Reduce, reuse, recycle. Under those watchwords, materials that slip through the cracks can still get a new lease on life--even when they look a little odd!

Every second counts

Fujiwara, Assistant Manager, Innovative Development & DX Dept., Technical Development & Prototype Div.

When you make an ID cardholder from leather offcuts, you produce secondary scraps and snippets. To utilize these, we created small bookmarks. We’re striving toward the goal of using 100% of the material in the future.

Nakamura

In all honesty, we don’t know how many years it will take us to reach zero waste. But one thing I can say for sure: every minute and every second that we stop trying, more gets discarded. Above all, we have to keep going.

Reducing waste through upcycling also cuts CO₂ emissions and disposal costs. Yuta Nakanishi, head of the New Business Planning Division, explains.

Yuta Nakanishi, Chief Officer, New Business Planning Div.

These types of initiatives are meaningless as a one-off. The key lies in figuring out how to nurture this project, which has significant social benefits in terms of cutting CO₂ emissions and waste, into a sustainable business.

I’ve encouraged the team to also set KPIs unrelated to profits, such as the tons of CO₂ and waste saved through this initiative, to ensure we’re contributing to society.

More and more Toyota colleagues have gotten behind these efforts. The General Administration & Human Resources Group has committed to using the ID cardholders for its staff as “a storytelling tool for discussing carbon neutrality.” At the same time, fans outside Toyota are also growing, thanks in part to online sales.

Fujiwara

If we don’t make good products, they won’t get used and will just end up being thrown away as trash again. Since we couldn’t ask for more in terms of functional materials, we’re eager to develop products that people will want to use forever.

Open-minded monozukuri

To craft appealing products, the team has increasingly sought out new partners, including creators outside Toyota. The flower vases and wine holders made from that brain-like purging compound we saw earlier were ideas born out of a workshop with students.

Shinobu Takagi, Project Manager, Business Development Dept., New Business Planning Div.

Two things surprised me when we collaborated with students. One was the difference in how we saw things. What we regarded as waste became “cute” or “cool” in their eyes.

The second was the difference in ideas. As carmakers, we didn’t even think of turning the purging compound into something like a flower vase or wine holder.

We also spoke to those on the ground in Toyota’s plants.

Ryu Uchiki, Shimoyama Plant Fuel Cell Manufacturing Div.

As someone involved in car manufacturing, I felt a sense of guilt about the waste we produce. Being able to reduce that waste makes me really happy.

According to Uchiki, around 20 kg of purging compound is generated every day, or some 400 kg per month. Until now, this was incinerated by industrial waste contractors.

The skills of Toyota’s craftspeople are also harnessed to achieve sophisticated designs.

Kota Yasuma, Shimoyama Plant Fuel Cell Manufacturing Div.

The purging compound was difficult to handle because it would crack and deform, but I was able to overcome that by drawing on my past experience working with various nylon materials.

I enjoy crafting something that, unlike the parts I usually make, will be directly seen and held by customers.

