"Peace of mind" is key to Toyota's battery development concept. What strengths has Toyota cultivated to achieve the aim of this concept? Chief officers leading the effort explain the key points.

Halving battery costs through integrated development of vehicles and batteries

From now, I would like to explain about the batteries of the future.

To popularize BEVs, we would like to reduce costs and provide BEVs at a reasonable price. To start with, we aim to reduce the costs of batteries themselves by 30 percent or more by developing materials and structures.

Then, for the vehicle, we aim to improve power consumption, which is an indicator of the amount of electricity used per kilometer, by 30 percent, starting with the Toyota bZ4X. Improved power efficiency leads to reduced battery capacity, which will result in a cost reduction of 30 percent.

Through this integrated development of vehicles and batteries, we aim to reduce the battery cost per vehicle by 50 percent compared to the Toyota bZ4X in the second half of the 2020s.

Using solid-state batteries starting with HEVs

Please allow me to explain the coming next-generation batteries.

For liquid batteries, we will take on the challenge of material evolution and structural innovation. We will also aim to commercialize solid-state batteries.

As stated, we will develop three types of batteries, and by the second half of the 2020s, we hope to improve the characteristics of each type so that we can provide batteries that can be used with peace of mind.

Next, I would like to explain our initiatives related to solid-state batteries.

We are developing solid-state batteries to see if they can provide the benefits of higher output, longer cruising range, and shorter charging times.

In June last year, we built a vehicle equipped with solid-state batteries, conducted test runs on a test course, and obtained driving data.

Based on that data, we continued to make improvements, and in August last year, we obtained license plate registration for vehicles equipped with solid-state batteries and conducted test drives.

There are some things that we have learned during the development process. Solid-state batteries are expected to have higher output because of the fast movement of ions within them. Therefore, we would like to take advantage of the favorable properties of solid-state batteries by also using them in HEVs.

On the other hand, we found that short service life was an issue. To solve this and other issues, we need to continue development, mainly of solid electrolyte materials.

We feel that having identified an issue has brought us one step closer to commercialization.

One of the reasons that Toyota is starting with HEVs is because it wants to introduce solid-state batteries to the market as soon as possible, gain customer feedback, and continue to evolve them.

Rather than building a large-scale production line for BEVs, which require a large number of batteries, it is better to start with HEVs, which have smaller batteries and a development process with which Toyota is familiar. This would allow solid-state batteries to be introduced to the market faster, as well as enable improvement of the manufacturing technology for them. This could be said to be Toyota’s unique approach for dissemination.

Flexible battery supply

The establishment of a battery supply system is also important for the dissemination of BEVs.

With the rapid expansion of electrified vehicles, we are working to build a flexible system that can stably supply the required volume of batteries at the required timing while meeting the needs of various customers in each region around the world.

In pursuit of our battery development concept of achieving batteries that can be used with peace of mind, we will establish the needed technologies by conducting a certain amount of in-house production, and we will cooperate and collaborate with partners who understand and will put into practice our concept. We will also proceed with discussions with new partners in some regions.

We are building a system with our partners that will allow us to incorporate into discussed plans the volume of batteries that we will need in about three years.

Within the Toyota Group, we are also working to shorten the lead time for the start-up of production and to establish a system that is adaptable to change.

The approach to production within the Toyota Group can be described as “starting up using small basic units”. According to CPO Okada, the lessons learned from the global financial crisis have not been forgotten.

“Going big (with production lines) during (production volume) growth made clear to us our weakness in dealing with change. Because it’s difficult to notice latent risks when production is growing, we have to take a risk-controlled approach to growth based on Toyota's philosophy of ‘making only what is needed, when it is needed, and only in the amount needed’.”

One issue is that the basic structure is not permanent—a new technology becomes available when the manufacturing costs of the previous ones finally come down and the situation gets stable.

Toyota’s strategy of “starting up using small basic units” is meant to enable the company to respond to such changes.

Investment of 1.5 trillion yen by 2030

This summarizes our development and supply of batteries by 2030.

In development, we will aim to achieve a per-vehicle cost of 50 percent or less compared to now through the integrated development of vehicles and batteries.

In terms of supply, we will respond flexibly to the changing needs of our customers. For example, we are assuming that we will go beyond the 180 GWh worth of batteries that we are currently considering and will ready 200 GWh worth of batteries or more if the dissemination of BEVs is faster than expected.

The amount of investment in the development of a battery supply system and research and development, as I have just explained, is expected to be approximately 1.5 trillion yen by 2030.

By establishing a system for both development and supply, we will promote the dissemination of electrified vehicles, including BEVs.

On the way to our goal of achieving carbon neutrality in 2050, the energy situation and infrastructure of each region, as well as the sensibilities and convenience requirements of customers, will continue to change.

