How does Toyota's Purchasing Group engage with suppliers? How many are there, and what efforts are being made to improve relationships? We examine the principles passed down since the company's founding.

Competitiveness and passing on changes in labor costs

Another major topic in recent years has been rising labor costs, including employee wages and how they are passed on through parts prices. Reducing these costs by cutting down the need for workers can also be a competitive advantage for individual companies.

Chief Office Kumakura explained the difficulty of reflecting these factors in purchase prices.

Chief Officer Kumakura

Anyone can see that energy or material costs are rising across society. However, labor costs constitute an area of competitive advantage when making products. A company’s ingenuity is evident in how it squeezes out every second of productivity and sets up processes to produce things in the shortest possible time.

With every percentage point this goes up, the company’s competitiveness falls.

That’s why, in the past, there was a general tendency to instead absorb those rises through improvements. Now, however, amid the growing push to raise wages, we needed to do something.

If we didn’t, we wouldn’t be contributing to the momentum for raising wages across the board. In the past, we called on suppliers to help improve competitiveness, but this time, we sent everyone letters explicitly asking whether they were struggling with labor costs.

In that sense, labor costs differ in character from other expenses. After all, they were one of the focus areas for our day-to-day improvement efforts.

This makes for a very difficult balancing act between passing on labor costs and maintaining competitiveness. Despite those difficulties, we want to spread these efforts across the entire supply chain as a way to overcome worker shortages and boost the industry’s appeal.

When we asked him again about the current challenges, Kumakura responded, “Competitive power and reaching the deeper tiers. I believe that working together with dynamism, down to the deepest tiers of production, ultimately makes our vehicles more competitive.”

Our suppliers

Throughout the interview, Kumakura and Kato’s language left a strong impression, with both repeatedly using words like “mutual trust,” “equal partners,” and “together.”

In general, Toyota’s position as the ordering side is likely to present the carmaker as making unreasonable demands of its suppliers. Such factors may also be hindering the spread of fair pricing.

Perhaps sensing as much, Deputy Chief Officer Kato offered up two anecdotes that evoke the mindset that is important for understanding the relationship between Toyota and its suppliers.

The first featured some wise words shared by a senior colleague.

Deputy Chief Officer Kato

The colleague taught me this expression: “The logic of the strong, the mentality of the weak.” I still have them in my notebook.

From the outside, Toyota may appear to be in a stronger position than our suppliers. As I was taught, the weak want the other side to understand how hard it is to speak up.

This is true not only of the relationship between Toyota’s procurement and our suppliers, but also between superiors and subordinates. We, therefore, do our best to keep our doors open and welcome discussion of any concerns that may arise.

Chief Officer Kumakura

That person gained the insight by stepping outside Toyota.

While larger suppliers may think that way, smaller places don’t always get to that point.

In many cases, the thinking goes: “If that’s what Toyota said, that's what we have to do.” When presented with proper reasoning from the stronger side, they have nothing to say.

That’s what makes the expression so potent: The logic of the strong, the mentality of the weak.

Right now, many suppliers are trying to figure out how to go about raising prices. Asking them to share information and simply passing it on doesn’t get us anywhere.

In this regard, when I returned from Toyota Industries, then-President Toyoda told me to make use of my experience of seeing Toyota from the outside.

Currently, staff from Toyota’s purchasing team are in the process of carefully instructing individual parts manufacturers on how to pass on price rises.

Kato’s second anecdote came from a conversation that took place several years ago between Kumakura and Chairman (at the time, President) Toyoda, ahead of labor-management discussions. How they referred to suppliers speaks volumes about the relationship.

Deputy Chief Officer Kato

The Chairman said something to Mr. Kumakura that really stayed with me.

“At Toyota, we don’t use the word ‘subcontractors,’ do we?”

To which Mr. Kumakura replied, “No, we call them our suppliers.”

This exchange showed that the Chairman feels the same way (about our suppliers).

