Hydrogen engines are two-thirds of the way to production, continuing to evolve through both racing and public road trials.

Hydrogen-powered HiAce trials

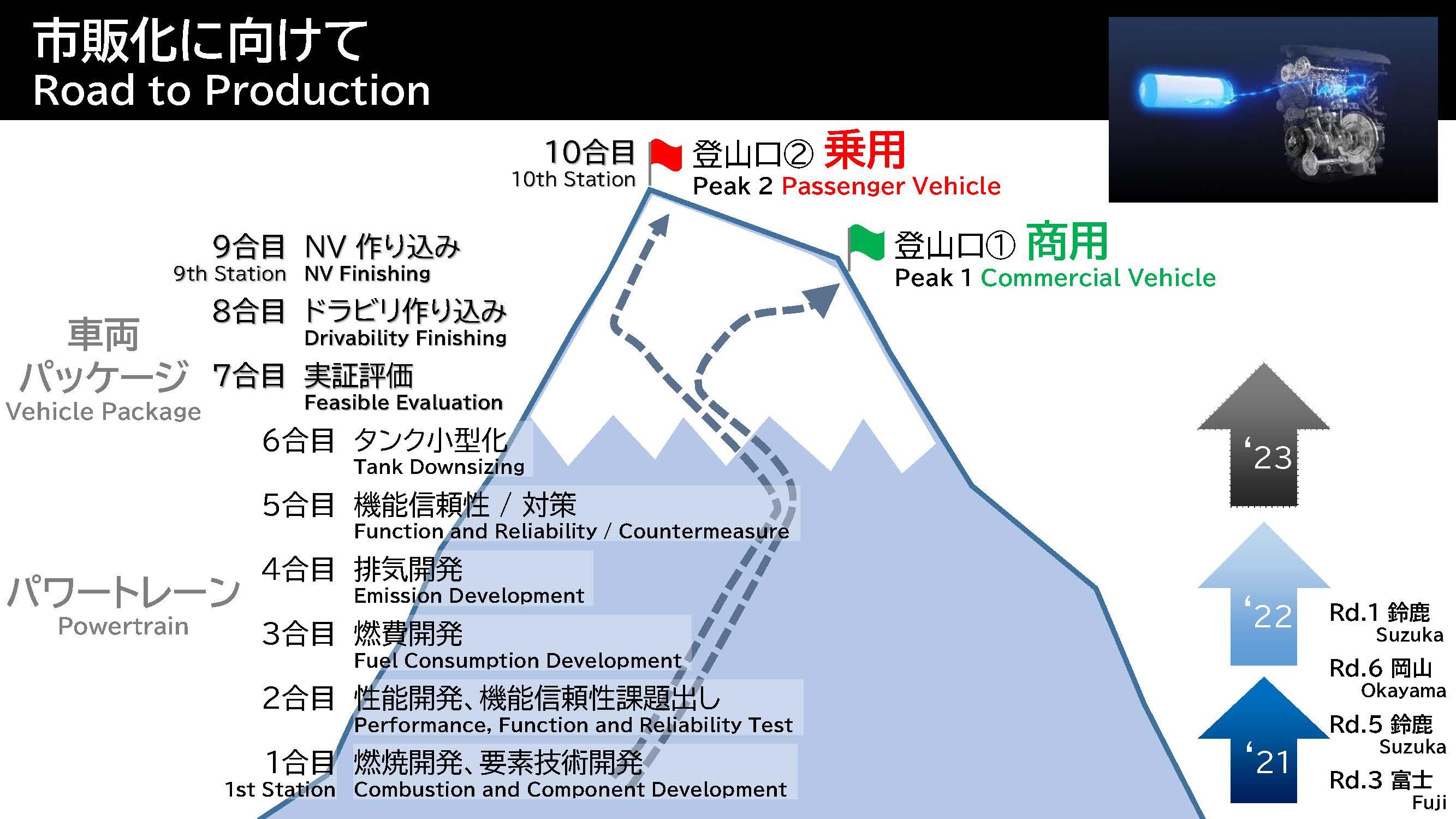

At the Fuji 24-hour race in June 2022, Toyota likened the commercialization of hydrogen engines to climbing Mt. Fuji, placing progress at the fourth station.

In the diagram used on that occasion, the seventh station reads “Feasible Evaluation.”

Ahead of this season’s final round, on November 10, Toyota announced that it had begun such an evaluation with public road trials of a hydrogen-powered HiAce in Australia.

This is a sign that the hydrogen engines Toyota has honed through motorsport are starting to make a mark in everyday life and business situations beyond the racetrack.

For this HiAce, the challenge was to achieve the same packaging as the conventional engine version, retaining the cargo area size and passenger capacity while offering a cruising range of around 200 km.

Racing is a very demanding environment that relies heavily on an engine’s high output and high RPM range. For use in commercial vehicles, however, a different kind of performance is required.

In addition to frequent stopping and starting, the vehicle’s weight can change dramatically when an empty rear space is loaded with heavy cargo.

These aspects will be tested in Australia, which is said to span 80% of the world’s diverse road conditions, with data being collected to refine the technology further.

