Batteries with a 1,000 km cruising range and FC systems that combine fuel efficiency with longevity and lower costs were among the next-generation technologies unveiled by Toyota for future release.

[Hydrogen] New fuel cells build on 30 years of development

Toyota has thus far provided intermittent updates on its hydrogen efforts.

At the workshop, Hydrogen Factory President Yamagata emphasized a coordinated approach to commercialization, spanning everything from development and production to sales. “We will pursue sufficient volume to offer affordable products,” he explained.

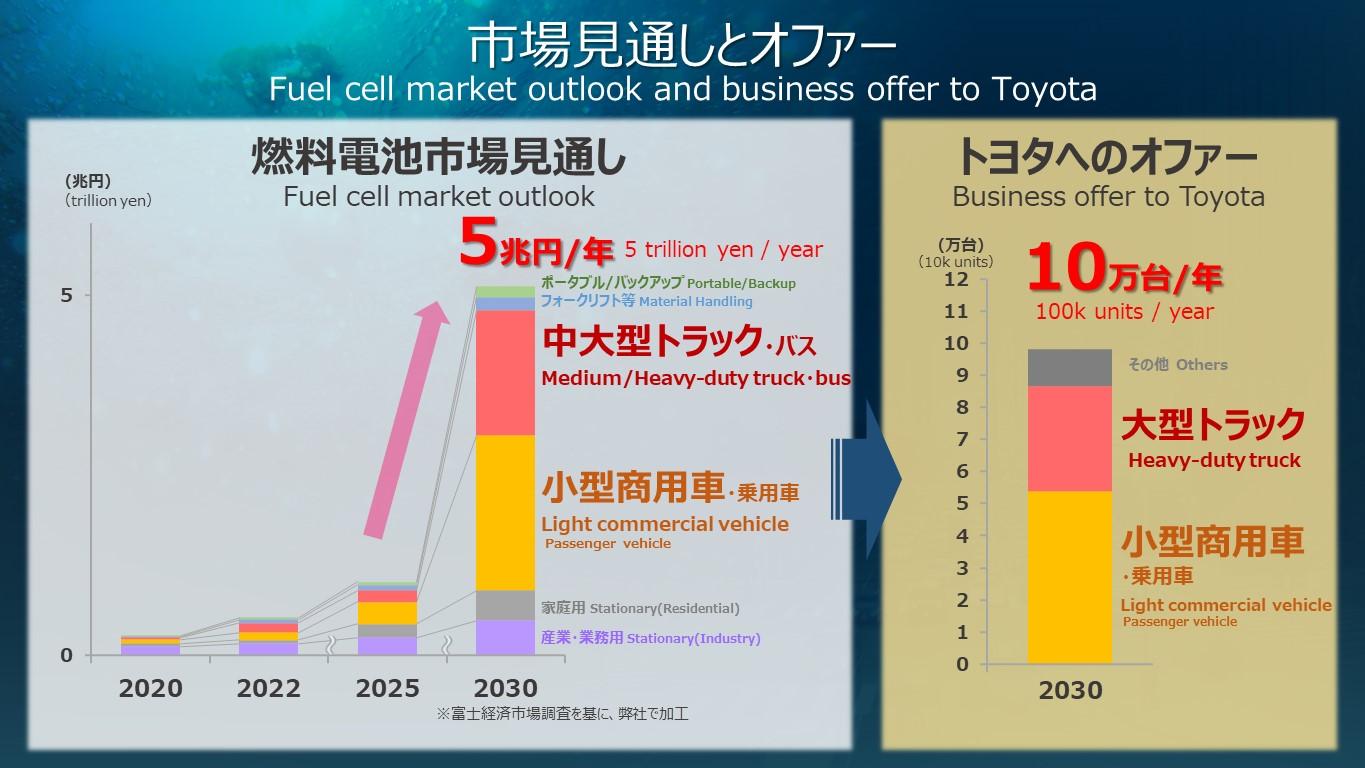

President Yamagata also indicated that Toyota had received offers for 100,000 vehicles’ worth of fuel cells by 2030 and presented a vision for expanding the market through commercial vehicles.

Unfortunately, hydrogen fuel cell units, and hydrogen itself, remain expensive.

To promote the more widespread adoption of hydrogen, the event’s exhibition space featured a next-generation fuel cell (FC) system offering improved driving performance and fuel economy for commercial vehicles, alongside initiatives to reduce manufacturing costs for onboard tanks. Technologies for producing hydrogen were also explained.

[Hydrogen] Next-gen FC systems for commercial vehicles

Fuel cell systems contain stacks of circuits embedded in thin sheets—the “cells”—which generate electricity through chemical reactions between oxygen and hydrogen.

