Subaru, Mazda, and Toyota's technology chiefs provided updates on their next-generation engine development. We take an in-depth look at these new technologies, which build on each company's unique offerings.

On May 28, Subaru, Mazda, and Toyota came together for the Multipathway Workshop, showcasing their commitment to new engine development in the electrification era.

After the three CEOs shared their thoughts on development, the Chief Technology Officers (CTOs) came out to explain their new engines.

With their competitive spirits, the three companies constantly hone their technologies by facing off on the racetrack.

Naturally, that passion also came out when the CTOs presented the engines their engineers are developing with pride.

These efforts are not about extending the life of ICEs but rather a rebirth, creating entirely new engines for the age of decarbonization. We take a detailed look at these new technologies, the culmination of each company’s unique approach.

Note: See the end of this article for a basic explanation of in-line, horizontally-opposed, and rotary engines.

Subaru’s next-generation e-BOXER

“If you were just going for efficiency, horizontally-opposed engines are not necessarily always the best option. But what would Subaru be without them? When you think about it, we are the only mass-market brand making horizontally-opposed engines today.”

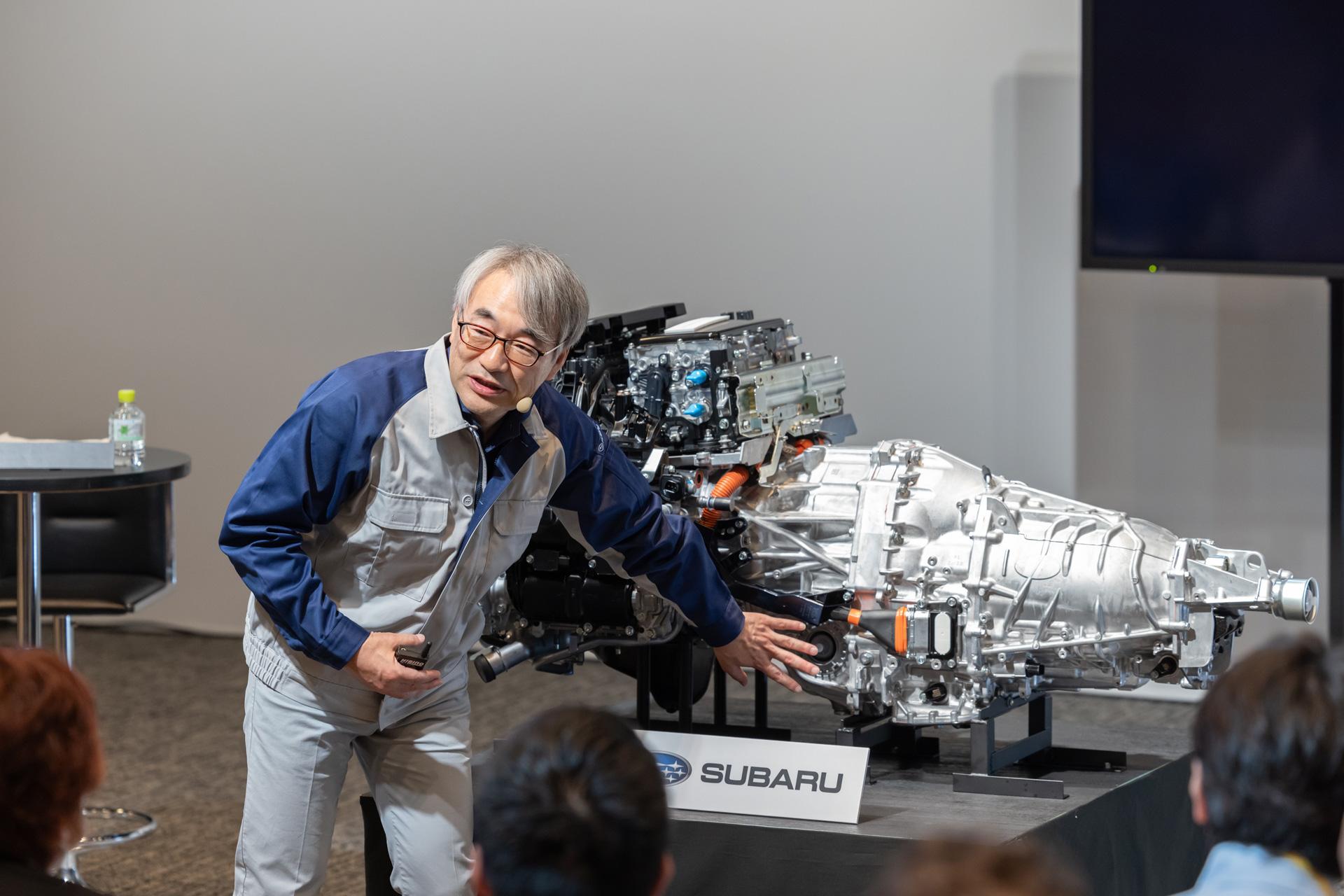

Presenting at Subaru’s booth, CTO Tetsuo Fujinuki spoke about how the company needs to emphasize its identity further to make the brand stand out.