For more on the trials in Australia, make sure to watch our report on Toyota Times News.

One requirement for driving on public roads is compliance with exhaust emission regulations. Although burning hydrogen gives off no CO2, it does emit nitrogen oxides (NOx).

To curb these emissions, trial vehicles are fitted with the same urea solution aftertreatment systems used in diesel engines.

The result complies with the EU’s Euro 6 automobile exhaust emission standards.

Having achieved the same user-friendliness as conventional engine vehicles, the hydrogen HiAce must now meet expectations for a longer cruising range.

Responding to questions from the press during an interview, Executive Vice President Hiroki Nakajima noted the potential of novel tank shapes—replacing the current cylinders—and hybridization as technical solutions for increasing range.

He also emphasized that “volume is key” in lowering the cost of hydrogen-engine vehicles and expressed his ambition: “Starting with commercial vehicles, we want to establish an infrastructure that can be effectively used for passenger cars to drive steady expansion.”

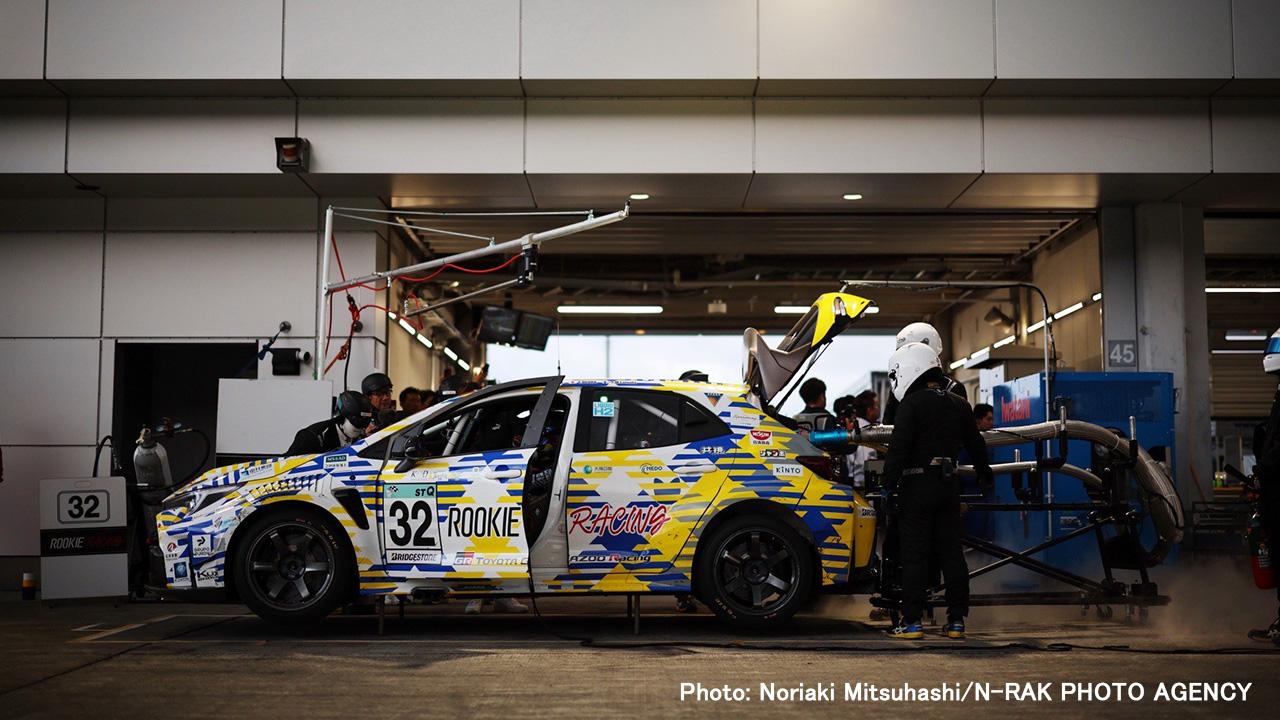

Agile development speeds up again

The 2023 Super Taikyu season brought major milestones for hydrogen engines, from the use of liquid hydrogen fuel to the start of public road trials.

In terms of race appearances, however, the team fell short of last year’s total.

Running on gaseous hydrogen, last season the car competed in all seven rounds. This year, it managed just three. GR Company President Tomoya Takahashi explained the reasons.

“Up to last year, we worked mainly on tweaking the control systems to boost output. This year, however, we’ve made more and more changes to the hardware while also reducing weight. Monozukuri requires blocks of time to be set aside, which is why we scheduled in these intervals.”

Indeed, the tanks alone tell the story. With gaseous fuel, the team simply borrowed those from the Mirai FCEV, but for liquid hydrogen, most parts had to be designed and manufactured from the ground up.

“During that period, we also took the GR Yaris out for three runs, which will help us to release a better product for the model’s next update. One of the focus areas this year was exploring how best to connect motorsports to our products,” says President Takahashi.

Agile development is about flexibly revising approaches to different tasks and challenges. With multiple new technologies being tested in tandem, Toyota’s Super Taikyu endeavor continues to expand. The motorsport-driven development of ever-better cars shows no signs of slowing down.