Toyota's Plants: Inheritance & Evolution is a series introducing the history and future vision of individual production facilities. This article shines the spotlight on the company's first engine plant.

Standing at the southern tip of Toyota City in Aichi Prefecture, the Kamigo area has a population of around 33,000 residents. It is also home to Toyota’s Kamigo Plant.

After passing through the main gate, visitors are greeted by a banner stretching across the road, reading, “Welcome to Kamigo Plant, home of the engine.”

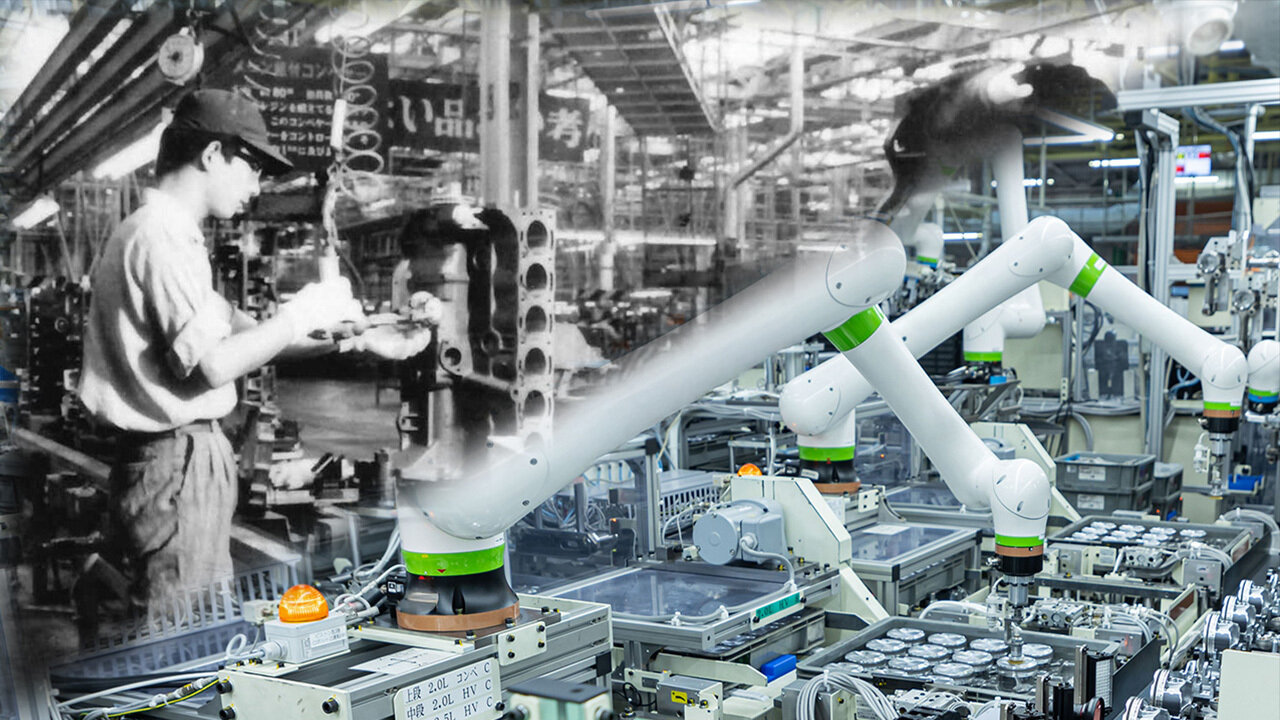

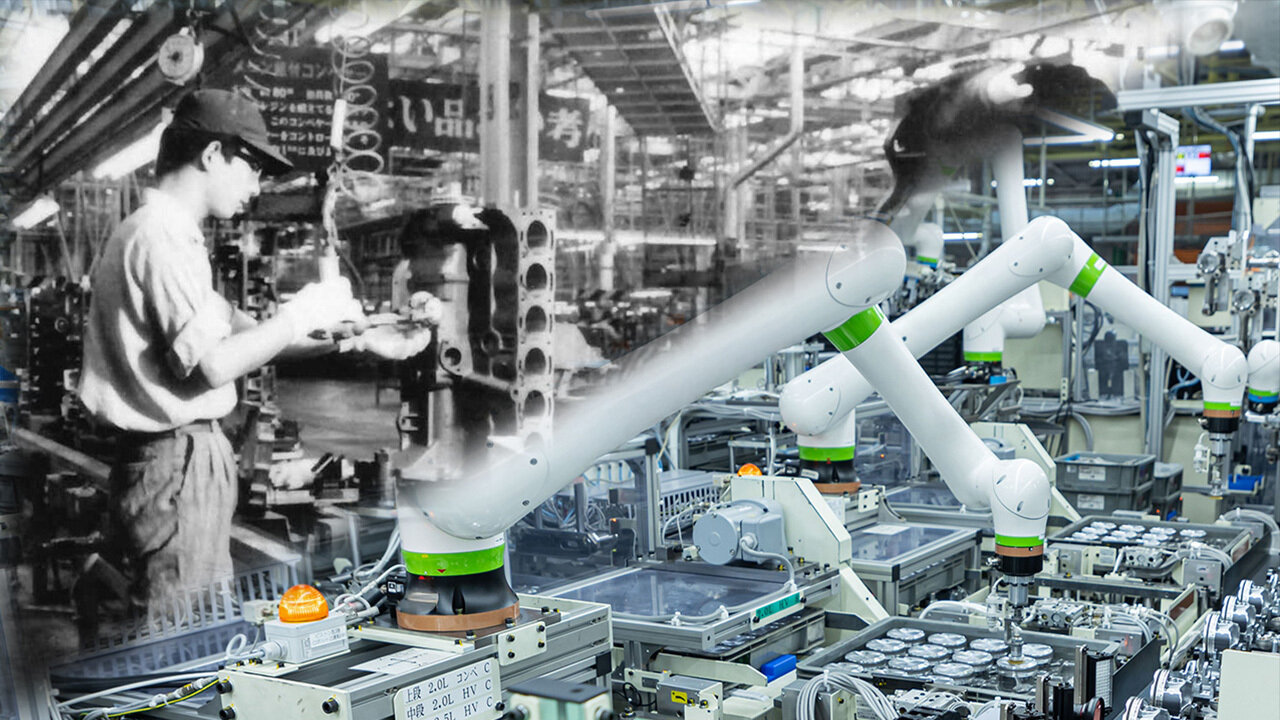

Kamigo began operating in 1965 as a dedicated plant for engine units, a specialization it retains to this day, handling everything from casting and machining to assembly.

These engines are produced on a site spanning 900,000 m2, employing some 3,700 workers.

Starting with the Type M engine used in the second-generation Crown, Kamigo has built engines for models such as the Corolla, HiAce, Prius, and JPN Taxi.

As the plant celebrates its 60th birthday in 2025, what has its journey looked like over the past six decades? And what message does it hold for the future?

Note: Job titles listed are as of the time of our interviews in February.

Japan’s first dedicated engine plant

Operations started with the Koromo Plant, the current Honsha Plant, in 1938, and at Motomachi Plant in 1959, steadily expanding Toyota’s production capacity.

At the time, Japan’s motorization was advancing rapidly, and the liberalization of passenger car imports—set to take effect in 1965— was approaching. Toyota kept strengthening its mass-production capabilities, aiming for 50,000 vehicles per month. As the basic strategy took shape, with the Honsha Plant specializing in trucks and Motomachi focused on passenger vehicles, Toyota decided to build the new Kamigo Plant to exclusively produce engines and transmissions.

The plant’s core concept, set out in 1964, called for “integrated production of engines and transmissions, from casting to machining and assembly,” “the relocation of the Honsha Plant’s block and head casting, and aluminum parts casting from Motomachi,” and “the adoption of the latest equipment and a good working environment, with the aim of halving labor requirements.”

Construction began in October that year, with the first Type M engine coming off the line in September 1965. The plant held a completion ceremony in November, with then-Chairman Taizo Ishida giving an address that was captured by our venerable predecessors, the Toyota Newspaper.

As a plant specializing in engines, we are proud of having state-of-the-art facilities to rival any in the industry, and of pursuing automation through Toyota’s unique production technologies, from raw materials to finished products.