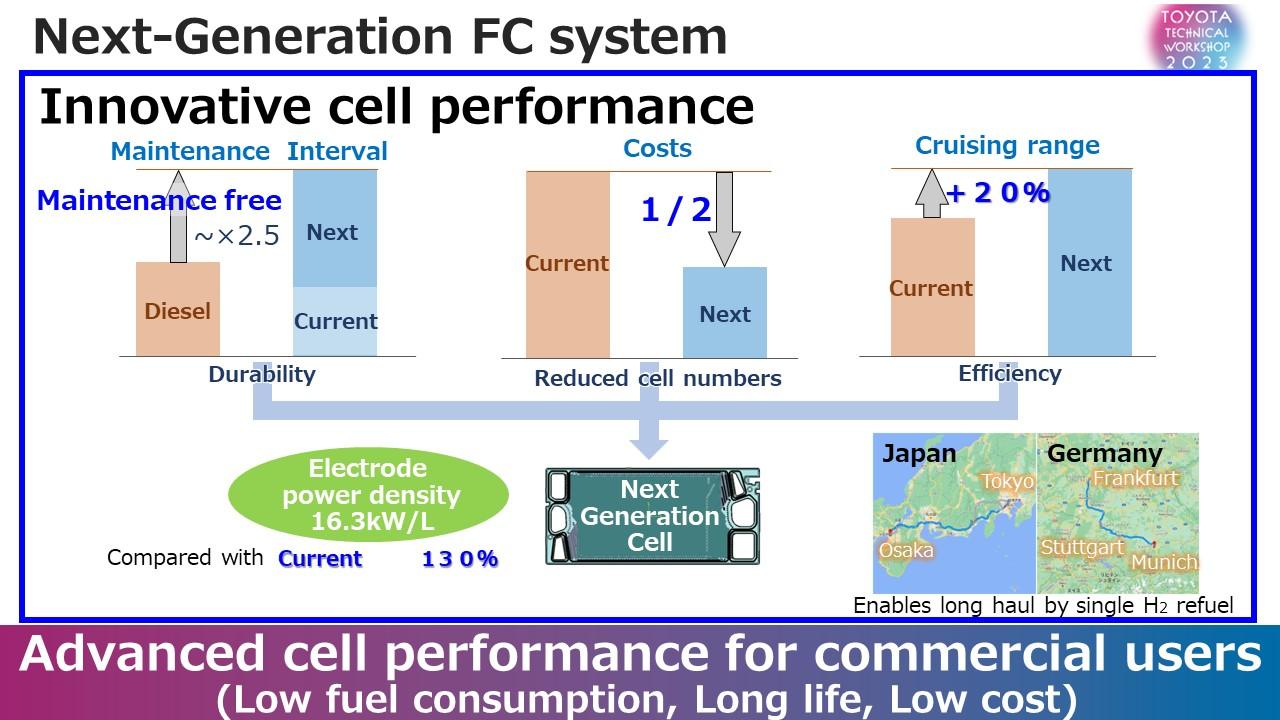

On display at the workshop were next-generation cells that improve existing generating capacity by 30%.

On the durability front, FC vehicles could stay on the road 2.5 times longer than standard diesel machines before requiring maintenance, making them virtually maintenance-free over the life of a vehicle.

Compared to current cells, Toyota’s next-generation systems also halve the cost of fabricating a stack and increase range by 20%. This improvement would make it possible to travel between Tokyo and Osaka without refueling.

These next-generation cells reflect the expertise that Toyota has built up over 30 years: real-time measurement and analysis of the processes occurring within cells, simulations for nanoscale mapping of chemical reactions, and precision coating of the catalysts that drive these reactions.

Toyota’s advanced technical capabilities help to inhibit deterioration caused by corrosion and other factors, lowering the cost of materials needed for manufacturing. These highly competitive next-generation cells are slated for release in 2026.

