A series showcasing Toyota's research in non-automotive fields. This time, Toyota tackles farming.

Akio’s mysterious white lines

Touring the Nabehachi Nousan facility as it underwent improvement, then-President Toyoda remarked that “this is an interesting farm” and offered kaizen suggestions of his own. Among them were the white lines we saw earlier.

In fact, these lines help the unloading process to run more smoothly by making it easier for trucks to stop in the correct position, boosting efficiency. They are a common sight at Toyota’s plants.

The kaizen process has been underway at Nabehachi for more than a decade now, giving employees a greater awareness of potential improvements. When a tractor accident made the news, the workers were the first to suggest wearing helmets.

Though other farmers may snicker at Nabehachi’s helmet-wearing, for the employees working to sustain their families and livelihoods, safety takes precedence over all else.

“Words like ‘waste’ and ‘safety’ now come up naturally in the workplace,” President Yagi remarks happily. Successes lead to future improvements.

Visualizing soil composition

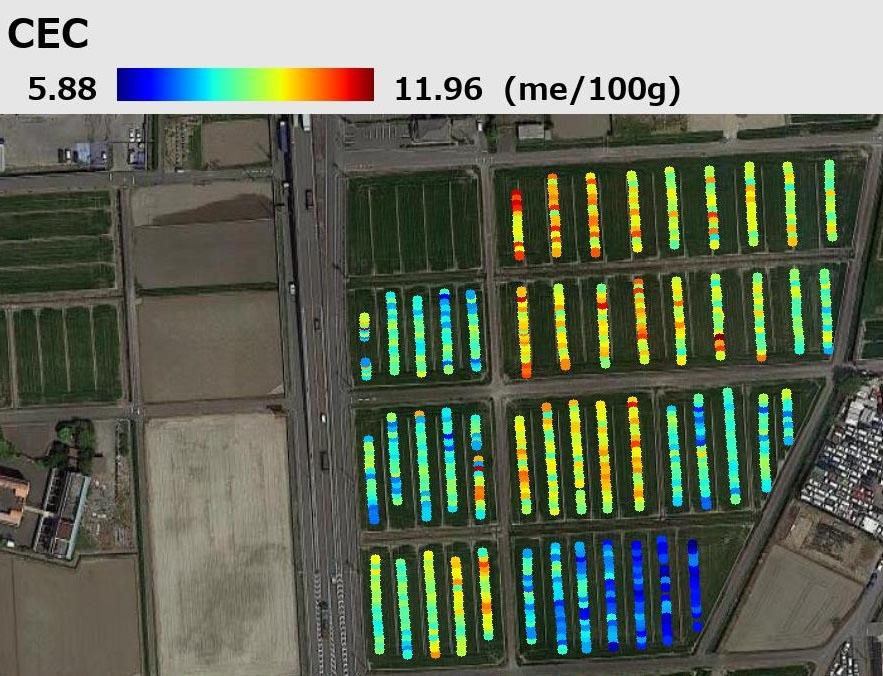

Another initiative has also progressed alongside the TPS-driven genba improvements. This image tells the story:

The colors overlayed on the rice fields are generated by a soil sensor technology currently under development.

Soil is the lifeblood of agriculture. Toyota’s soil sensor can determine the composition of soil by exposing it to light and reading the reflection.

By optimizing fertilizer application based on this soil analysis, developers seek to improve crop yields while also reducing the environmental impacts of fertilizer overuse.

President Yagi’s eyes light up at the prospect of what he sees as a “magical” solution.

Katsuya Shimizu, Project Manager, Soil Sensing Promotion Group, Agriculture & Biotechnology Business Div.

The soil’s ability to absorb fertilizer varies from place to place. Although Yatomi City’s sandy soil is weak in this regard, the remnants of islets and sandbanks boost retention in certain places.

Detailed soil sensing enables us to apply fertilizer only when it is needed and in the right quantity for each location. This reduces materials costs and environmental impact, making operations more sustainable.

These various improvements have also allowed President Yagi to focus on his primary role as a manager.

Yagi

Once I was able to see the bigger picture, I began thinking about why rice is so cheap, and production costs so high.

Even in years when rice prices plummet, convenience stores always sell onigiri at the same price, while farmers struggle. That frustration led me to start our own onigiri shop.

Besides running the onigiri shop, he has also begun selling rice-derived cosmetics online. Nabehachi is winning acclaim as a successful model for agriculture.

Having gone through this process, President Yagi says he was provoked by the words of one Toyota employee who told him that “kaizen is like a living creature—you need to work to keep it alive.”

“What nonsense!” Yagi recalls with a laugh. “Of course, we’ll keep going!”

President Yagi hopes that young people will discover the joy of farming. At Toyota, the services showcased here are expanding beyond rice growers to cover vegetable and livestock farms. In the coming years, this constant pursuit of improvement may give rise to new innovations in agriculture.