Toyota President Koji Sato has been appointed chairman of the Japan Automobile Manufacturers Association (JAMA). He will lead the organization in tackling seven priority challenges.

Communication also gets a revamp

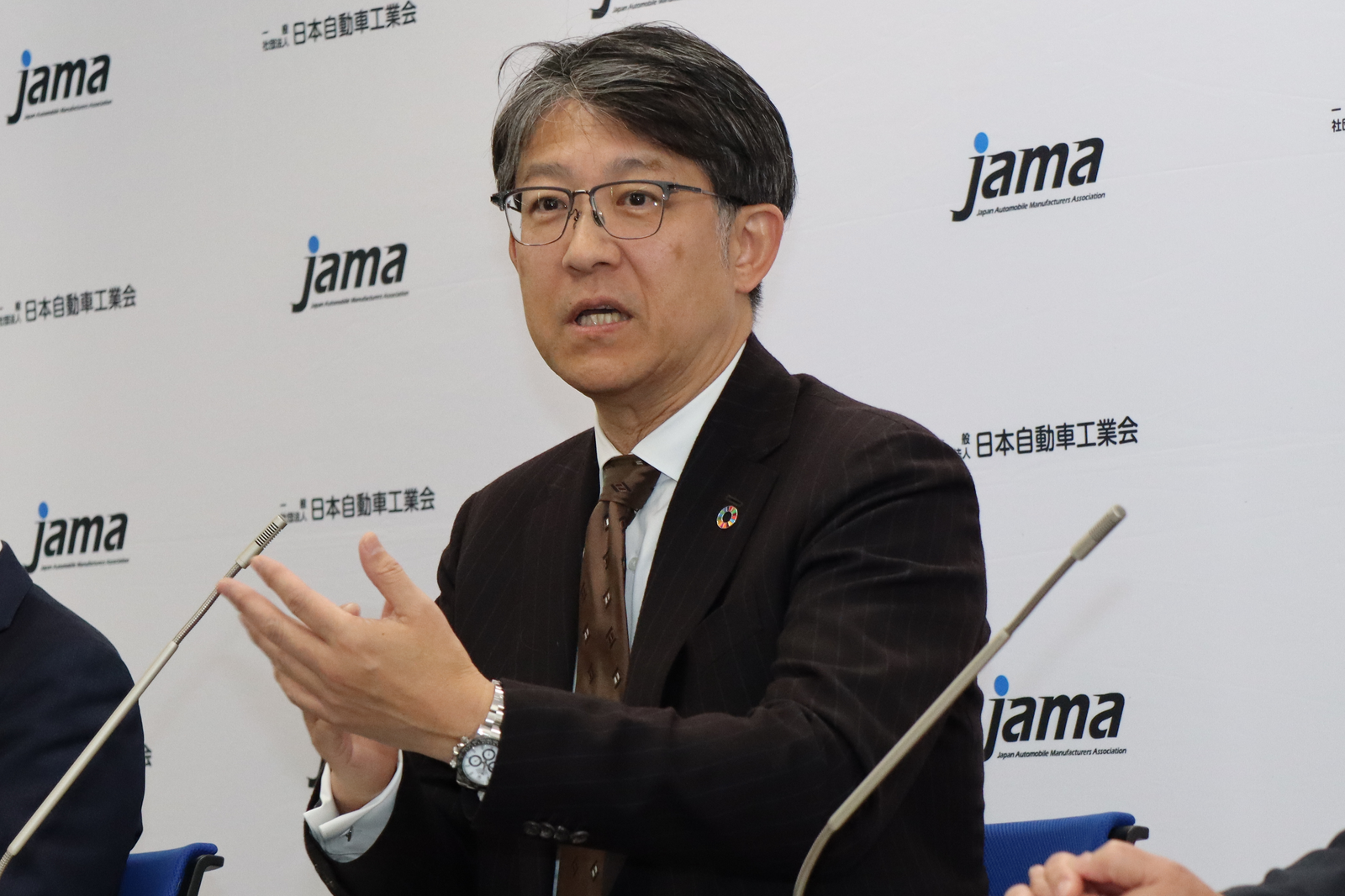

Unlike regular press conferences where the chairman and vice chairmen take the stage, at this media briefing in Tokyo, the JAMA leaders sat eye to eye with reporters.

