Toyota's Kamigo Plant began operating with state-of-the-art facilities and weighty expectations. Today, what is the plant doing to ensure it will still be making engines a decade from now?

“To all those who have made engines up until now, let's continue to make engines!”

This bold pronouncement was made by Chairman Akio Toyoda, aka Morizo, at Tokyo Auto Salon in January 2024.

Coming amid calls for decarbonization that created headwinds for engines, these words struck a chord with many car-lovers.

As the proverbial “home” of Toyota’s engines, what efforts is the Kamigo Plant making to secure its future? For Plant General Manager Tomihisa Saito, the keywords are automation and digitalization with a human touch.

“Progress in full automation and digitalization inevitably changes the way people work. And we need to change. In terms of workplace operations, the focus will shift from manual tasks to automated machines. I imagine the world will look incredibly different in five to ten years.”

Toyota Times visited Kamigo to see how the plant is striving to evolve in order to continue building engines.

Note: Job titles given are accurate as of the time of our interviews in February.

An automated line 18 years in the making

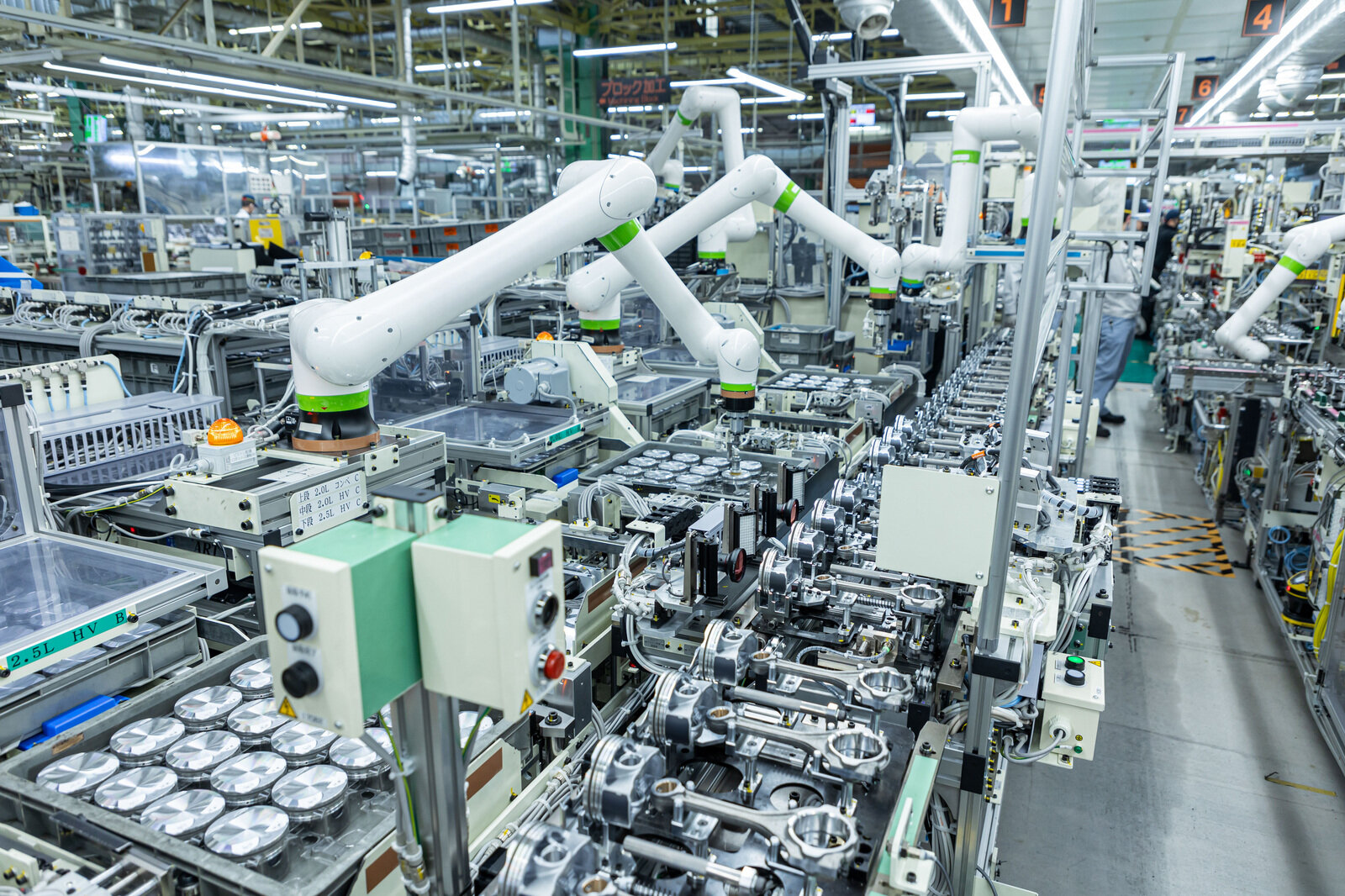

A row of robotic arms grasps parts and fits them together. On this particular line, called the piston subline, the work is now performed entirely by robots.

Engine production can be broadly divided into two assembly processes: the main line, which assembles the engine itself, and sublines that put together the engine’s individual components.

On the piston subline, pistons are attached to the connecting rods that transmit the piston’s up-and-down movement to the crankshaft. These assemblies are then sent off to the main line.

The Kamigo Plant had previously added robots to other sublines as a labor-saving measure, but only for certain processes. In the case of the piston line, which began running with robots in January 2025, the three operators became zero. At present, no other Kamigo line has achieved full automation.

As it happens, efforts to reduce personnel by introducing robots on this line date back to 2008. At the time, however, Toyota was in the middle of expanding its engine plants globally. Lacking skilled maintenance staff overseas, the company had to revert back to manual operations so that expertise from domestic plants could be deployed abroad. In response, employees developed jigs and tools that could double or triple efficiency, even when working by hand, and this assembly line configuration was rolled out around the world.