(…)

While harnessing the full potential of this plant, the entire company is committed to continually improving quality and performance, and striving to reduce costs, to fulfill the expectations of our customers.

Toyota Newspaper, Issue 633 (November 13, 1965)

As the speech notes, the Kamigo Plant was furnished with equipment considered groundbreaking at the time, including low-frequency electric melting furnaces*1 for the casting process, and transfer machines*2 deployed across various machining processes.

*1 Electric melting furnaces used for cast iron and aluminum that employ set frequencies. These furnaces could make use of low-cost materials (scraps from stamping, shavings from machining, etc.) and did not require secondary materials such as coke, making them very economical.

*2 Equipment that automatically transfers workpieces through the sequence of processing machines. These machines supported efforts to streamline workpiece transport and contributed to labor savings.

The front page of the Toyota Newspaper for January 1, 1966 features the words “Happy New Year,” accompanied by a photo of Type M engines on their way from Kamigo to Motomachi, illustrating the company’s hopes for its new plant.

When Ohno or Suzumura come calling…

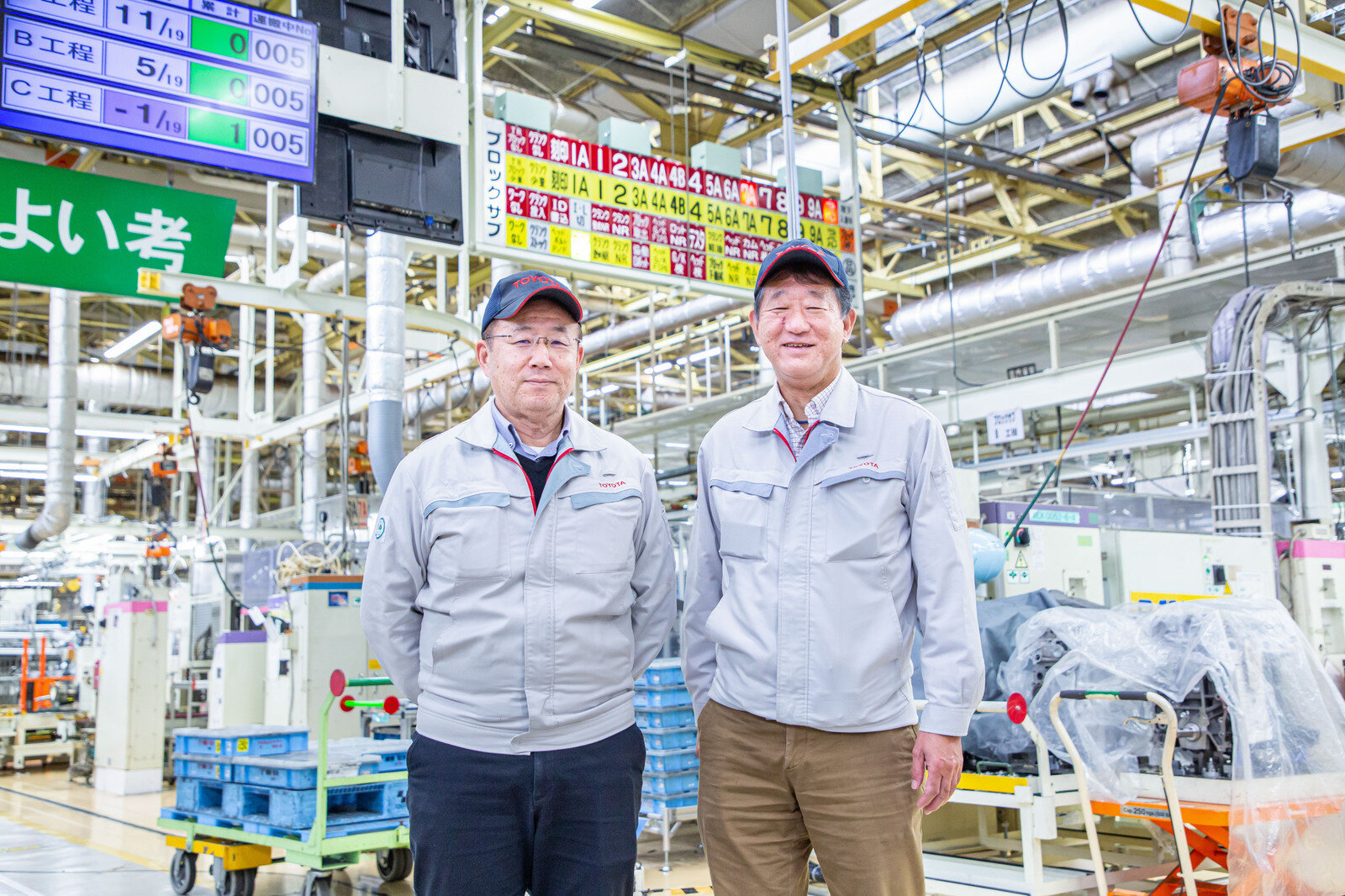

With that, the Kamigo Plant was up and running. On December 1, 1965, Taiichi Ohno—the man who codified the Toyota Production System (TPS)—was appointed as the plant’s general manager.

He served in that role until 1968. A history of Kamigo’s first two decades, created in 1985, describes how Ohno exhorted the plant’s engineers to continue making improvements, stating that “those initial hardships laid the groundwork for the Toyota Production System in today’s foundries, and for Kamigo’s world-renowned engine castings.”

The current general manager, Tomihisa Saito, joined Toyota in 1976 and was assigned to the Administration Division’s Facilities Section (now the Machining Maintenance Section) established by Ohno. Today, Saito oversees both the Kamigo and the Shimoyama plants. He believes that Kamigo’s strength, tracing back to the plant’s beginnings, is its capacity for kaizen.

Plant General Manager Saito

Without the ability to keep improving, there is no growth. This mindset has been passed down through the years.

Following the TPS approach highlights all kinds of issues— “This needs to be improved, this needs to be automated…” We’ve made sure that those who are closest to the genba can immediately make improvements when something comes up.

