Toyota has initiated projects to apply its core strength of the Toyota Production System (TPS) more beyond manufacturing areas. This article highlights how TPS leadership views the progress at Toyota's workplaces after the company-wide training program for office staff began last year.

On March 30, 2021, a Toyota internal event to present the progress of TPS-based projects among office positions was held at the Toyota Group’s training facility in Aichi Prefecture. As Toyota Times previously reported, a company-wide TPS training program started last summer for office staff to gain deeper understanding about TPS by practicing it.

Toyota Times reporter Kyonosuke Morita joined the event to find out how TPS has started to be applied beyond manufacturing areas at Toyota in Japan.

First, here is a quick overview of the Toyota Production System (TPS): It is based on Toyota’s management philosophy of “completely eliminating all waste in order to ensure the delivery of good products to customers at reasonable prices, in a timely manner.” The word “customers” refers not only to consumers who actually buy Toyota’s products, but also all those involved in downstream procedures of any work.

“Jidoka (automation with a human touch)” and “Just-in-Time” form the two pillars of TPS. “Jidoka” does not refer to simple automation, but it is automation with a human touch. In other words, it means that equipment is operated in a way in which wisdom of humans are incorporated so that production can be stopped to prevent defects when an abnormality is found. It is the concept of ensuring quality during the production process and eliminating the need for people to be simply watching over machines. On the other hand, the Just-in-Time concept is based on the idea of making only “what is needed, when it is needed, and in the amount needed.”

So what exactly are the “office positions” in question here?

At Toyota in Japan, “office positions” refer to office work and technical work. These are separate from on-site work in plants where cars are actually manufactured. Specifically, it refers to “non-production sites” such as human resources, accounting, corporate communications, procurement, software development, etc.

People working on-site in production have always carefully ascertained the issues in each process in a sustained effort to achieve kaizen. Activities to voluntarily learn and practice TPS have also continued for over 30 years, in an effort to foster people who share a common language. These efforts have been the major driving force behind Toyota’s growth.

TPS is sometimes thought of as only being applicable at plants with production lines. The aim of the company-wide training program that started last summer was to let office staff members realize that TPS is applicable anywhere.The origins of TPS

In August 2020, TPS training program for office staff was launched at all groups and in-house companies with 24 kaizen project themes.

During the presentation held this time, the three representatives, General Administration & Human Resources Group, Business & Sales Unit, and Vehicle Development Center, announced their respective initiatives and progress. The two key persons involved in the TPS training program, Executive Fellow Shigeki Tomoyama, former Chief Officer of the TPS Group, and Kyogo Onoue, the current Chief Officer of the TPS Group, listened intently to the presentations.

Tomoyama was often associated with motorsports, but he was originally a TPS professional with a long career as a “kaizen person” in the Operations Management Development Division responsible for promoting TPS. Before sharing the specific details of the presentations that will be described in the next article, Toyota Times makes clear the two men’s thoughts on the meaning behind the spread of TPS among office staff.

Onoue had the following to say about what prompted this initiative:

Onoue

Of the 70,000 employees at Toyota (in Japan), there are actually around 25,000 office staff. We conducted a survey to know how many of these 25,000 employees had undergone training in TPS, and it was revealed that 18,000 of them had not undergone such education.

Facing this reality, we were concerned about whether TPS can continue as Toyota’s unwavering culture in the future, especially given that some of the office staff would eventually become core senior members who run the company. This prompted the establishment of a new TPS educational system.

People can acquire knowledge on TPS through education, but whether they will be able to make practical use of that knowledge is another matter. So, it was decided that we begin actual kaizen activities.

Onoue reported his intention to begin the TPS training program to upper management, to which President Akio Toyoda said that he would give the first lecture himself (Toyota Times reported on this lecture as shared in the beginning).

His view on TPS, which was also mentioned during management discussions held between company management and employee representatives in spring this year, was something Akio asked the new kaizen members to keep in mind during the kick-off event.

“TPS originates from a desire to make people’s work easier.”

This apparently became the driving force behind kaizen members.

Tomoyama

President Toyoda has a major influence in promoting TPS. He himself has a deep understanding of TPS, and he is probably the only top management capable of putting it into practice, when looking at company leaders around the world. I’ve been at Toyota for 40 years, and apart from the period before, I’ve never seen any other president in the past who devoted oneself so much to this initiative. He may in fact be the first to do so since Toyota’s founder, Kiichiro Toyoda. As such, I think President Toyoda’s presence has provided powerful support to TPS leaders, sub-leaders and other kaizen members.