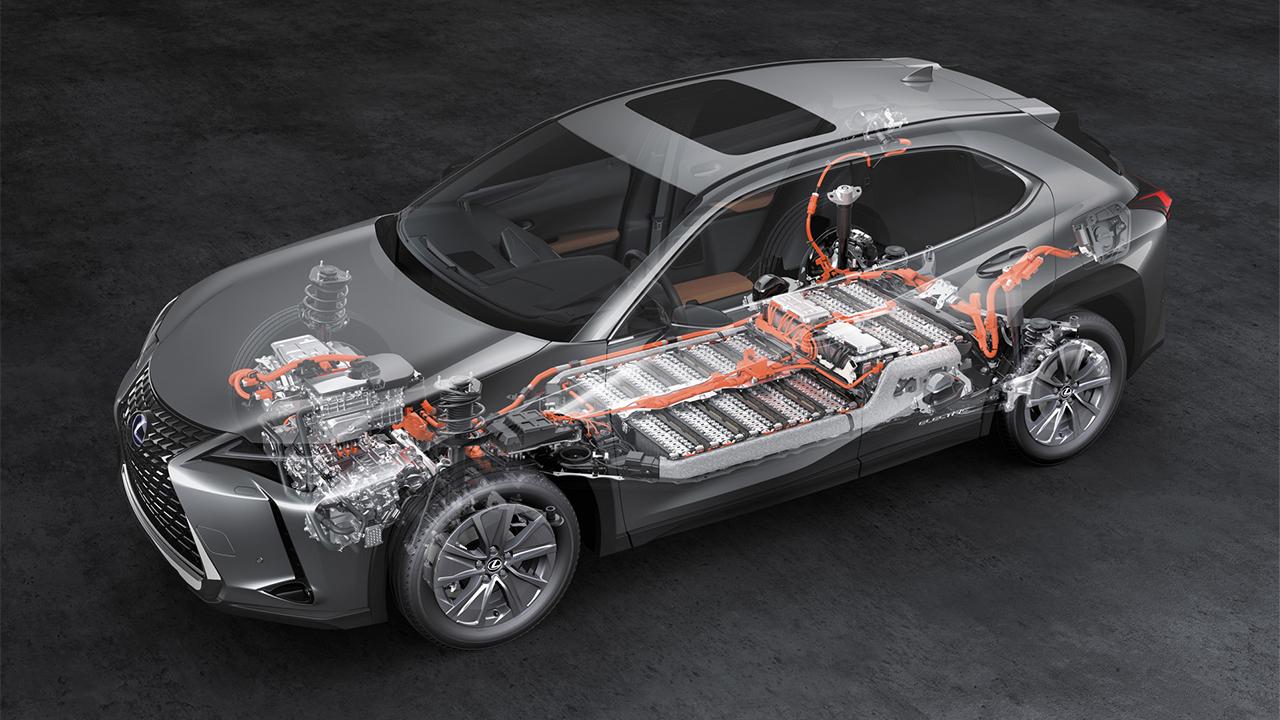

When it comes to electrified vehicles, cars and batteries should be regarded as one set of products. Toyota, which has been committed to producing batteries within the Toyota Group since 1997 and whose market-introduced HEVs, alone, number 18.1 million units, is an automaker that has been working on battery development as a corporate group, and, into the uncertain future of electrified vehicles as well, it intends to move forward in sure-footed steps.

To adapt to the future sustainably and practically, Toyota would like to contribute to the achievement of carbon neutrality by improving its adaptability to change and its competitiveness, as well as by aiming for the fundamental widespread acceptance of ever-better electrified vehicles.

The investment amount of 1.5 trillion yen includes development and supply, including batteries for HEVs, with the investment in new battery production lines accounting for about 1 trillion yen of that.

10 production lines will be opened by 2025, and from 2026 to 2030, a total of as many as 70 production lines for BEV batteries will be introduced at a pace of 10 lines per year.

Okada said: “We will limit the production volume and the number of team members per line, shorten the lead time for line introduction, and make it easier to nimbly respond to needs. When it comes to investment in production lines, as well, we will use our expertise in HEV battery production lines to reduce costs.”

Toyota’s strengths

Investment of 1.5 trillion yen by 2030, increasing production capacity to more than 200 GWh per year, and increasing the number of production lines to 70—all of the figures announced at the press conference were large in scale.

Also, the company’s strengths for making the most of this investment are found in its knowledge of battery development, which has been steadily and earnestly accumulated since the development of the first-generation Prius, and in its planned integrated development of vehicles and batteries.

To provide peace of mind to customers using their vehicles in various ways, Toyota is pursuing the possibilities of all types of batteries, including nickel, lithium, and solid-state batteries. Not only for electrified vehicles but also batteries, Toyota is marching forward with a full lineup strategy.