The liquid hydrogen Corolla took on its second Fuji 24 Hours Race. Despite a long stint in the pits, the car showed remarkable advances. We sum up three key areas of progress.

Upgrade 3: CO2 capture system

Another area of evolution is a revamped CO2 capture system, originally introduced in the final round of last season.

We won’t delve too far into how the system works, but a filter coated in a CO2 adsorbent developed by Kawasaki Heavy Industries (amine) is used to catch carbon from the atmosphere (adsorption phase). Hot air is then passed through to release the CO2 (desorption phase), which is then dissolved into a recovery liquid (capture phase).

At last year’s final race, mechanics manually replaced the adsorption and desorption filters during each pit stop.

This time, the two filters have been combined into one, eliminating the task of replacing them.

Specifically, engineers enlarged the filter’s diameter and made it rotate slowly at two revolutions per minute. While three-quarters of the filter’s surface area is exposed to the air being sucked into the engine, the remaining quarter is fed air heated by the engine oil.

As the filter rotates, sections that have adsorbed CO2 circle around to make contact with the hot air, releasing the CO2. This process is continuously repeated during driving, increasing the CO2 capture rate.

By expanding the filter’s surface area, the new system captures 4 grams of CO2 per lap, double that of the previous arrangement.

Given that even fuel-efficient cars emit around 100 grams of CO2 per kilometer traveled, this is still a drop in the ocean. However, fine-tuning the filter’s adsorption/desorption areas and rotation speed will help make a greater contribution to the environment.

If engines can capture more CO2 with every mile driven, perhaps they will start to shed their infamous reputation.

Peering over the peak

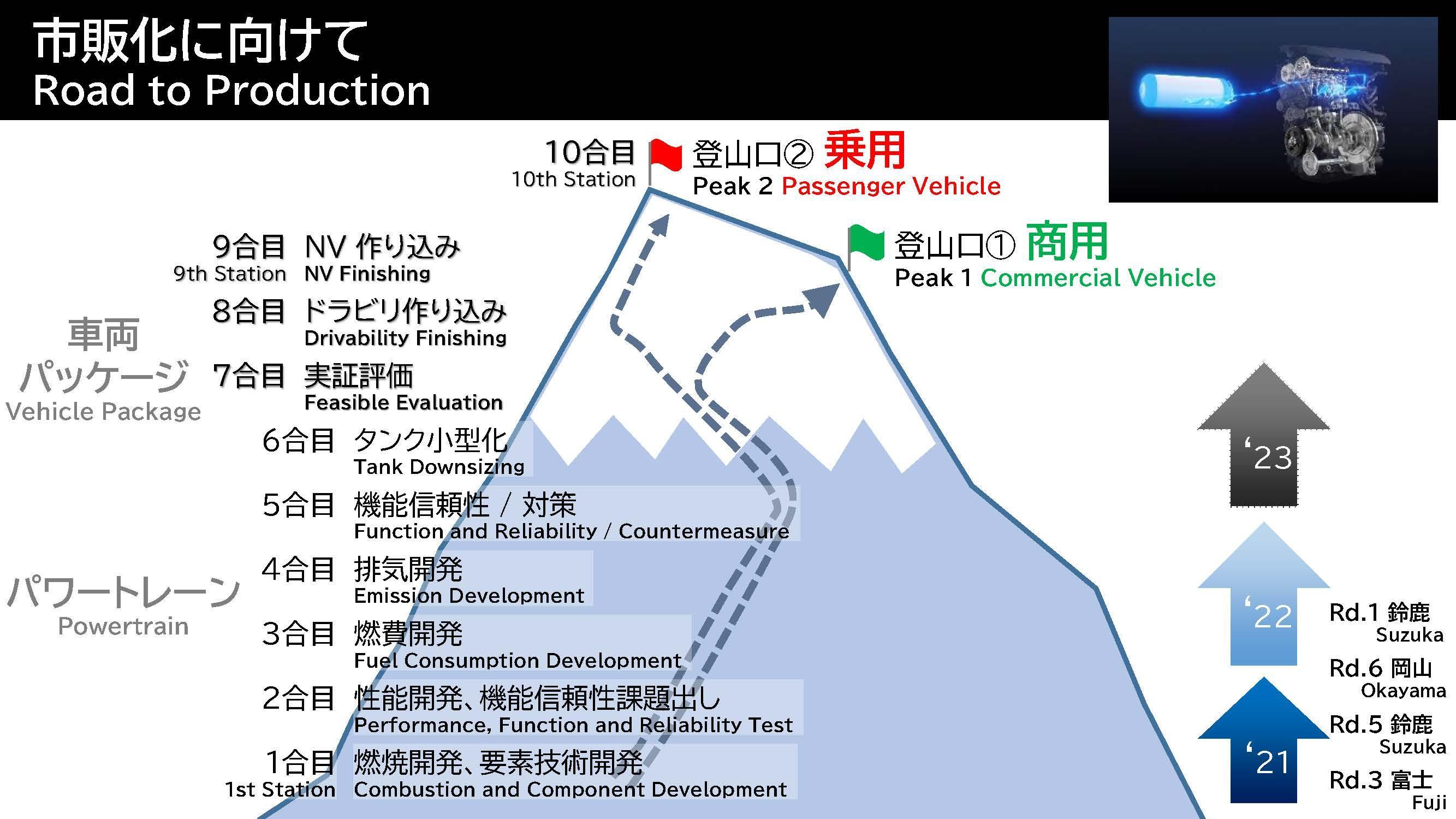

With every bit of progress in hydrogen engine development, the conversation always turns to the same question: where are we along the road to production?

At last year’s final race, Toyota unveiled that it would begin public road testing of a hydrogen-powered HiAce in Australia, saying we are “two-thirds of the way toward commercialization.”

With this season’s remarkable advances, expectations were high for the next progress report. However, President Takahashi was cautious, saying, “Last year we talked about reaching the seventh station, but now it’s hard to tell whether we were really that far along.”

“Until now, we’ve been climbing Mount Hydrogen, but what the 24-hour race keenly brought home is that, in order to make ever-better cars, we need to conquer various other mountains beyond this peak. I think it’s clear that reaching a single summit is not going to deliver great cars to our customers.”

Ascending one mountain has opened up new horizons, revealing the next peak that awaits. As always, the trail gets tougher as it nears the top. Toyota is taking it one step at a time, steadily honing its hydrogen technologies.