English, Chinese, Spanish, German... at least eight different languages could be heard as Toyota employees from 64 overseas business entities gathered to share their knowledge. Toyota Times took a peek inside this globe-spanning company event.

Day 2: Sharing a world of knowledge at the Motomachi Plant

On the second day, the group was split up across seven production plants in the Toyota City area. The morning featured QC case presentations, followed by an afternoon of genba visits and kaizen exchange sessions. Participants were divided up based on the plants they wished to visit.

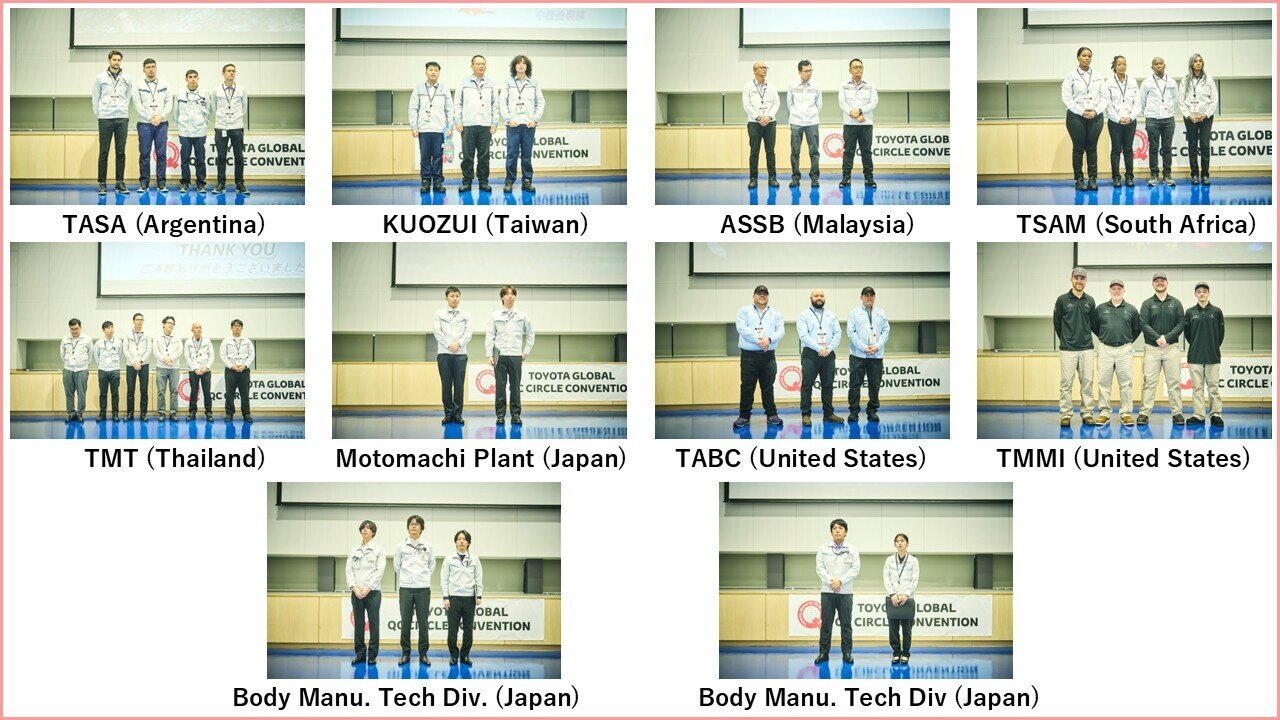

The TMMI team headed to the Motomachi Plant, which hosted QC circles from ten different business entities.

