’s great, things don’t get too charred on the grill,” commented the head chef at the Fuji Speedway Hotel, which opened in the fall of 2022. And next up, we have the first look at a hydrogen stone kamado.

“Kamado are Japan’s time-honored cookers. We respected the traditions and culture of using fire, passing them on to the next generation in the form of hydrogen,” says Takahashi, the developer. Here too we can glimpse Toyota’s emphasis on inheritance and evolution.

Another project member shared these words:

Hiroyuki Yamaguchi, Assistant Manager, Technical Demonstration Group, Hydrogen Factory

Our task is figuring out how to raise the value of food with hydrogen. Since hydrogen, conventional gas, and charcoal each have distinct characteristics, it should be possible to choose the best form of energy for specific ingredients or dishes. We see this as part of the multi-pathway approach to carbon neutrality.

We can also quantitatively measure the effects on ingredients and unravel the mechanism. Figuring out how mechanisms work is precisely the job of engineers.

While culinary science is studied at many universities, getting engineers involved in research may open up vast possibilities for food tech.

We visited the genba after hearing about employees baking pizzas on the job. Their faces revealed the conviction that “you can’t make an enjoyable future without enjoying yourselves along the way.” This world-first challenge is putting smiles on the faces of creators and food lovers alike.