[Hydrogen] Using carmaking technologies to produce hydrogen

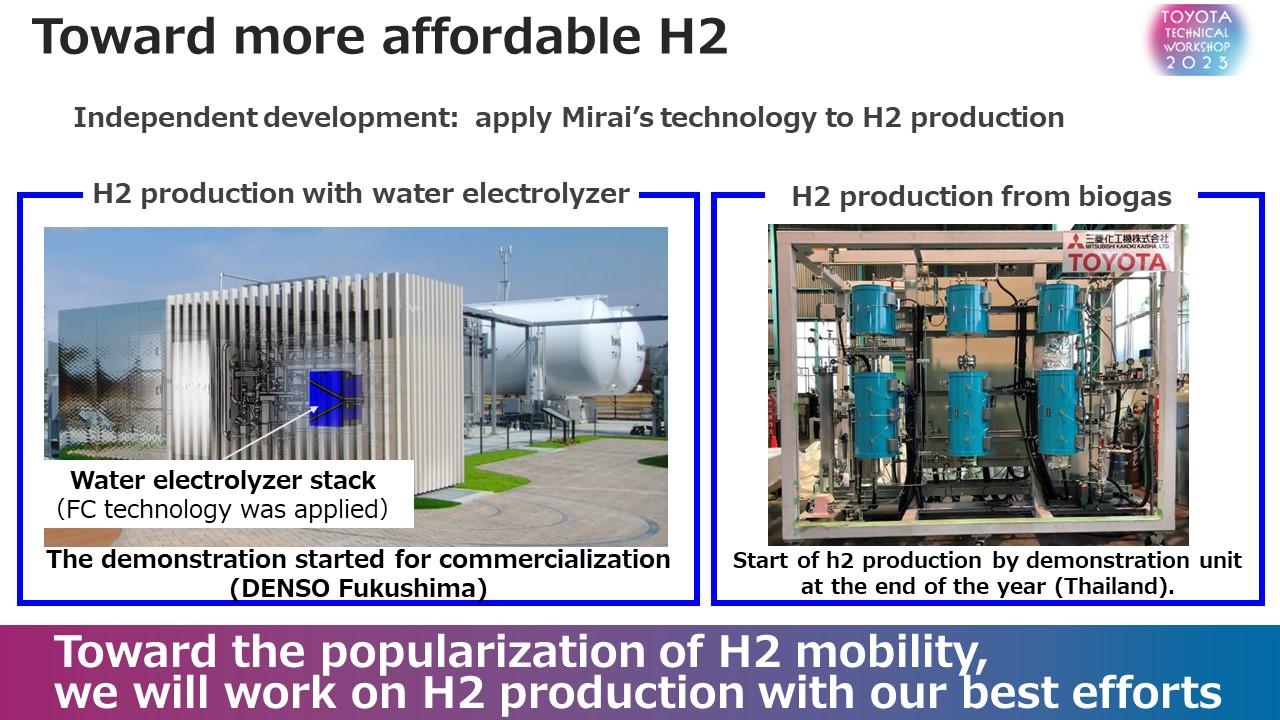

Alongside the performance improvements of next-generation FC systems, Yamagata also highlighted Toyota’s efforts to lower the cost of hydrogen itself.

The water electrolyzer unveiled in March at Denso Fukushima utilizes fuel cell technology from the Mirai.

Cells in the Mirai’s battery, which generates electricity through chemical reactions between oxygen and hydrogen, share 90% of their parts with the equipment for producing hydrogen by electrolyzing water. Such projects show that Toyota is also serious about hydrogen production.

President Yamagata also reported on a project making hydrogen from poultry-derived biogas in Thailand, where the company has set up a demonstration unit jointly developed with Mitsubishi Kakoki, exploring the production of hydrogen for local consumption.

[Hydrogen] Reshaping tanks with an eye on passenger cars

Generally, hydrogen tanks for large commercial vehicles are cylinders around 2 m long with a diameter of about 50 cm, made of carbon fiber or other materials.

As explained at the event, settling on a single standardized tank could cut costs by 25% and speed up the adoption of hydrogen. At the same time, switching from gaseous to liquid hydrogen can reduce the fuel’s volume, freeing up more space for cargo.

Yoshihiko Hamamura, who will serve as the Hydrogen Factory’s Chief Project Leader (Hydrogen Business), recounted how President Koji Sato once asked why hydrogen tanks needed to be round.

“President Sato also has a technical background, so he knows the answer. He knows, and yet he still asked. That’s why I responded in kind, saying, ‘Actually, they don’t need to be round.’”

With that, he unveiled flat and saddle-shaped tanks currently under development. Varied tank shapes could be mounted on existing cars offering designers greater freedom.

Similarly, Toyota is also exploring the development of half-size cells for its next-generation FC system, pioneering potential uses across various vehicle sizes and models.

A message for Toyota’s engineers

With a focus on BEVs and hydrogen, Toyota’s Technical Workshop showcased a wide array of technologies. While seeking to enlighten the media and other stakeholders, the event also held a message for those within the company.

Vice President Nakajima, himself a former engineer, made the following comment.

“For our technical personnel, the experience of presenting their work offers an opportunity to consider how they will each contribute to our stated mission of ‘changing the future of cars.’”

Engineers were able to share the fruits of their research and view them objectively through the eyes of the public, helping them understand customer needs and fueling further research and development.

In this way, Toyota spurs the cycle of technological development that leads to “ever-better cars.”