President Toyoda gave a lecture at the first kick-off event. During his speech, he asked, “What’s the purpose of implementing TPS?” To which most of the leaders replied that they “wanted to further streamline their own operations.”

Upon hearing this, President Toyoda replied, “That’s not right. You implement TPS to make someone else’s work easier.” It was an eye-opening experience to be told the story of how his father and founder, Sakichi Toyoda, developed a power loom to make his mother’s job easier.

Onoue also says that the president’s words helped to promote TPS among office staff as a common language. In fact, likewise, the “common language” or the philosophy of Toyota has also been TPS since its foundation.

Tomoyama

Actually implementing TPS led to supervisors, managers and all other members below that level, and even temporary workers sharing common values.

Until then, each workplace had its own vertical hierarchy, but TPS made everyone realize that perhaps there was something wrong with their workplace, or their work was an inconvenience to others. TPS provides a shared sense of value spanning different workplaces and levels of management, allowing people to realize the potential for making great progress in kaizen, which until then had been difficult to achieve.

The reason why TPS is now being applied to office staff

Tomoyama says the concept of TPS that includes “Just-in-Time” and “Jidoka” is a universal concept in that promoting its spread at the workplaces of office staff will bolster Toyota’s competitiveness.

Tomoyama

In 2019, President Toyoda declared that Toyota will transform from a car manufacturer into a mobility company. The company’s competitors are everywhere, and not just limited to other manufacturers in the industry, so I believe it is required to strengthen our competitiveness through shortening the lead time in all processes, not only in production but also administration, sales and the services field. TPS is one of the most powerful assets for Toyota to survive the battle in the future.

Also, contributing to society by making use of TPS’ advantages that Toyota has built up over the years through monozukuri-I believe this will be an important social mission entrusted to Toyota.

In transforming into a mobility company, the importance of software is ever increasing as Toyota has adopted the idea of “software first” in its development. According to Tomoyama, TPS will offer advantages even in the non-manufacturing process of software development.

Tomoyama

The development of software too involves various processes, such as planning, designing, programming, and testing. It is to set quality standards for every process and build quality, so bottlenecks can be eliminated from every process to shorten lead time. This is where the application of TPS can lead to differentiation from other companies in Toyota’s development of software.

People’s lives depend on cars, and they are products designed to transport people physically. They require everything from tires to suspensions and powertrains. There will always be a need for hardware, but on the other hand, a major part of the control of cars is shifting to software.

That’s why software and hardware must be developed in synchrony, and their quality must be improved. Improving the quality of hardware is something we already do at factories, but there is also a need to improve the quality of software while shortening lead time.

That said, it is no easy task. There are many challenges to practically apply TPS in office work. The keyword Tomoyama referred to as something critical there was “the ability to think through something when conducting kaizen.”

Tomoyama

I suppose issues became apparent after the initiative was actually launched, and the kaizen members probably faced considerable difficulty being caught in the middle between members at the worksite and us supervisors.

I, too, actually had so much difficulty when engaging in TPS at the Operations Management Development Division that I was almost unable to sleep every night. So, I told the members in advance that “you too would probably become so anxious that you will lose sleep over it, but it also means that the “capability to think through” is honed in your brain and heart. So, don’t worry even if thinking too much sometimes bothers your good sleep.”

To continue facing problems right before you in striving to make someone’s work easier requires a lot of effort. The members who gave presentations this time also claimed they had to think really hard. But even in the face of such difficulties, they say they were able to make progress in kaizen thanks to their colleagues.

Tomoyama too, apparently advised them to work closely with their colleagues in thinking things over. What is important in forming ties with colleagues is to take action and lead by showing an example. You act first to make someone’s job easier, and when others see the results, they will follow suit. It triggers a virtuous cycle.

Onoue spoke about the difficulty of TPS from a different perspective.

Onoue

People don’t think their work is wasteful or something to be eliminated. If anything, many of the people at our company are really diligent, so they devote themselves wholeheartedly to the jobs they have been assigned.

Morita

I can understand that people don’t appreciate having their work disapproved. If anything, they want to be appreciated for it. But the role of TPS is to review this.

Onoue

In a way, kaizen is about disapproval of the status quo. “Make your work better than it is now” is one way of saying it, but it could sound as, “The work you are doing now is not good, so it needs to be fixed.” So, a careful approach is necessary when implementing kaizen.

One example is to say, “Wow, you’ve done it really well. Can you do this next then?” I think positive reinforcement is important too.

Allowing visualization of the work

Onoue described actual examples of kaizen among office staff even before the implementing of this initiative.

