Hydrogen engines are two-thirds of the way to production, continuing to evolve through both racing and public road trials.

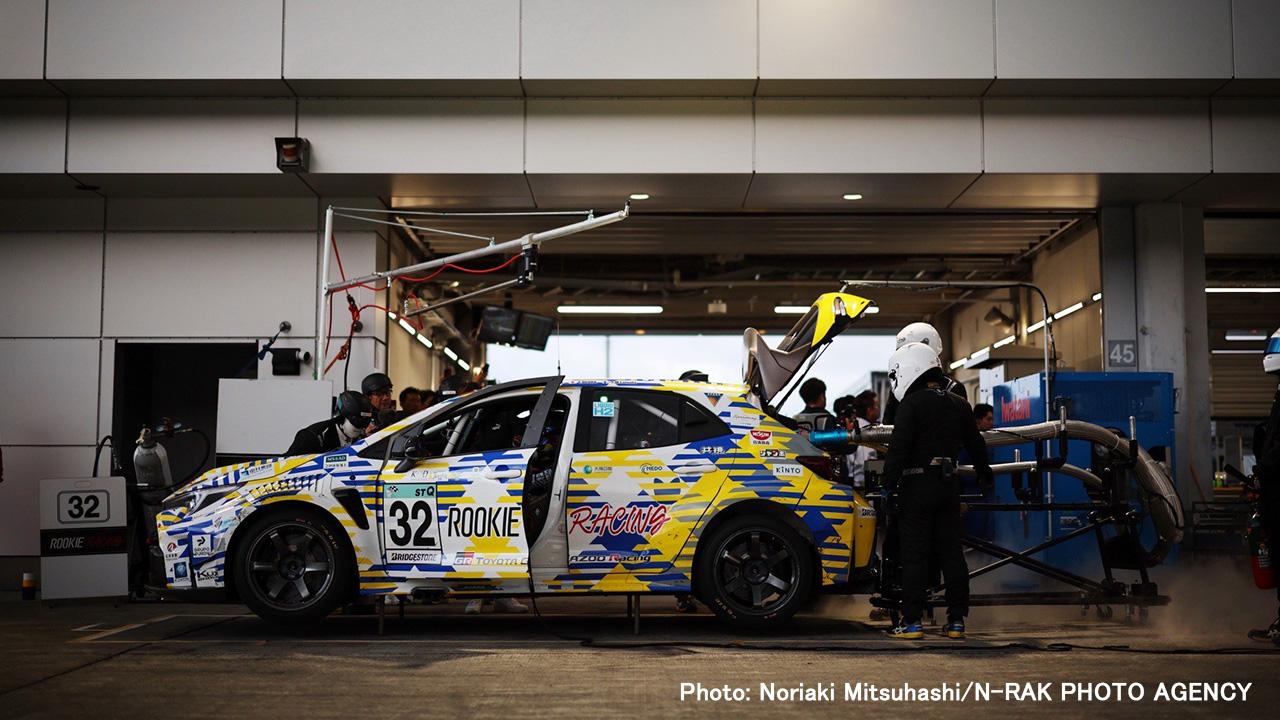

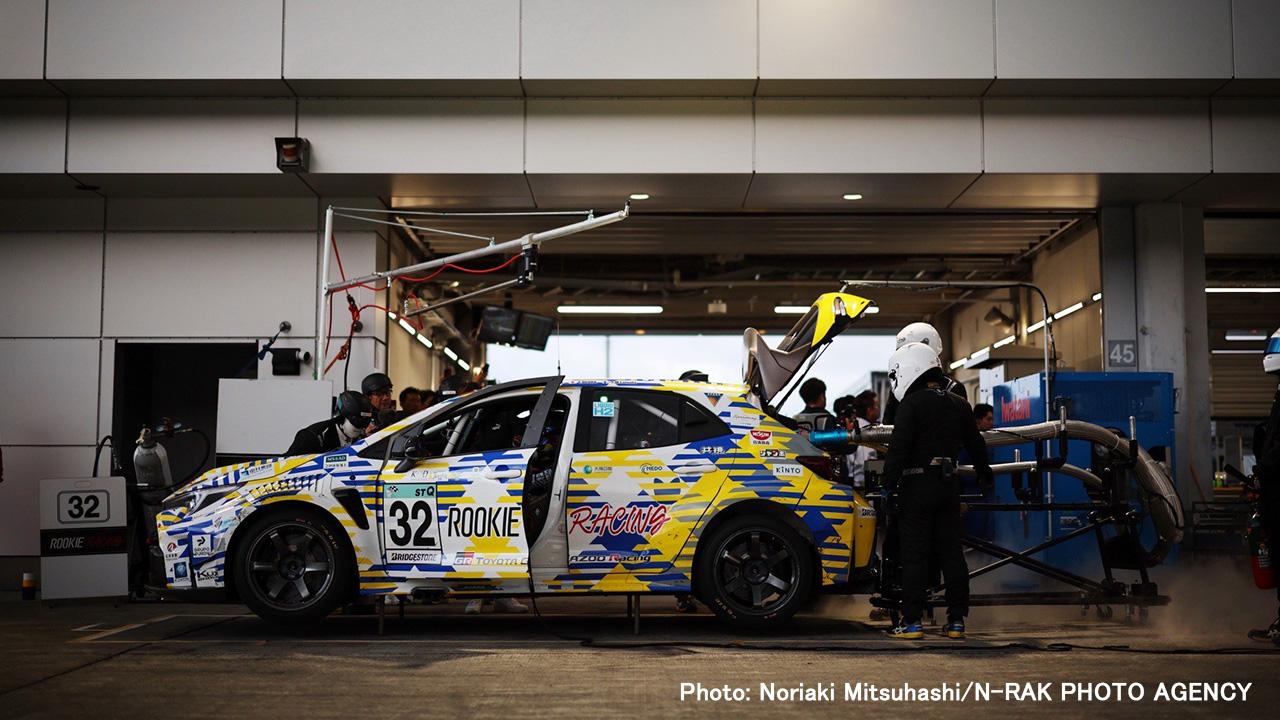

The final round of the 2023 Super Taikyu Series wrapped up on November 12 at Fuji Speedway in Oyama, Shizuoka.

ROOKIE Racing fielded three cars, with the #14 Zhongsheng ROOKIE AMG GT3 finishing third overall to clinch the 2023 series championship.

The other two cars—the #28 ORC ROOKIE GR86 CNF concept running on carbon-neutral fuel and the hydrogen-powered #32 ORC ROOKIE GR Corolla H2 concept—both closed out the season by completing the race.

This year, Super Taikyu again provided the backdrop for Toyota’s efforts to make ever-better cars through motorsports, with each race helping to develop machines and personnel alike.

In particular, the hydrogen engine challenge that Toyota embarked on in 2021 reached a major turning point.

Alongside a new technology that captures carbon dioxide (CO2) as the car runs, the company announced that a gaseous hydrogen-engine HiAce had begun public road trials in Australia.

We bring you an update on the various advances in hydrogen-powered engines, which are now some two-thirds of the way toward commercialization.

Upgrade 1: Carbon capture technology

Since the H2 Corolla entered racing in 2021, hydrogen engines have gained growing recognition as carbon-neutral technology.

