A series showcasing Toyota's research in non-automotive fields. This time: who's ready for stone oven pizza?

In the middle of a workday, an employee is busy rolling dough, sprinkling cheese, and baking pizzas in a stone oven. His expression is serious. “I often make pizza at home too,” he says. “I’ve gotten pretty good at it.”

Why are Toyota staff spending their time making pizza? As it turns out, they even built the stone oven. What in the world is going on?

The world’s first hydrogen-powered stone oven

The reason why Toyota employees are turning into pizza chefs lies in this strange oblong. They are testing out the world’s first hydrogen-powered stone oven, jointly built with renowned gas appliance maker Rinnai.

As an energy source, hydrogen opens up all sorts of possibilities; it also holds a great deal of potential in the kitchen.

Hydrogen has a high combustion temperature. As it burns, it combines with oxygen to produce steam, making dishes crispy on the outside and succulent inside.

For example, take things like mushrooms and vegetables.

While these ingredients tend to dry out on a wood or charcoal BBQ, hydrogen cooks more quickly, leaving them bursting with moisture and delicious flavors. Even so, why is Toyota cooking with hydrogen?

Starting close to home

We spoke to project members from Toyota and Rinnai about the hydrogen stone oven’s development process. They all agree that “making hydrogen feel like part of everyday life is a crucial first step in creating a hydrogen society.”

Atsushi Shirakawa, Group Leader, Prototype Development Section, Raw Material Development Div.

At present, we don’t have hydrogen stations near our homes. While hydrogen still feels unfamiliar, we felt cooking was a good opportunity to use it in daily life. Hopefully, food can be a springboard for expanding the horizons of our hydrogen society.

This hydrogen stone oven was unveiled at last year’s Japan Mobility Show, serving up freshly baked pizza and croissants for visitors.

These proved a big hit with children at the event, with many eager to try them again or research the oven for their school projects. “This is the first time kids have shown interest in hydrogen,” commented a surprised Rinnai representative.

Tetsuya Nakajima, Assistant Manager, Products Development Dept., Raw Material Development Div.

Since the Mobility Show, my kids have been asking for more hydrogen-baked croissants (laughs). People may think we’re just messing around making pizzas at work, but we are determined to pave the way for a hydrogen society.

At the same time, creating the world’s first hydrogen-powered cooker also brings plenty of challenges. The relevant safety standards do not yet exist.

Tatsuyuki Hayashi, Products Development Dept., Raw Material Development Div.

As yet, there is no certification system for hydrogen cooking appliances. The lack of standards adds another layer of difficulty to monozukuri. Without any set answers, we have no choice but to figure things out for ourselves.

One of Rinnai’s developers, Masao Nonoyama, also recalls trouble along the way.

Masao Nonoyama, Advanced Development Section.,R&D Headquarters,Rinnai

We discussed the creation of safety guidelines and other essentials with Toyota, identifying and resolving issues while presenting our work at various events.

With no existing answers, the only way forward is to take action. Doing so allows you to see the issues and make improvements. Such steady efforts will eventually forge a new future.

Does carmaking expertise apply to hydrogen stone ovens?