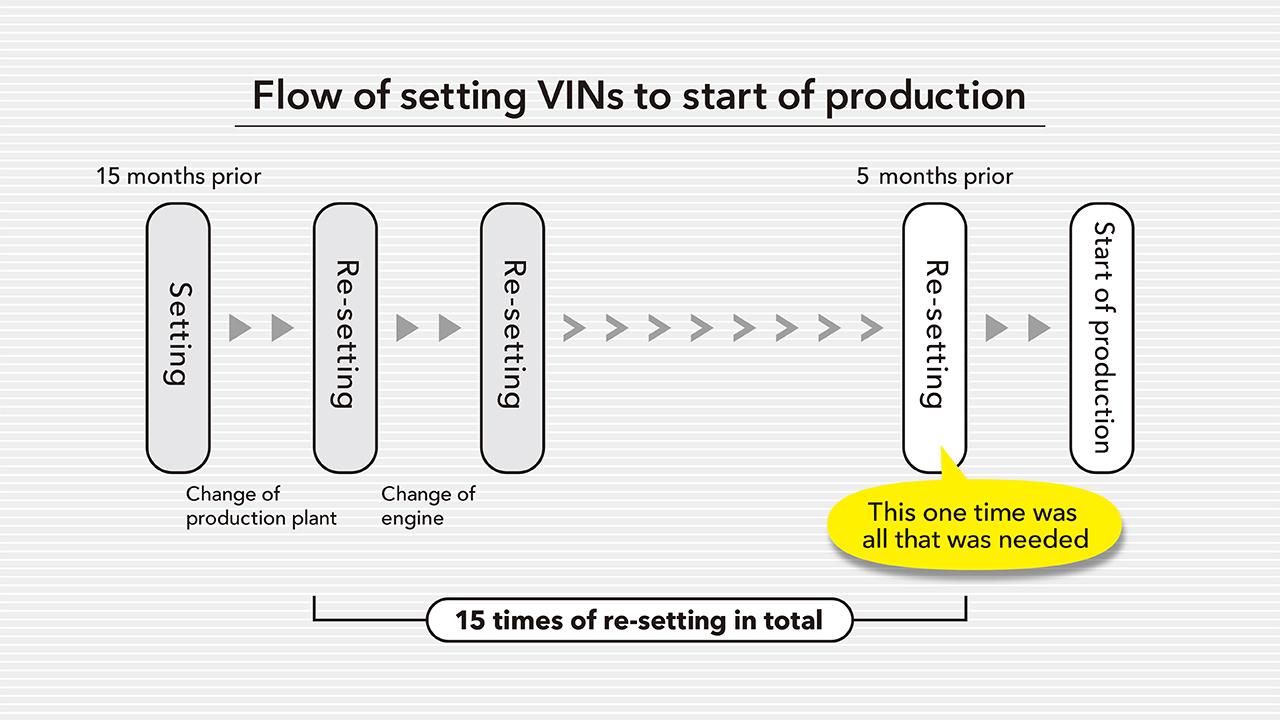

The first example was of a case in a certain engineering department. The department is in charge of allocating VINs (vehicle identification numbers). These numbers are so important that a slight error in stamping these VINs onto the frame may lead to the entire vehicle being scrapped. For this reason, the team started work early to ensure peace of mind, which became a regular process over the years of many members checking, many times.

Before kaizen, the allocation of VINs began 15 months before the production of new cars, but new VINs had to be allocated every time changes were made in plants or to the engine model. This resulted in the re-allocation of VINs 15 times.

The final VINs were allocated five months before production began. In other words, the work started too early. It resulted in a waste of time doing unnecessary work. But the reason they did not realize such a simple problem from the start was because people sometimes lose sight of their true intentions when they continue something for a long time. Realizing this type of waste is the first step in implementing TPS.

Another example was a case in the settling of accounts. During quarterly settlements carried out every three months by the Accounting Division it was taken for granted that employees would work late into the night.

Then measures were implemented for kaizen. The work carried out by all 56 employees involved in settling the accounts was visualized. All questions were listed to clarify “what each was doing,” “what the after processes were” and “why the work was necessary.” And they went to the people in charge of downstream processes to hear how they see each work. It turned out that 10% of documents they were receiving every time were actually not being used.

Why was so much time being wasted on such work? It was because of a problem that arose 10 years ago, and they began preparing the extra documents just in case, and this had continued. But they had apparently not used them once since then.

They actually stopped preparing the documents after that, but it caused absolutely no problems. Eliminating this kind of waste one at a time, apparently resulted in a 30% reduction in the workload within the Accounting Division one year later.

