The kaizen spirit is part of Toyota's DNA and has its roots in the Creative Idea Suggestion System. We look at the history and intentions behind the long-running initiative, which also serves as a tool for fostering kaizen talent.

How the Creative Idea Suggestion System works

Over its more than 70-year history, the Creative Idea Suggestion System has undergone a series of improvements, yet the steps remain largely the same.

1. Make a habit of noting down problems or troubles encountered in daily work

2. Investigate the causes of the problem and come up with ideas for improvement

3. If unable to get the ball rolling, consult a supervisor

4. Supervisor provides support and advice based on the individual’s progress

5. Implement the improvements, checking results quantitively (and at times qualitatively)

6. Fill out and submit the designated suggestion form

7. Supervisor conducts genchi-genbutsu review to determine reward amount

8. Receive reward

A 2019 revision of the assessment criteria created two score categories: “outcome scores,” which evaluate an improvement’s effectiveness across five areas, and “process scores,” which score the employee for their concept, originality, and effort, from identifying the problem to implementing the improvement. The total across both categories determines the award value.

These values range from the Prize for Suggestion 500 yen to 2,000 yen for Outstanding Prize, 5,000 yen for Excellent Prize, and 10,000 to 200,000 yen for The Best Award. Prizes above 5,000 yen are judged by the department general manager or manager, while those worth 50,000 yen or more are decided by a Creative Idea Committee within each plant or division.

No suggestion too trivial

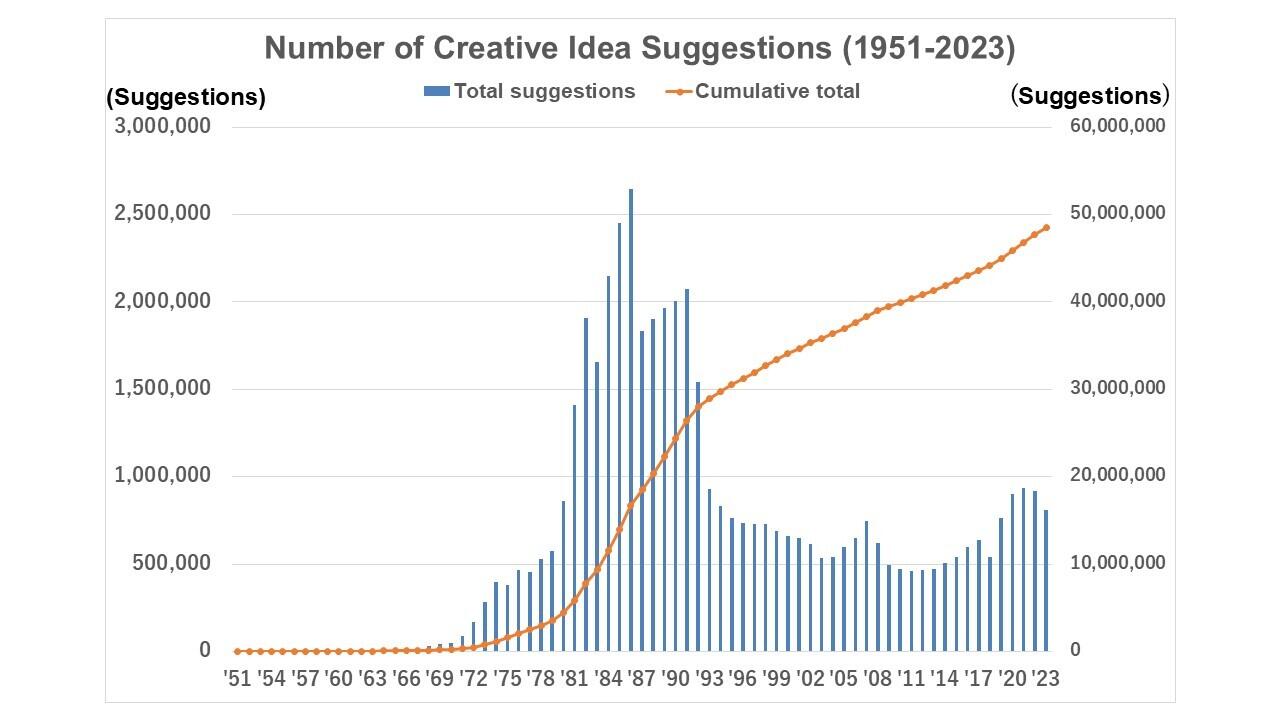

Given its long history, how many suggestions has the Creative Idea System yielded?

The numbers are staggering. In 2023, some 810,000 suggestions were submitted, averaging out to 67,000 per month, or 14.4 per person over the course of the year (based on plant technical staff). As we can assume from these figures, the ideas are mostly small innovations rather than astounding breakthroughs.

What’s important here is the attitude and understanding of the supervisors who receive suggestions.

When you’re young, you can’t make big improvements. But changing the position of a trash can so you don’t have to walk around it is also an improvement. Supervisors need to take such suggestions seriously, too. Otherwise, that person will not make another. I’ve hardly ever said no. Instead, I encourage them—that sounds great! Let’s try it and see what happens!

While receiving a monetary reward is nice, Kawai says that nothing brought greater pleasure than hearing colleagues praise your idea for making their lives easier. “It was exciting to watch the workplace landscape change.”

This excitement and enjoyment spurs further improvements. Such an atmosphere also energizes the workplace, turning the suggestion system into an effective tool for developing personnel.

To this end, and to instill the habit of creativity, the company has also set up a Rookie Award for first- and second-year employees who achieve at least 36 suggestions in a year, a pace of three per month. New Toyota employees, particularly those in the production genba, receive guidance for reaching this goal. In the process, they accumulate experience that sets them up for larger innovations.

How submissions are swayed by changing work environments

Looking at the graph, some readers may question the soaring peaks in the 1980s.

Heading into the bubble economy era, the work environment changed. This was a period of massive transformation, with increasing production volumes, labor shortages, and equipment automation. At the same time, the competition over suggestions was heating up, particularly among plant divisions. Because that competition emphasized quantity over quality, we also changed the nature of the system.

Just as oil shocks in the 1970s led to more energy-saving suggestions, today, a growing number of them are related to carbon neutrality and digitalization. Employees have even made their own apps to streamline work tasks. Clearly, periods of upheaval in the working environment stimulate innovation and make ground-breaking ideas more likely to emerge. Meanwhile, the Creative Idea Suggestion System must also change to keep up with the times.

Sadayuki Yuzawa, Professional Partner, Genba Kaizen Dept., TQM Promotion Div.

These days, fewer jobs have quick answers, particularly in the fields of administration and engineering. What’s more, even when you have an idea, turning it into reality often requires bringing together the skills and ideas of many different people. Moving forward, I think we need to establish a platform for making suggestions along with a framework where those who endorse an idea can share their knowledge and skills to bring it to fruition.

As a first step, the existing digital system is being revamped. Currently, suggestions are evenly split between paper and digital submissions, partly because production site employees cannot freely access computers. Such infrastructure aspects are included in the push for digitalization, which will further encourage the sharing of creative ideas.

Over the past seven decades, the system has racked up an astonishing 50 million suggestions. From the outset, it was intended “not only for the genba,” yet even today, most submissions come from technical staff at plants and other facilities. That said, Toyota’s administrative and engineering personnel also produce a steady stream of unique ideas.

To make ever-better cars, we need everyone to be involved in kaizen and every workplace to be nurturing such individuals.

In upcoming articles in this series, we will shine the spotlight on past ideas that have since become a familiar presence in the workplace.