From "black mass" recycling to methane fermentation, we look at Toyota Chemical Engineering's surprising projects for carbon neutrality. How do the mysterious black substances in the bottles above play a role? Read on to find out.

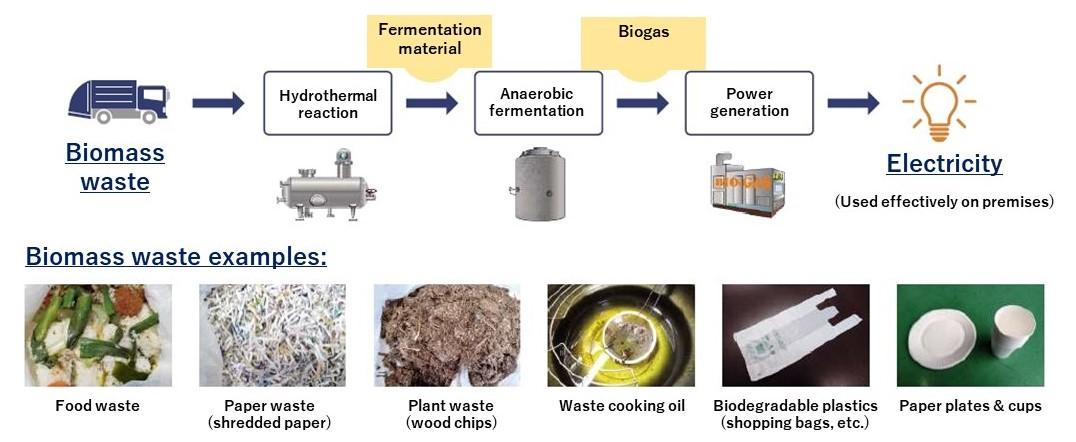

Creating electricity from water and garbage

Toyota Chemical Engineering was established in 1973, a time when pollution from Japan's rapid economic growth was becoming a problem.

The company's roots are in the desire to safely process industrial waste and protect Japan’s environment and local people from pollution. From that desire, the company established a system that not only detoxifies industrial waste but also recycles and recovers factory wastewater for reuse on the premises.

Now, it is developing various techniques for the move toward decarbonization, as well as a method to use the power of water to create electricity from garbage without burning.

We were shown a piece of equipment with a large lid called a “hydrothermal processor.”

What is inside?

A few expired lunch boxes. How can these be used to create electricity? We asked for a demonstration.

From the hopper on top, they put in not only lunch boxes but sawdust, shredded paper, and other garbage. It processes the garbage into a liquid using high-temperature, high-pressure water. To put it simply, it's a massive pressure cooker.

Then, they pump that into a methane fermentation vessel. There, they use the power of microorganisms to ferment it into a gas primarily comprising methane. They use that as a fuel to generate electricity for the plant.

Creating electricity out of household waste without incinerating it is just one of the many technological developments that are going to play a major role in achieving a circular economy.

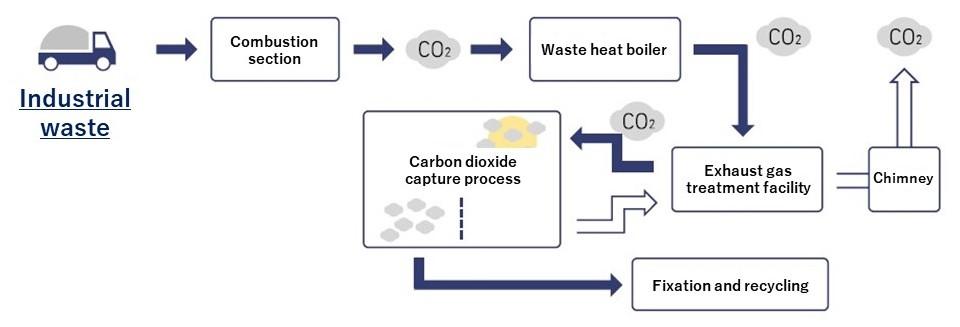

Incineration Without CO2 Emissions

Toyota Chemical Engineering's main business is the proper disposal of industrial waste. In FY2022, the company disposed of 127,432 metric tons of waste, from cinders to plastics, waste oil to medical waste.

Accepting any kind of waste and safely disposing of it demands some incineration.

However, that inevitably results in CO2 emissions. Toyota Chemical Engineering addresses this dilemma that every industrial waste disposal company must face.

Safe disposal and reduced carbon emissions.

To make both a reality, the company is working on capturing the CO2 emitted during incineration.

Incineration waste heat is used to generate electricity equivalent to the annual consumption of approximately 3,000 households, which is then used within the plant.

The company is also capturing CO2, fixing it, and converting it into a resource without releasing it into the atmosphere.

Toyota Chemical Engineering's company-wide dedication to developing these technologies to achieve carbon neutrality and a circular economy is based on the desire to “do something for someone else.”

Yoshihiro Hayashi, President of Toyota Chemical Engineering

Our company's roots are in protecting the environment and local people from pollution, and now our greatest enemy is CO2.

Until now, our most valued process was to detoxify through burning, but going forward, that will not be the case. And in Japan, where resources are scarce, resource recovery is also very important.

I have grandchildren, and I want to leave behind an even better environment for the children of the future. That's why I am continuing to face these challenges with an eye to the future 20 or 30 years from now.

Toyota Chemical Engineering deserves greater attention for these ongoing efforts in confronting urgent social issues through innovative technology.