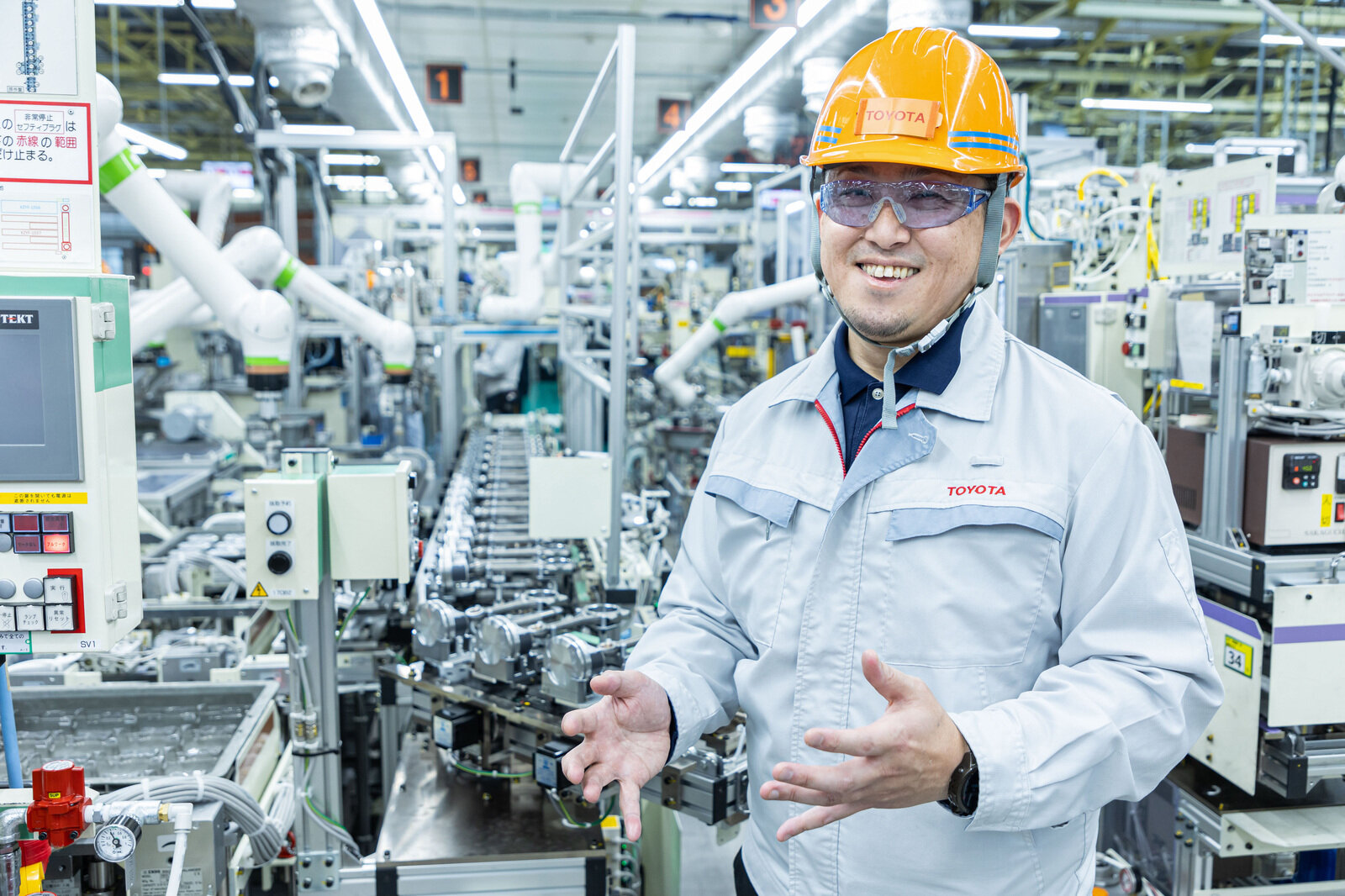

Daisuke Saito, a team leader at the Kamigo Plant/Shimoyama Plant Manufacturing Support Division, says that experience gained in the days when parts were assembled by hand has benefited the automation process.

Team Leader Saito

We need to train robots to have the sense and instincts of a human worker, not just to move in straight lines.

The robot here may look like it is simply grabbing the piston assembly*, but every movement, such as the slight tilt when picking up the part, reflects aspects of how the task is done by hand.

*A unit consisting of multiple parts. This step involves combining components prior to assembling the product into its finished form.

With the piston subline serving as a model, the plant will continue to pursue labor-saving solutions on other lines. As birthrates decline and young people shy away from manufacturing jobs, such undertakings are becoming all the more important.

Consolidating information and expertise

With white walls and rows of screens, at first glance this room seems far removed from the world of production plants. And yet this control center, set up in 2022, is located inside Kamigo’s Machining Plant No.7.

From inside this room, staff monitor the operating conditions of some 300 pieces of equipment on the plant’s processing lines.

Previously, the plant had collected data on power usage and other indicators for each machine, but now their status can be tracked remotely in real time. The resulting data is made visible to help prevent breakdowns and minimize product defects.

The graph below illustrates how potential equipment failures are identified. This graph plots the time when each part was processed (horizontal axis) and the maximum amount of power required to process it (vertical axis). As can be seen, at a certain point, maximum power usage rose sharply.