Chairman Sato explained the aim of this arrangement: “We wish to nurture a deeper, more meaningful relationship with the media, and to that end we will strive to raise the quality of our communication by seeking your input and refining our approach.”

In addition to the regular press conferences, JAMA plans to continue arranging more interactive briefings, with this first session being framed as a trial run.

At the same time, in terms of running the organization, Chairman Sato and his team indicated they will revise the routine board meetings to enable greater speed in tackling various challenges, while also deepening collaboration with overseas automobile manufacturers' associations to respond more effectively to global developments.

During the briefing, there were also moments when the room filled with smiles, revealing that the open, candid relationship fostered by former Chairman Katayama had only deepened.

How serious are you?

From here, we will share the leadership team’s responses to questions from reporters.

Q. The seven challenges you outlined are all massive undertakings, with no endpoints. Are there any particular areas that you would like to prioritize?

Chairman Sato

As you rightly point out, these are all major challenges, making it very difficult to assign priorities.

In terms of pressing issues, I would point to “Securing the stable procurement of critical resources and components” (item 1), as there are numerous areas we need to tackle in the short term to protect our supply chains against immediate risks.

From a long-term BCP (Business Continuity Plan) perspective, we must also discuss making arrangements in areas such as source diversification and stockpiling. Since the situation differs depending on origin, we must determine the specifics one by one, for both the short - and medium- to long-term. This is crucial for item 1.

Regarding tax structures (item 6: Promoting fundamental reform of automobile-related tax systems), discussions are progressing toward the abolition of environmental performance-based reductions. I believe this will provide a tremendous boost to consumption and domestic demand.

At the same time, we remain committed to the three pillars of taxation that JAMA has advocated and are continuing discussions regarding the automobile tax and tonnage tax. In the short term, we need to clarify JAMA’s stance in these areas and carry on the discussions on tax policy.

One area where there are various opinions, including on how to proceed, is “enhancing competitiveness across the entire supply chain” (item 7). I spoke about this briefly during my address at the New Year’s event, and I really do believe that we need to be thinking about international competitiveness.

Our Japanese supply chain is exceptionally broad, deep, and specialized. The individual companies possess remarkably advanced technical capabilities, but I think we need to re-examine whether this truly translates to international competitiveness, and whether it contributes to Japan’s path to success ten years from now.

What changes should we make right now to build a supply chain that turns the multipathway approach into an advantage, while also boosting competitiveness? I think this is a discussion we need to have with JAPIA (Japan Auto Parts Industries Association) as well.

Vice Chairman Toshihiro Mibe (Honda)

I think challenges in item 1 (Securing the stable procurement of critical resources and components) and item 7 (Enhancing competitiveness across the entire supply chain) could pose significant risks depending on how they unfold.

How do we navigate this time, when the rules are changing from day to day, and we face instability and geopolitical risks unlike any we have experienced before? With no clear right answers, I think JAMA serves a tremendously important purpose.

We have entered an era where our old ways of doing things no longer hold true. I believe the role of the JAMA is growing more important than ever. I hope we can continue to exchange information with all of you.

We are prepared for a very tough year ahead. We need to transform society—I feel like that’s the scale of the task at hand.

On the topic of BCP, another question also touched on disaster preparedness, with Chairman Sato noting the need for coordinated, industry-wide response systems. Vice Chairman Mibe indicated a move toward diversifying procurement sources, while also emphasizing the importance of bolstering BCP resilience with involvement from the national government.

Q. In considering the balance between competition and cooperation, I feel that item 7 (Enhancing competitiveness across the entire supply chain) is the hottest topic. How far can you take cooperation?

Vice Chairman Toshihiro Suzuki (Suzuki)

As an example, quite a while ago, we were in talks with another company about jointly developing cars and standardizing our components.

The only thing we managed to standardize was ashtrays.

It is probably a reflection of that time, but we certainly can’t afford to talk like that now. Especially in semiconductors, I think we are now in an era where the only way to be globally competitive is to achieve scale through standardization across the auto industry. In that context, I think we need to work on enabling companies to effectively select whether they opt in or out of specific features.

Vice Chairman Ivan Espinosa (Nissan)

I think for a long time the mindset was “OEMs should not collaborate on components,” but the world is rapidly changing. Unless we change too, we won’t remain competitive.