Starting with this activity, TPS activities spread to tax reporting, cost planning, fund management and renewing fire insurance contracts in many workplaces in the headquarters. With the help of the coach from Operations Management Development Division, the employees, from newcomers to experienced employees who play a key role at the workplace, learned the essence of TPS and practiced kaizen by identifying waste themselves, while imitating other member’s work. The entire workplace has developed a culture of making improvements in accordance with the TPS value standards.

Onoue

The time saved through kaizen allows people to engage in other work. It allowed them to do truly meaningful work, but I believe there is still more that can be done by office staff.

First, by using the “materials and information flow diagram”, the role of TPS is to visualize all operations, and ask if each work is really necessary. Making sure your work is done properly eliminates the need for rework in after processes. This makes your own work, as well as the work of people involved in after processes easier, and it also shortens lead time.

Truly meaningful work is known as “value-added work” at Toyota. Employees have to examine their work to determine whether it boosts added value. The aim of TPS is to try and get all employees to do as much meaningful work as possible.

“After kaizen is the state of before kaizen”

Tomoyama and Onoue then reflected on the TPS training program.

Tomoyama

Our method was to first ask people to prepare materials and information flow diagrams after dividing their work into different processes, based on the concept that all work consists of processes. Getting people to prepare the diagrams will allow people to identify the issues and countermeasures. This in turn will enable supervisors and leaders to take a bird’s-eye view of the work based on a shared understanding.

Implementing TPS was a success as a starting point in that it created an environment where a variety of members at the workplace were encouraged to see the problems based on a shared understanding.

I went to a certain division to provide support, and they told me with a look of excitement in their eyes that they were actually able to see their problems and shorten their lead time. It was a very emotional moment for me.

There was another episode that represented Akio’s thinking on TPS.

Tomoyama

I told President Toyoda about this joint presentation, and he said, “Why are you holding a presentation?” What he wanted to convey was that “in this type of presentation event, people praise and thank the presenters for their efforts, and that’s where it ends. They’re meaningless from management viewpoints, and that is not how TPS requires us to be.”

Onoue

There is no end to kaizen as President Toyoda emphasizes that the meaning of the English expression of kaizen is “continuous improvement,” and similarly, Mr. Tomoyama’s motto is, “After kaizen is the state of before kaizen.” I have always used this expression too, and I say, “This is how far we have come. So, we are now in a state of after kaizen, but from today, we enter the state of before kaizen.”

Striving to foster more unconventional people at Toyota

So, how does kaizen spread? Tomoyama has a unique way of expressing his expectations.

Tomoyama

Generally speaking, those who adopt and promote TPS are unconventional people. That’s because TPS promotes the relentless identification of abnormalities, and their immediate rectification.

Normally, people are reluctant to suddenly change their ways, and if they do, they try to take the easy way out that creates less abnormality.

But Toyota is so competitive because the company has so many unconventional people. What’s more, this is not the kind of thing that can be achieved overnight.

In that sense, those who have taken part in this TPS training program are becoming “unconventional people.” If this small group of people could foster more unconventional people, it will bolster Toyota’s strengths.

“Unconventional people” here refers to those who “have an affinity for change” or “adapt to changes.” Onoue says that a virtuous cycle will be created where kaizen leads to kaizen, and that becomes the standard.

Onoue

Once you start kaizen, you can never stop.

Taiichi Ono (who helped establish TPS) said, “When you understand that this is how an improvement can be made by implementing kaizen here, you must make that kaizen at all cost.” But once you begin the process of kaizen, it becomes unstoppable. He said when you see the kaizen you made the following day, and you almost feel angry at yourself for implementing such half-hearted measures, you know you have become a fully-fledged kaizen person.

When you implement kaizen, it makes you want to make further kaizen, and this continues. The fostering of this unstoppable spirit of kaizen at not only manufacturing sites, but also among office staff is what will turn Toyota into a truly powerful company.

All three groups who gave presentations this time say they are working on their next kaizen efforts. Their struggles were apparent from their presentations. “Making someone else’s work easier” is no easy feat.

But if more people continue to work that way, anyone can become the “someone else” who benefits from TPS efforts sooner or later. In the end, everyone will be involved in the virtuous cycle. This may be one of the forms of “producing happiness for all” that Toyota is aiming for. TPS should be Toyota’s core strength regardless of the time and workplace-such understanding is becoming more widespread thanks to the company-wide training program.

The next part of this series will describe specific kaizen efforts and discussions made at the Vehicle Development Center as part of this training program.

(Original Japanese edited by Mami Shoji)