――Is that something unique to Toyota, or do other carmakers also avoid using “subcontractors”?

Chief Officer Kumakura

I wonder... I dare say not many people call them subcontractors. You only hear it in relation to the Subcontract Act.

(to Deputy Chief Officer Kato) We never used it, did we? Always “our suppliers.”

Deputy Chief Officer Kato

You could add a bit of politeness with “our valued suppliers.”

Chief Officer Kumakura

In the past, I was actually told not to use that. It’s too formal.

Instead, we call them “our suppliers” to convey the sense of closeness.

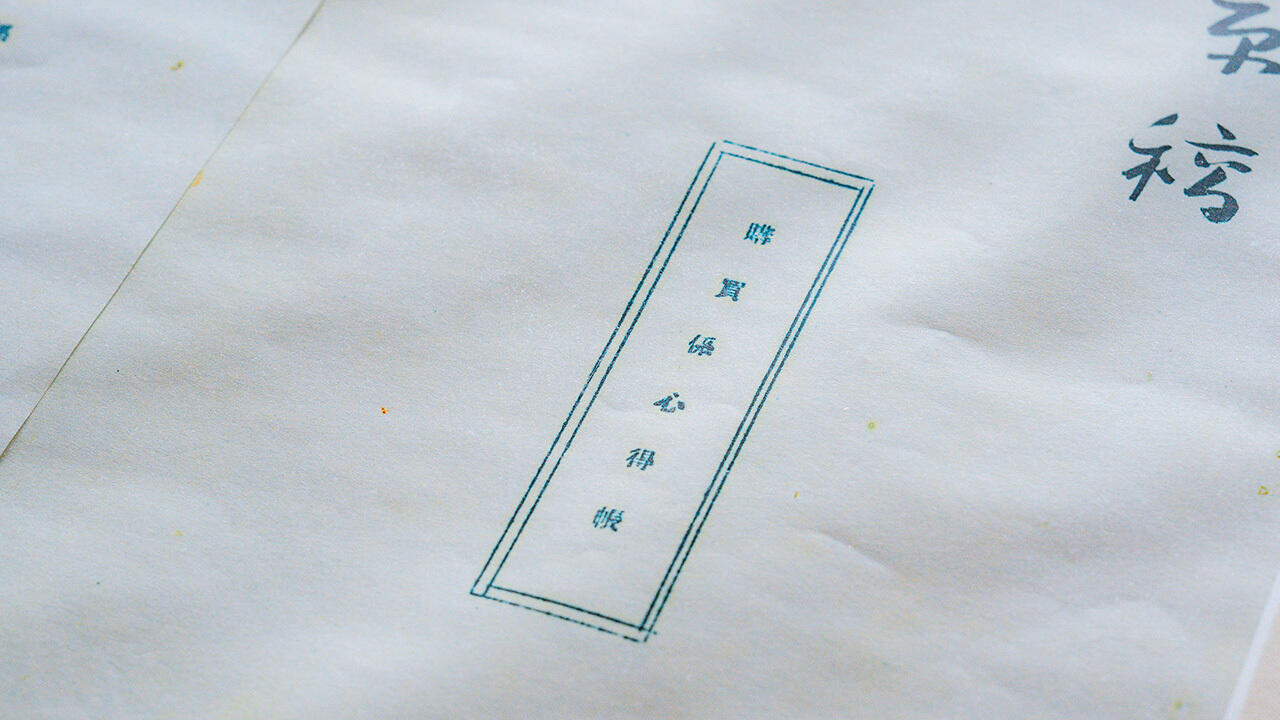

The two anecdotes suggest that the spirit captured by Kiichiro Toyoda in his Purchasing Staff Handbook back in the days of Toyota’s founding continues to be carried forward by Toyota’s procurement professionals.

Next time, we’ll look at some real examples of how Toyota collaborates with suppliers to reduce costs and hear from those working on the frontlines.