The decision of whether to compete or collaborate in specific fields may be left up to individual companies, but with the global economy fragmenting into trade blocs, we must cooperate wherever possible to protect ourselves. In doing so, we need to leverage economies of scale and increase our speed and cost competitiveness. This spirit is shared among the leaders here.

Vice Chairman Motofumi Shitara (Yamaha)

Within the supply chain, I believe engines can be regarded as one item that can deliver a major transformation. In motorcycles, for example, we share engines among manufacturers.

The same may be true in four-wheel vehicles between pairs of companies, but if efforts by multiple companies lead to changes in the supply chain, that can be a collaborative area for all Japanese companies to tackle together.

By setting these focus areas, gaining insights, and then feeding those insights back into components, we can create a cycle that is likely to drive change across the supply chain. Those changes won’t happen if each company keeps to itself, and the question becomes whether we can achieve those breakthroughs.

Vice Chairman Katayama

International competitiveness is an enormous issue. While the pricing of parts by suppliers is one aspect, the competitiveness of the OEMs themselves is also being tested on the global stage. Grappling with this reality creates a tremendous sense of urgency.

Rather than being content with the current situation, we need to move beyond that, first by figuring out what we can do as OEMs, and then what we expect of our suppliers. Given that we have a shared fate with our suppliers, I think we are at the stage where we truly need to engage in serious discussions.

This is a really difficult issue, but if we don’t tackle it, things will get worse for everyone. We are going in with that understanding.

Our mindset in these discussions is “we’re doing this.” We’ve really reached that point—it’s tough, but our only option is to get it done.

How to convey the multipathway message

Q. What changes will be brought about by collaborating with auto manufacturer associations around the world?

Chairman Sato

I think Japan is a leading country in multipathway initiatives.

However, as the global environment continues to shift, in terms of creating areas of cooperation or a shared understanding of what a multipathway approach entails, I feel that we may still have some way to go.

We want to encourage other countries to pursue a multipathway approach, to show them the solutions Japan has to offer, and send the message that, by partnering together, we can speed up progress. We hope to build international momentum to spur widespread adoption of our multipathway strategies.

Vice Chairman Akira Matsunaga (JAMA)

A direction for multipathway efforts was set out at the G7 Summit in Hiroshima, but ahead of that, the various automotive organizations and European G7 nations reached consensus on the importance of a multipathway approach.

Although Japan is the country proposing this approach, we will work together with automobile manufacturer associations in various countries to set the direction. Doing so is effective, and the necessary connections are being forged.

With various countries moving toward a protectionist direction, the idea here is to pursue higher-level cooperation.

Meanwhile, Vice Chairman Suzuki added a comment on the infrastructure challenges at home.

Vice Chairman Suzuki

When I visited a gas station during a trip to Europe, they were selling CNG*, along with charging facilities, and even ethanol fuel.

*Compressed Natural Gas. With low CO2 and nitrogen oxide emissions, CNG is used as an environmentally friendly fuel in buses, trucks, and other natural gas vehicles.

Seeing that made me think about the situation in Japan. Although JAMA is certainly touting a multipathway approach, we haven’t followed through to that extent.

With all of this in mind, while it is important that we convey the multipathway message to the world, we also need to communicate how to pursue a multipathway, multi-energy strategy for Japan, and keep discussing what we can achieve through cross-industry collaboration.

The heart of Japanese monozukuri

Q. How will you enhance Japanese talent and elevate the human capabilities that are the strength of Japanese monozukuri?

Chairman Sato

At the heart of Japanese monozukuri are people.

The skills of our people continue to safeguard Japan’s manufacturing industry, particularly the safety and quality of automobiles. This is something we absolutely must not lose.

Even as Japanese cars become higher value-added products, their foundation remains safety and quality.

I believe this is Japan’s strength and path to success, made possible by the continued cultivation of talent as an intangible asset.

“At the heart of Japanese monozukuri are people…something we absolutely must not lose.” Powerful words.

In addition to rewarding the hard work of peers across the auto industry, Chairman Sato also vowed to focus efforts on bringing new colleagues on board.

His team is charting a path to success through the power of people, the source of Japan’s international competitiveness.