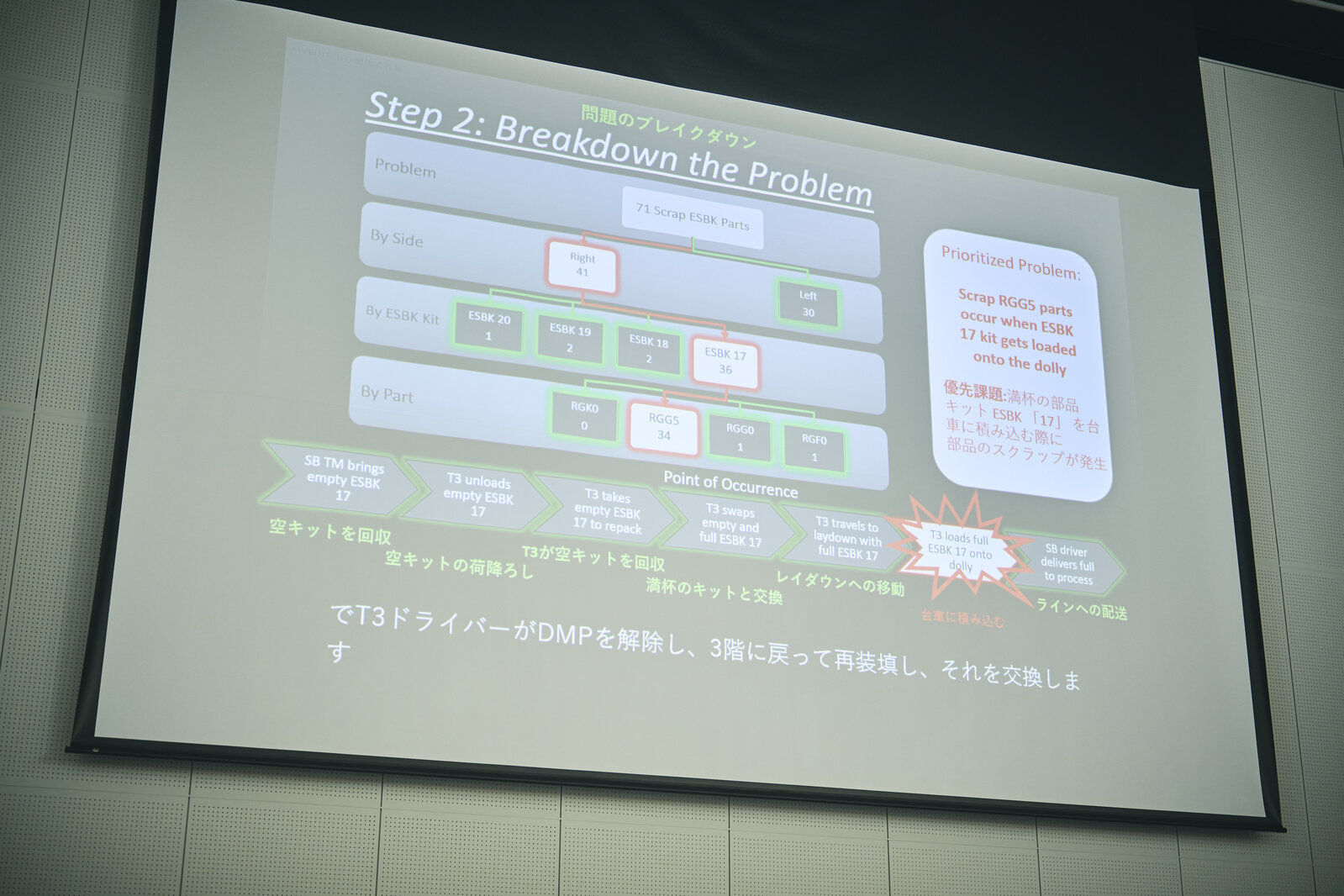

TMMI’s presentation focused on “solving the issue of parts falling and being damaged when kits are transported.”

Constantly questioning “why,” the team probed the root causes and found that the method of securing parts was inadequate.

Borrowing ideas from a supplier’s approach, they prototyped gates for securing components. TMMI’s team explained the process of incremental genba improvements that cut the number of dropped parts by 97%.

To prevent parts from falling, gates needed to be 16 inches (approx. 41 centimeters) larger. The team shared how they corrected the dimensions, along with plans for standardization and adoption by other departments (referred to as yokoten, from the Japanese).

Among the other presentations, team TASA from Argentina showed how they addressed the problem of frequent line stoppages in the final vehicle painting process. To solve the problem, they had to deal with the fact that outside temperatures and humidity in Argentina exceeded equipment standards.

Meanwhile, TMC’s Body Manufacturing Engineering Division presented improvements to the task of modifying main body transports, which previously required working outside of regular hours. Revising the process and harnessing multiple digital tools achieved remarkable results, slashing the number of days requiring holiday work per project from 18 days to just one.

Both Brennon and Spencer from TMMI agreed that “this presentation stood out the most.”

Brennon

It was really interesting to see how other teams break down problems and flesh out their ideas in the genba. In many ways, they were similar to us, but I was impressed by the level of detail in their analysis.

For the afternoon genba visits, the TMMI team joined a tour of the Motomachi Plant’s Body Maintenance Section. They listened intently and asked questions as staff described solutions to logistics-related challenges that were similar to those they face.

Spencer

We thought our plant was big, but this facility eclipses us in both scale and capabilities. The plant’s cleanliness and organization are also incredible.

