"Peace of mind" is key to Toyota's battery development concept. What strengths has Toyota cultivated to achieve the aim of this concept? Chief officers leading the effort explain the key points.

On September 7, Toyota Motor Corporation held a briefing for the media, investors, and analysts on its battery development and supply initiatives. The main presenter was Chief Technology Officer (CTO) Masahiko Maeda, head of R&D at Toyota.

Joining Maeda for the Q&A session to help explain Toyota’s battery strategy were Chief Production Officer (CPO) Masamichi Okada, who heads production, Chief Communication Officer (CCO) Jun Nagata, who heads external and public affairs, and Keiji Kaita, who is the president of Toyota’s in-house CN Advanced Engineering Development Center, which is in charge of innovative efficiency improvements in electrified vehicles, development of new batteries, and use of carbon-neutral fuels.

In Europe, there was an announcement earlier this year proposing a ban from 2035 on the sale of new vehicles with internal combustion engines, and in the United States, the Biden administration later announced a target to have battery electric vehicles (BEVs), fuel cell electric vehicles and plug-in hybrid electric vehicles account for half of all new vehicle sales by 2030.

To respond to these regulatory trends and to achieve carbon neutrality, the key lies in the ability to develop and secure competitive batteries as some automakers are planning to build or invest in battery production facilities.

Although Toyota does not stand out in terms of sales of BEVs, it has been quick as an automaker to produce batteries in-house, which it started doing with the introduction of the Prius, the world’s first mass-produced hybrid electric vehicle (HEV) in 1997. What are Toyota’s strengths and roadmap for the future?

Focusing on CTO Maeda’s presentation, Toyota Times introduces Toyota’s battery strategy in terms of both development and supply.

Three HEVs equal one BEV in CO2 reduction effect

Today, I would like to talk about Toyota's development and supply of batteries toward achieving carbon neutrality.

First, using industrial products as an example, carbon neutrality means reducing CO2 emissions to zero throughout the entire life cycle of a product, starting from procurement of raw materials, manufacturing, and transportation to use, recycling, and disposal.

As you all know, the world's concentration of CO2 has been increasing since the Industrial Revolution. There is no time to lose when it comes to reducing, in all aspects, the amount of CO2 emitted by humankind.

In the case of the automotive industry, promoting electrification of vehicles is one of the most effective ways to inch closer to carbon neutrality.

For example, according to our calculations, the CO2 reduction effect of three HEVs is almost equal to that of one BEV.

At the moment, because we can provide HEVs at a comparatively affordable price, in places where the use of renewable energy is not yet abundant at the moment, electrification using HEVs is among the effective ways of reducing CO2 emissions.

On the other hand, Toyota believes that the increased use of zero-emissions vehicles, or ZEVs, such as BEVs, and fuel cell electric vehicles, or FCEVs, is important in regions where renewable energy is abundant.

Furthermore, in some regions such as South America, bioethanol has been put to practical use as a response to CO2 reduction.

As mentioned above, we should focus on how to avoid carbon emissions or on how to reduce them to as close to zero as possible.

Because the options for reducing CO2 emissions depend on the energy situation at hand, Toyota will continue to try various measures to expand the options for achieving carbon neutrality.

With this in mind, Toyota is preparing a full lineup of electrified vehicles. We want to provide sustainable and practical products that reduce CO2 emissions while considering the convenience of our customers in each region.

Batteries for 260,000 BEVs can reduce 20 times more CO2 emissions if used in HEVs

First of all, please allow me to look back on Toyota's electrified vehicle achievements to date.

Since the introduction of the first-generation Prius in 1997, Toyota has also introduced PHEVs, FCEVs, and BEVs, while also improving performance.

Among such, our cumulative sales of HEVs have now reached as many as 18.1 million units. Earlier, I mentioned that the CO2 emissions reduction effect of three HEVs is equivalent to the reduction effect of one BEV, and the 18.1 million HEVs sold to date are equivalent to the CO2 reduction effect of introducing to the market about 5.5 million BEVs.