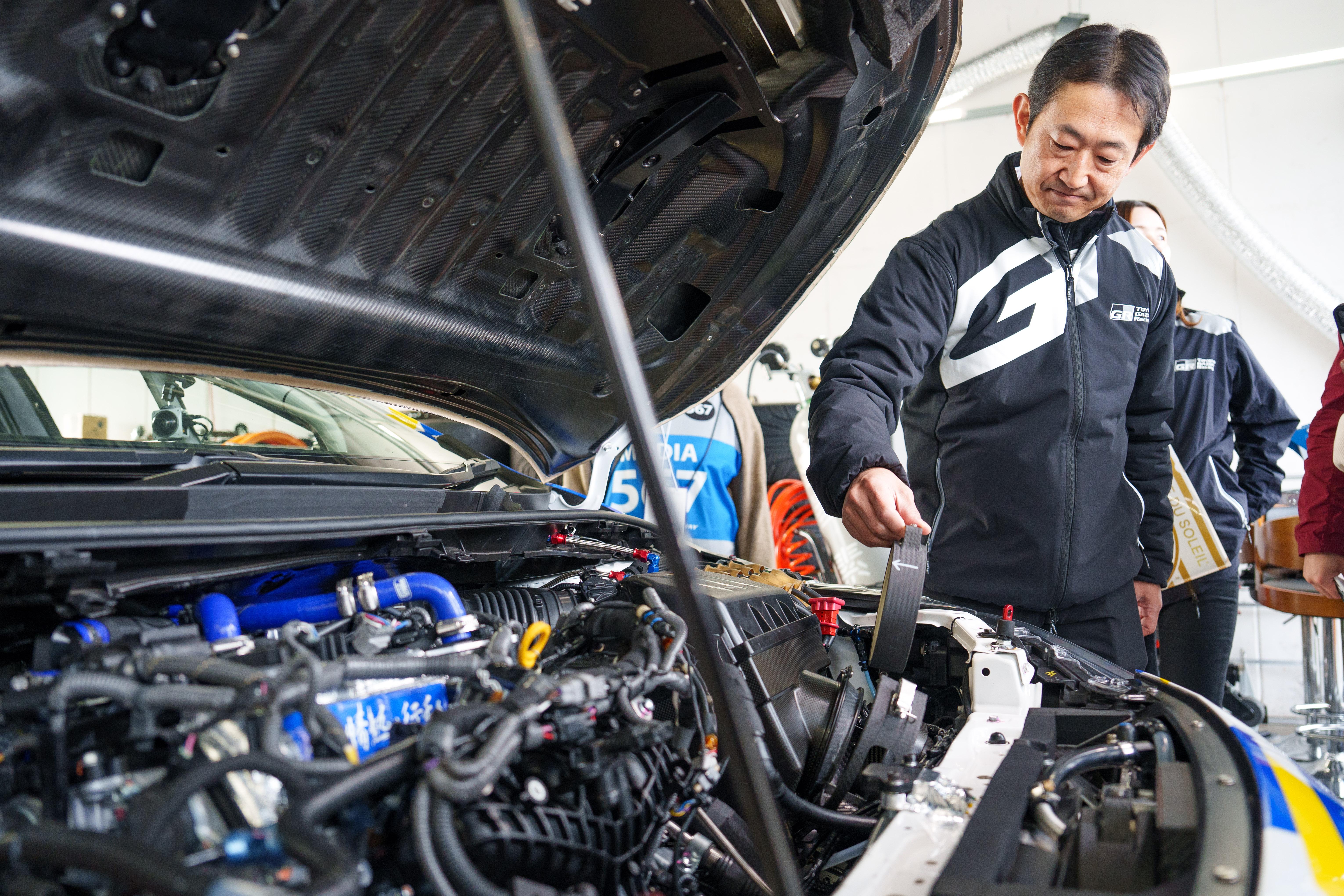

For this race, the team began experimenting with a new technology for capturing CO2 as the car drives.

The secret lies in two filters and a fluid fitted under the hood.

These filters consist of a ceramic catalyst, commonly used in the exhaust pipes of mass-produced vehicles, coated with a CO2 absorbent developed by Kawasaki Heavy Industries.

The first filter is mounted at the inlet to the air cleaner (position 1 in the photo), capturing CO2 from the 60 liters of outside air that is sucked in every second.

The other filter sits at the very front of the engine bay (2 in photo), along the path taken by the engine oil as it circulates and lubricates the engine—that is, a spot experiencing high temperatures.

One property of Kawasaki’s absorbent is that it releases CO2 when exposed to temperatures above 60°C, which means that heat from the engine oil causes the CO2 to separate.

The CO2 thus released is passed through the recovery fluid, bubbling away as it dissolves.

GR Vehicle Development Division Project General Manager Naoaki Ito, who oversees the hydrogen engine project, explains the significance of tackling this technology.

“Typically, facilities for capturing CO2 from the atmosphere use fans to suck in air and heat to detach the CO2, all of which requires energy. The key point about the H2 Corolla’s system is that it uses the existing air intake and heat within the engine.”

That is what makes this technology revolutionary—the fact that it requires no new energy to capture CO2 and can be incorporated into any vehicle with an engine.

Of course, there is still plenty of room for improvement. The amount of CO2 captured remains limited, totaling just 20 grams over 20 laps of Fuji Speedway (4.563 km per lap). And the filters must be replaced by hand at every pitstop.

Moving forward, the team will seek to increase capture volumes and automate filter replacement, working toward a more effective system that requires less human intervention.