Contributing to the community

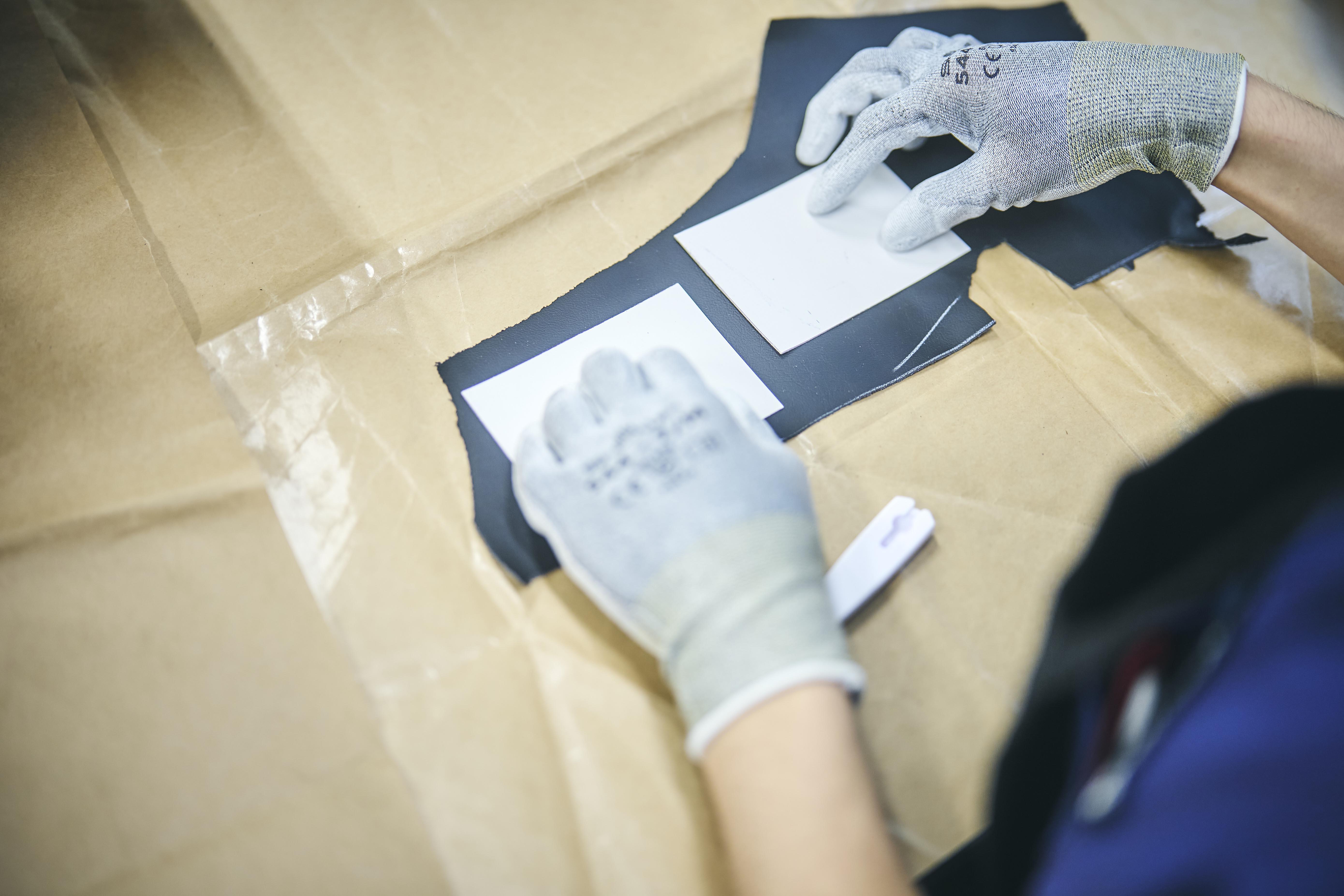

The task of sorting seat leather offcuts is handled by Toyota Loops, a group company in Toyota City, Aichi, that employs people with disability. In this way, upcycling helps to create more of such jobs.

Once sorted, the pieces are taken to a leather workshop in nearby Kasugai City, Aichi, and hand-made into items by veteran craftspeople. The project thereby also supports local industry.

“Unlike bag materials, car leather has a consistent thickness that makes it very easy to sew,” explains one leatherworker. “Being fit for car seats, it is also more than strong enough.”

As the project lead, Nakamura added these final comments.

Nakamura

We are keenly aware that a future where 100% of waste remains in the loop cannot be realized by Toyota alone. We must all work together to collect waste, come up with ideas to create goods, deliver products, and continue to use them mindfully.

Another unique aspect of this project is that we are moving forward together with the help of various people. We are all striving for a future where waste is constantly turned into something ever more wonderful.

While working to expand the range of products, the team is also pursuing tie-ups with apparel brands. For car lovers, this one-of-a-kind Toyota collection is not to be missed!