The volume of batteries for HEVs that we have produced so far is the same as that of the batteries installed on about 260,000 BEVs. In other words, we can say that the batteries needed for 260,000 BEVs have been used to achieve the CO2 emissions reduction effect of 5.5 million BEVs.

In the future, in light of changes in the market, we will also accelerate the introduction of BEVs and PHEVs, leveraging the strengths we have gained through our experience so far. And we will strive to reduce CO2 emissions by increasing the selection of electrified vehicles we offer and having customers in each region choose us so that we can accelerate the dissemination of electrified vehicles.

Toyota’s plans for a full lineup of batteries

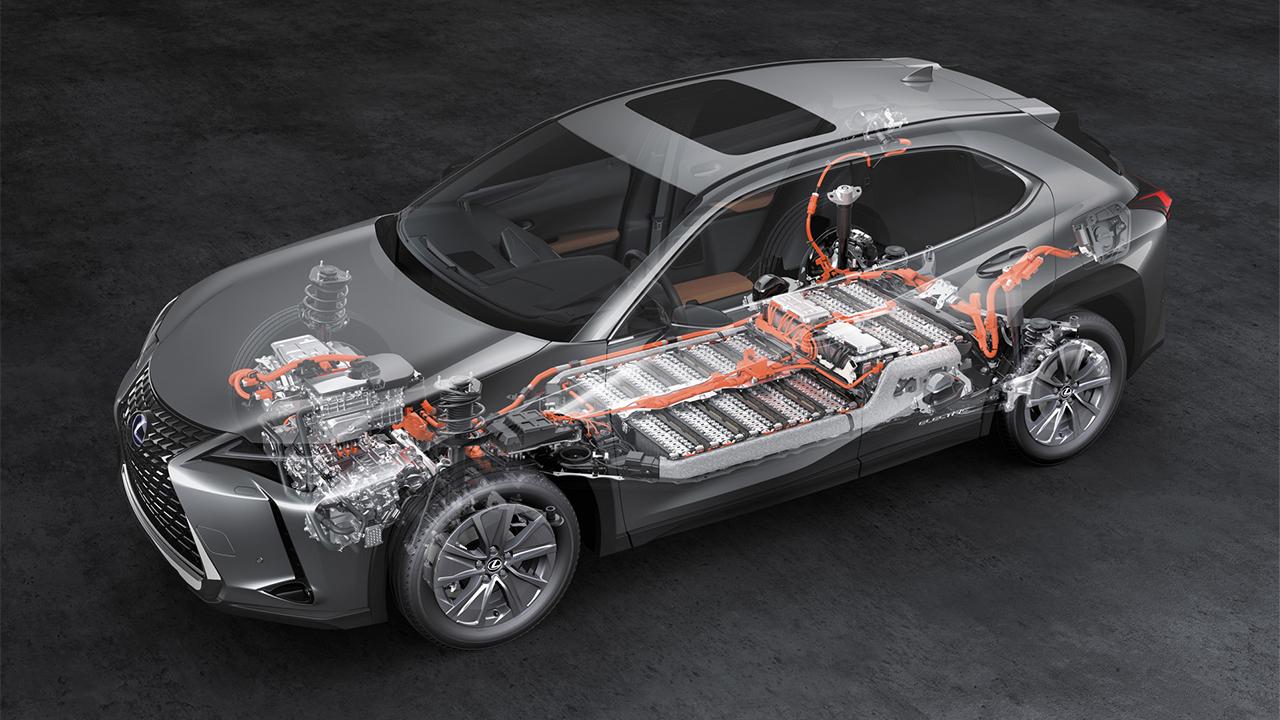

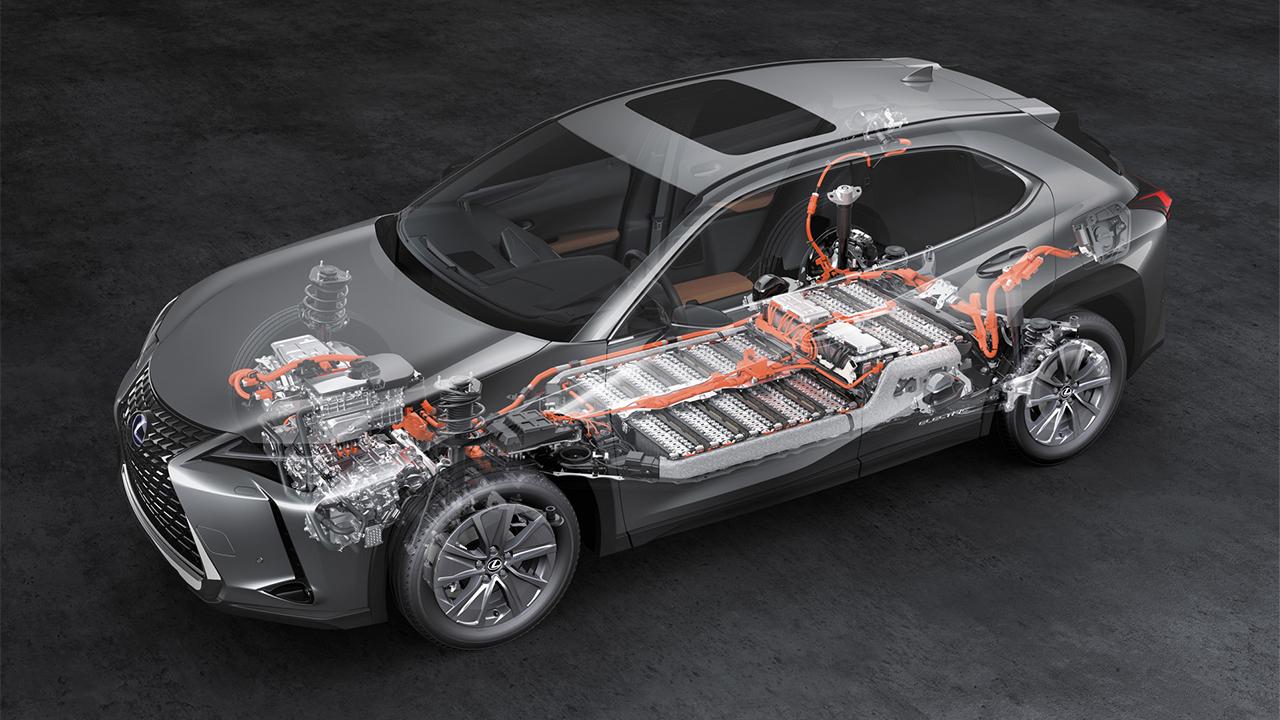

The three core technologies that support this full lineup of electrified vehicles are electric motors, batteries, and power control units.

Today, in this context, regarding batteries, I would like to share with you Toyota's unique approach and the competitive edge that we have developed via the mass production of electrified vehicles.

While promoting a full lineup of electrified vehicles, we have also been developing and manufacturing a full lineup of batteries.

For HEVs, our focus is on power output, or in other words, instantaneous power, while, when it comes to PHEVs and BEVs, our focus is on capacity or what can be called “endurance”.

As batteries for HEVs, we have been continuously evolving nickel-metal hydride batteries and lithium-ion batteries by taking advantage of their respective characteristics.

Our bipolar nickel-metal hydride battery, which was announced this year and is focused on providing instantaneous power, will be used in an increasing number of vehicles. For lithium-ion batteries for PHEVs and BEVs, we have been striving to improve both cost and endurance, and we will continue to improve them as we move forward.

We are developing a further advanced new type of lithium-ion battery for introduction in the second half of the 2020s.