When Ohno or Kikuo Suzumura (who worked with Ohno to establish TPS) paid a visit, everyone would sharpen up. We were told to just try things out.

It’s okay to fail. Even if we failed, they would say, “Try it a little more like this,” and once things started to take shape they would let it be.

They visited quite often. Each time, I fretted that the machines wouldn’t run properly that day. But the kaizen really did proceed with incredible speed.

Saito says he loves kaizen. Even during our visit, it was striking to see him go out of his way to encourage junior team members. “I especially praise the younger ones when they do it and tell them to keep going. I believe the kaizen culture is more deeply rooted at Kamigo than anywhere else.”

Learning from the real thing

From here, we will take a closer look at the Kamigo Plant’s history and various efforts to pass on technical skills.

Let’s start with the Toyota Production System established by Ohno. Since 2017, an area called “TPS no Sato (Home of TPS)” has been set up within the Kamigo Plant. Although the Honsha Plant also has its TPS Fundamentals Line, the difference here is being able to learn TPS on mass-production and automation lines. With a focus on machining, employees can learn about the concepts that gave rise to systems such as the andon and kanban, through reference materials as well as genba work with actual processes and equipment.

Hiroyuki Tagami, group manager at the Kamigo Plant/Shimoyama Plant Management Division’s Skill Development Department, outlined the basic concept as “a line that serves as hands-on learning experience, spurring improvements and providing insights to develop personnel who can think and implement ideas on their own.”

Since opening, the area has drawn visitors from beyond the Kamigo Plant, including Toyota employees and personnel from around the Toyota Group.

Project Manager Hiroshi Yoshimitsu, who works alongside Tagami in the Skill Development Department, says, “TPS no Sato demonstrates how history has shaped the way things are done today.”

Project Manager Yoshimitsu

The andon has been transformed through the years. If our engineers were to pursue further evolution into something different from the current TV monitors, we would want them to look back over history to see the original purpose, and the aspects that should never be changed. That is our approach to history at TPS no Sato.

The concept here is to allow people to once more unravel things that have become black boxes, so that they can understand them and how they became the facilities we have today.

At the TPS no Sato entrance hangs a banner inscribed with Ohno’s words:

“To see is to believe; to do is to learn.”