Despite the Motomachi Plant’s storied past, Spencer says he was deeply impressed by the way it continues to be updated as technology evolves.

The importance of Toyota’s global QC circles

The recent convention was planned and coordinated by Toyota Motor Corporation’s TQM Promotion Division. General Manager Junichi Kobayashi explained its significance.

Junichi Kobayashi, General Manager, TQM Promotion Div.

The main purpose of QC circles is personnel development. While the kaizen itself is important, what matters even more is creating improvements from a desire to make things easier for colleagues by addressing their problems. Through this process, members and leaders grow. Likewise, the QC Circle Convention is not a contest to see whose improvements are best, but an opportunity to learn from each other.

This year’s Toyota Global QC Circle Convention was the event’s 36th edition, following a year off in 2024. As part of wider efforts to strengthen Toyota’s foundations, the organizers decided to pause, take stock, and identify a new direction.

Junichi Kobayashi

In the past, all members gathered in the head office’s administrative building hall and gave presentations simultaneously in separate booths. The format was largely presentation-driven, which gave the impression of limited interaction between sites and a lack of genba perspective. In addition, Japan was positioned as the main driver, with overseas teams participating alongside it. This time, however, Japan has been positioned as just one of the business entities, enabling teams from Japan and overseas to engage with one another on an equal footing.

The decision to split day two across seven separate facilities, with their cooperation, was also a new undertaking.

Junichi Kobayashi

We asked the genba staff to take center stage, while our TQM Promotion Division moved into a supporting role.

LC500 and 1970 Celica LB 1600GT displayed in front of the Motomachi Welfare Center just for this occasion. Inside stood a Lexus LFA, with engine revving demonstrations held during break times. Each plant found its own way to put on a special welcome.

“The event is not the point,” adds Jun Nagashima of the TQM Promotion Division.

Jun Nagashima, TQM Promotion Div.

What matters is how well the lessons learned here are sustained after people return to their respective regions, and whether they contribute to improving QC activities and teamwork. The reward for us is to visit years later and have someone say, “These efforts started because of what we learned in Japan.”

In the past, when initiatives such as the QC circles and Creative Idea Suggestion System stagnated, the company observed a drop in teamwork and problem-solving skills. As Kobayashi emphasized repeatedly, this experience shows the importance of continuing these activities.

What we learned from our Toyota family

At the convention’s closing ceremony, members from each entity shared their reflections on the past two days.

“Chief Officer Miyamoto’s words at the opening ceremony on day one— that monozukuri is about developing people, and QC circle activities are part of our DNA—really stuck with us,” commented a representative from South Africa’s TSAM.

Afterwards, the Motomachi Plant members posed for a group photo before boarding the bus and heading to an informal get-together. It was here that Toyota Times bid them farewell.

Before doing so, we asked the TMMI members, “What does Toyota mean to you?”

Mark

What is Toyota to me? That is hard to express in a few words. Toyota has given me and my family a wonderful life. Not only do I get to drive a Toyota, but every day I can go to work and put the principles of "mendomi" * into practice. As an instructor, I’m able to pass those teachings on to others, and I hope they will carry them forward.

*”Mendomi” is a term used throughout Toyota worldwide, referring to the practice of employees caring for one another as if they were family.

Scott

I love Toyota, I’ve been a fan for a very long time. Before this, I worked in construction for 30 years, but the pandemic brought an end to that, and I joined Toyota.

It was a big change for me, but coming to Toyota and learning the philosophy, I felt that the company really prioritizes our growth as individuals, employees, and team members. That meant a great deal to me, and it’s the reason I love working at Toyota.

Brennon and Spencer looked at each other and gave the same response:

“Toyota is family.”

Spencer

Toyota is like a second family to me. The company has supported me ever since I joined. There are many programs that offer both emotional and financial support. I look forward to going to work every day, and I am very content to have a stable workplace and wonderful team members.

Brennon

People often say that you can’t be friends with your coworkers, but I disagree. When Spencer joined, we immediately hit it off and hung out that very weekend. And now here we are, having a great time in Japan together.

Many people join straight out of high school, and while some might not be used to the atmosphere of Japanese culture, everyone treats each other like family.

Thanks to Toyota, I was able to build a home for my family. Toyota has given a lot to me and my family. I am grateful for the many opportunities I have received. I hope we can continue growing together.

These two days were a striking reminder of the way Toyota members around the world care for each other and approach their daily work with genuine commitment, driven by a shared conviction.

The seeds sown through grassroots activities will, over time, take firm root five or ten years down the line and bloom into distinctive flowers unique to each country.