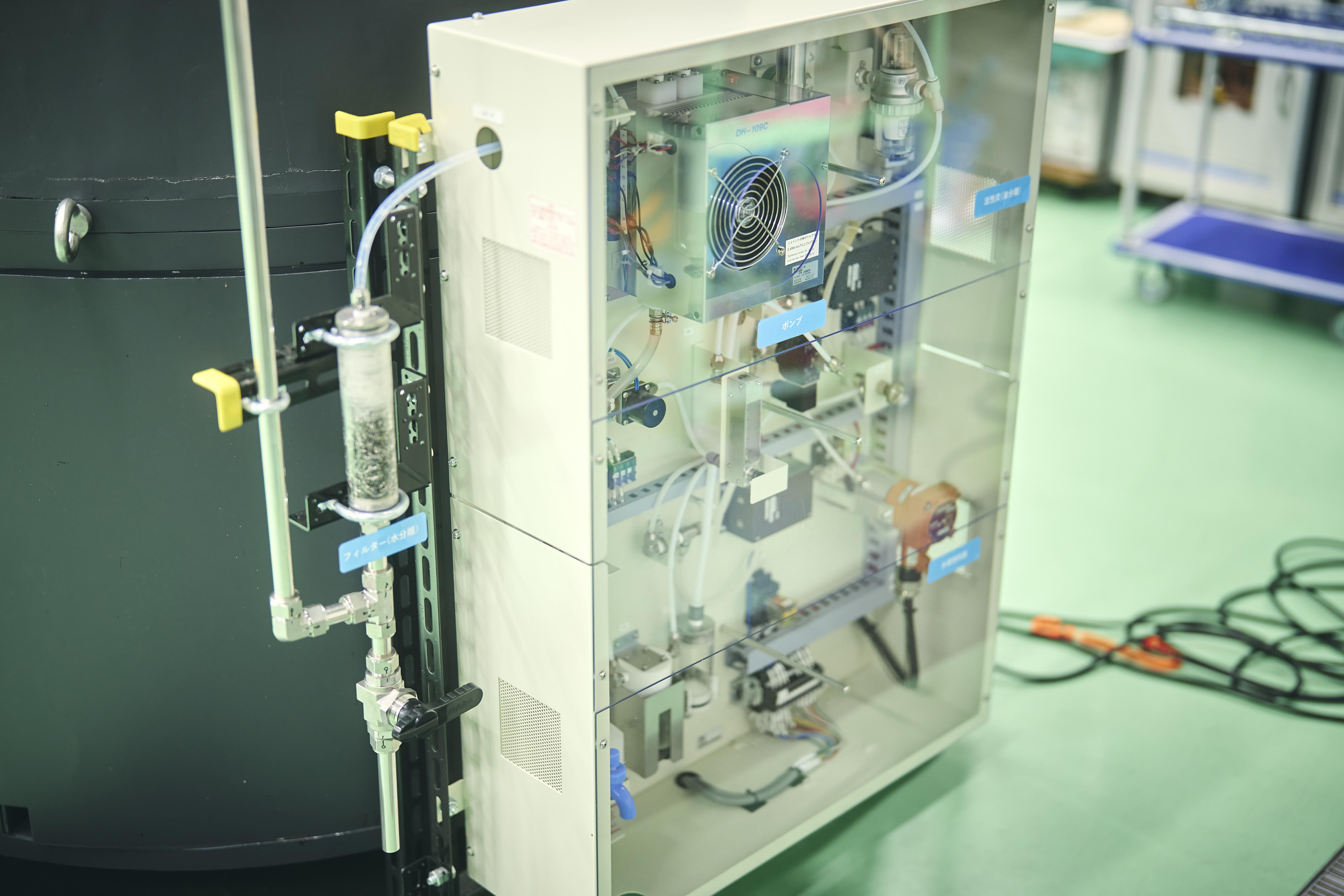

To create a safe hydrogen cooker, the team harnessed both Rinnai’s strengths in combustion technologies and Toyota’s long-established carmaking expertise.

One example was the technologies used to safely control combustion furnaces and paint-drying ovens in the car manufacturing process. The project also drew on technology for safely supplying and monitoring hydrogen, which had been honed for the Mirai fuel cell vehicle.

Kenji Takahashi, who long served as a group leader at Toyota’s plants, shared his genba perspective.

Kenji Takahashi, Senior Expert, Products Development Dept., Raw Material Development Div.

On the manufacturing floor, we manage daily production by envisioning the various possible risks. Similarly, in development projects, we also identify the most likely stumbling blocks in advance and then deal with them in order of priority.

In these cases, I draw on my experience from the manufacturing genba and always try to creatively devise improvements. The monozukuri capabilities and work practices we have honed on the front lines can be applied in all sorts of places.

Engineering skills and hands-on genba expertise—both of these elements drive Toyota’s monozukuri. On the next page, we unveil a hydrogen cooker that has not yet been seen anywhere else!