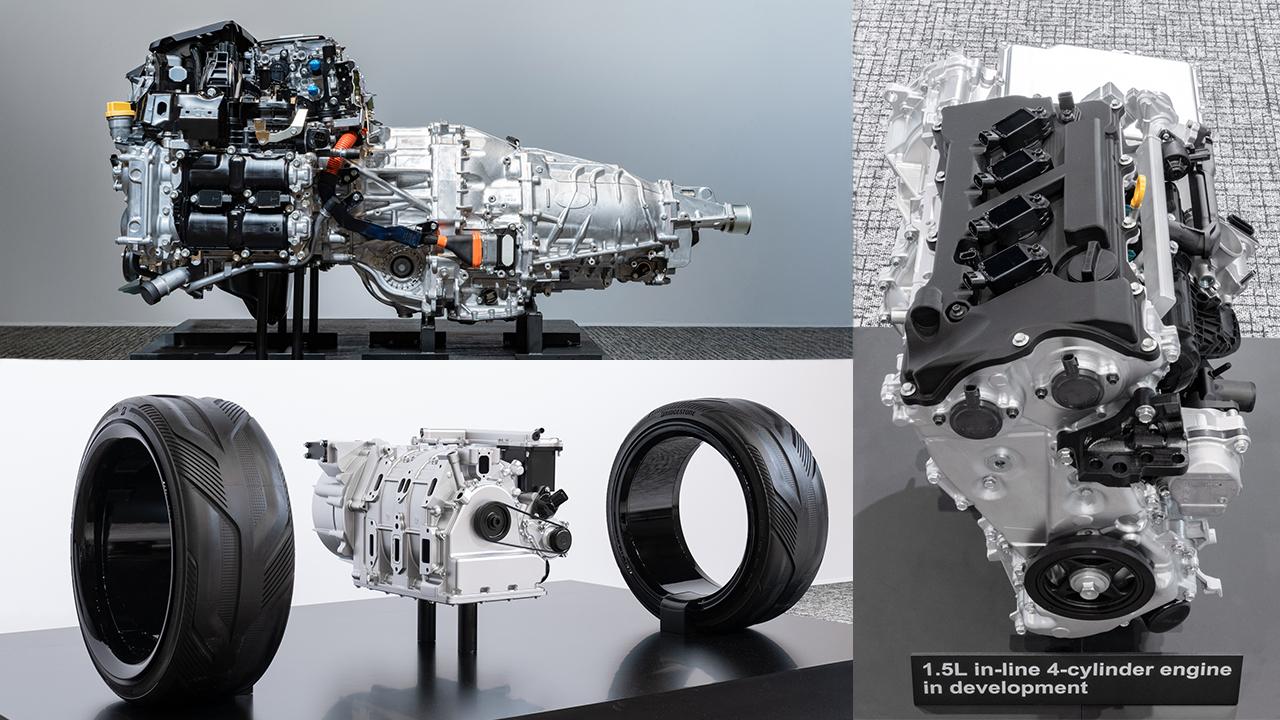

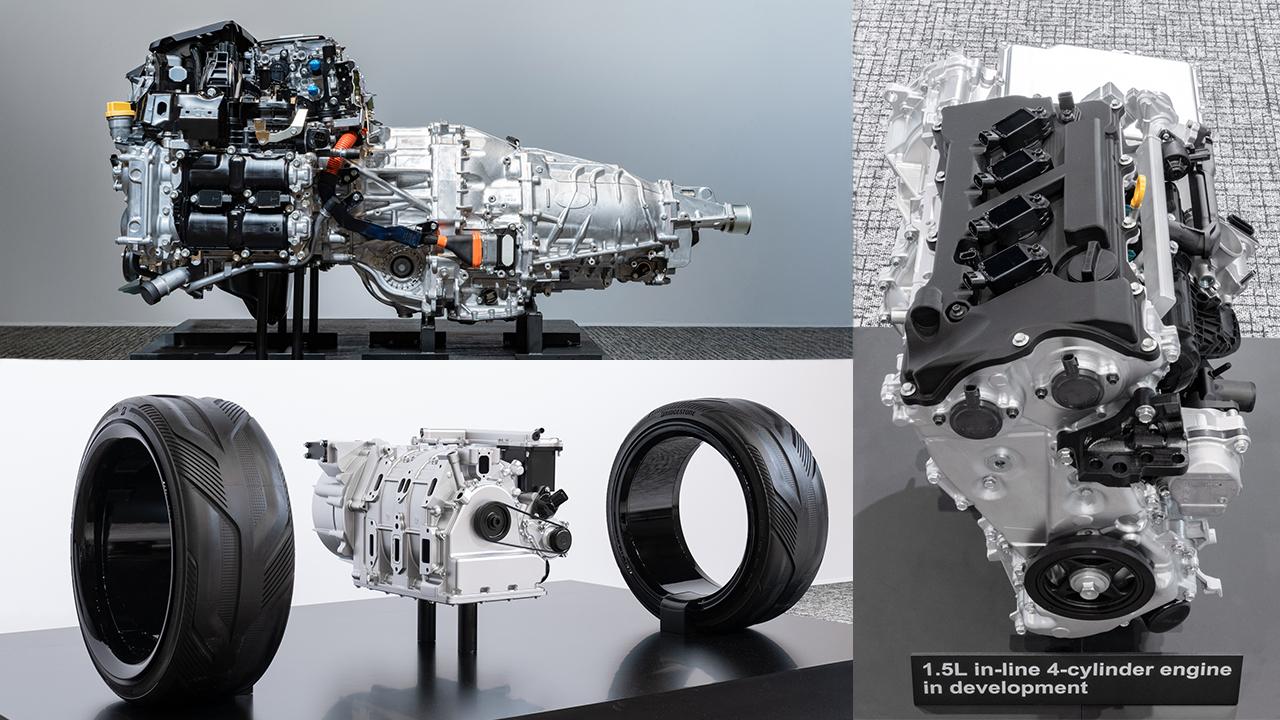

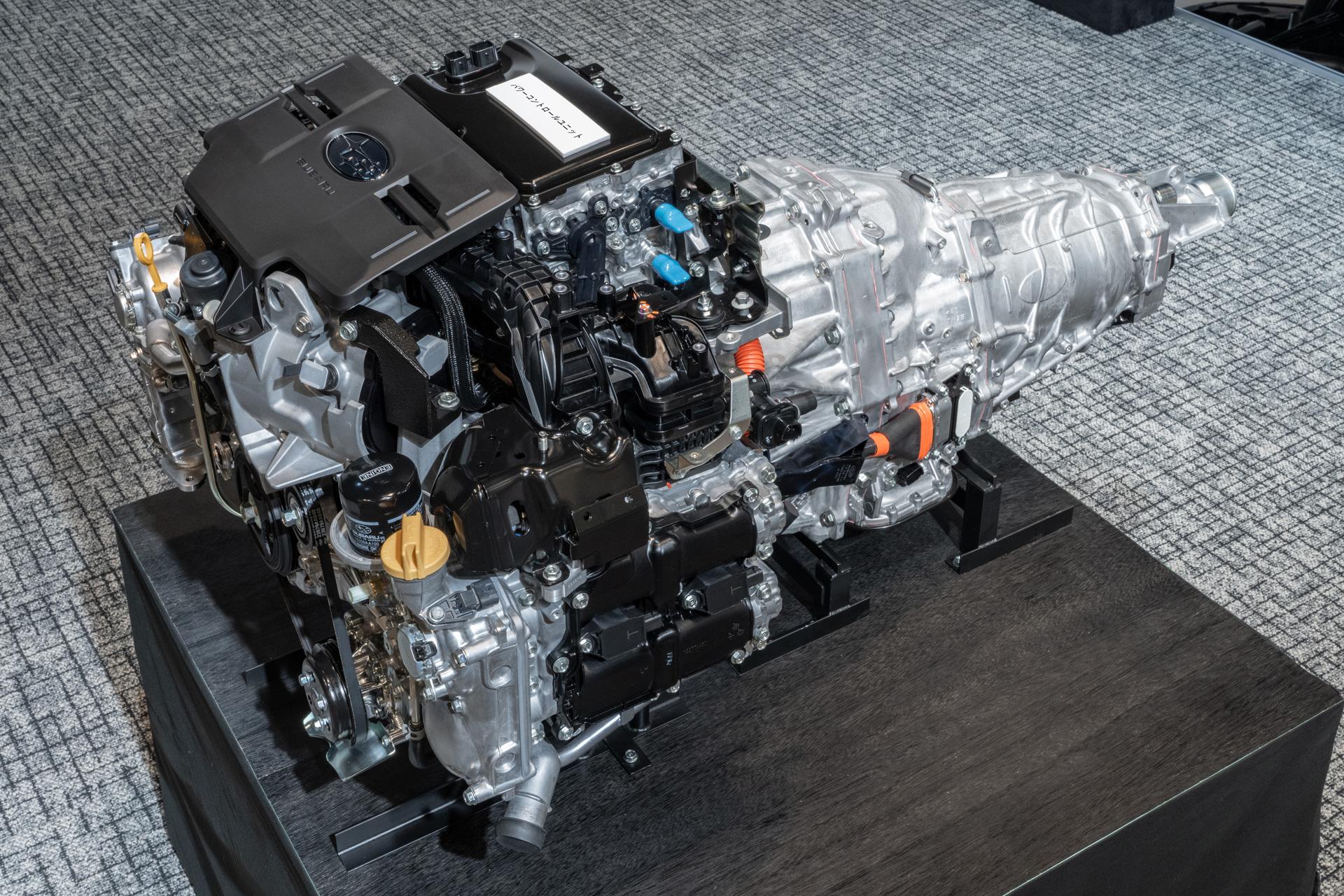

At the workshop, Subaru unveiled a horizontally-opposed engine hybrid system known as the next-generation e-BOXER.

CTO Fujinuki explained the development goal: “To resonate strongly with those who back Subaru, and to improve our current weakness in fuel efficiency.”

In the current e-Boxer, a parallel hybrid configuration uses both the engine and motor to power the vehicle. The new system, however, employs a series-parallel hybrid arrangement, in which the engine directly provides driving force while promising better fuel economy.

The key aspect is the system’s compact size. Behind the slim horizontally-opposed engine sit the differential that drives the front wheels, the hybrid unit’s twin motors and transmission, and the transfer that sends torque to the rear wheels, all housed together.

What’s more, Subaru’s engineers were able to mount the power control unit, which typically takes up some of the fuel tank’s space, in the engine bay. This allows for larger tanks, ensuring the system can also compete well when it comes to cruising range.

To manufacture this hybrid drive unit, Subaru is building a plant in Kitamoto, Saitama, with production scheduled to start this fall.

CTO Fujinuki also mentioned efforts to develop carbon-neutral fuels with Mazda and Toyota and plans to introduce a new vehicle in Super Taikyu—the High Performance X Future Concept—revealing even greater ambitions for co-creation and competition between the three companies.