Upon detecting the irregularity, workers checked the equipment to find a loose nut. In doing so, they prevented a large number of defective parts from being made.

Previously, diagnosing such irregularities and mapping the data visually required specialized skills. At the control center, digitally-savvy younger employees lead the way in data visualization, drawing on the experience of veteran colleagues to service equipment when abnormalities are found, and to pin down the true causes of failures.

Senior Expert Norio Ito of Engine Manufacturing Section No.23 (Kamigo Plant Engine Manufacturing Div.2) shared the following comments.

Senior Expert Ito

Without fundamental knowledge of the equipment, it’s not possible to resolve the problems or determine the true causes—why does the graph look like this?—and then take appropriate measures.

It is our skilled genba veterans who can use the data to improve the shape of the curve. Junior and senior members team up to observe and analyze the equipment on the ground, and work toward a solution.

Kamigo’s control center brings together young and seasoned personnel from various departments, including manufacturing engineering and quality control, so that they can swiftly respond to all kinds of difficulties. The information they collect is consolidated and shared. By having workers of different experience levels jointly tackle problems, the center also contributes to personnel development.

Expert Ryutaro Kawai, who likewise belongs to Engine Manufacturing Section No.23, spoke of the control center’s significance in forging connections.

Expert Ryutaro Kawai

Through this center, we can now connect people from related departments. I think bringing people together here, where everyone can look at the obtained data, speeds up our problem-solving.