At the final round of the 2025 Super Taikyu Series, Toyota revealed a year of progress in hydrogen. How much closer has it come to realizing a hydrogen-based society? Here is a snapshot of the progress so far.

On November 16, the final round of the 2025 Super Taikyu Series was held at Fuji Speedway in Oyama, Shizuoka Prefecture. A GR Corolla powered by liquid hydrogen (the liquid hydrogen Corolla) successfully completed the four-hour race, covering 109 laps.

This marked the liquid hydrogen Corolla’s first Super Taikyu appearance in six months, following the Fuji 24 Hours race in May. With the fuel pump’s durability now largely confirmed, the car completed the race at maximum output.

At the same time, hydrogen-related initiatives extend well beyond the racetrack. Significant progress was also made off the circuit. How far did Toyota advance this season toward a hydrogen-based society? This report takes a closer look at those efforts.

Superconducting Technology: All Upside?

Superconducting technology has drawn considerable attention since Toyota unveiled its concept in May 2023.

Superconducting technology reduces electrical resistance to zero in ultra-low-temperature environments, allowing current to flow with no power loss. It is already being applied across a wide range of fields, including transportation, energy, and medicine.

In the liquid hydrogen Corolla, the technology was applied to the motor that drives the fuel pump, making use of the fuel’s temperature of −253°C.

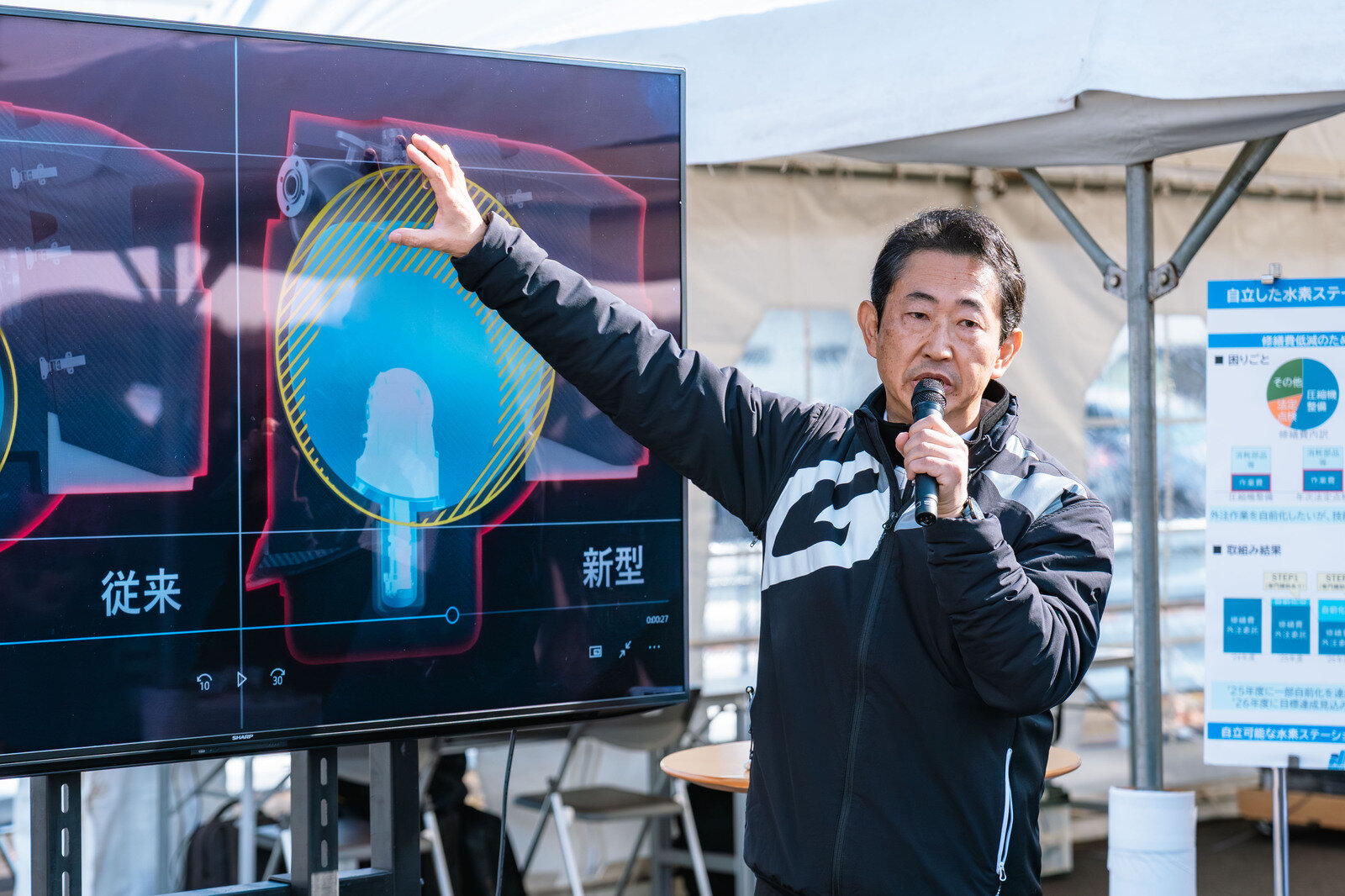

On November 15, during qualifying for the final round of the Super Taikyu Series, the liquid hydrogen Corolla equipped with superconducting technology made its first demonstration run.

Behind the wheel was driver Masahiro Sasaki of TOYOTA GAZOO ROOKIE Racing.

Delivering a light and responsive drive, Sasaki commented on the car’s refinement, saying, “The positioning of the center of gravity has improved significantly. It is lower, and my impression is that body roll has been reduced to almost nothing.”

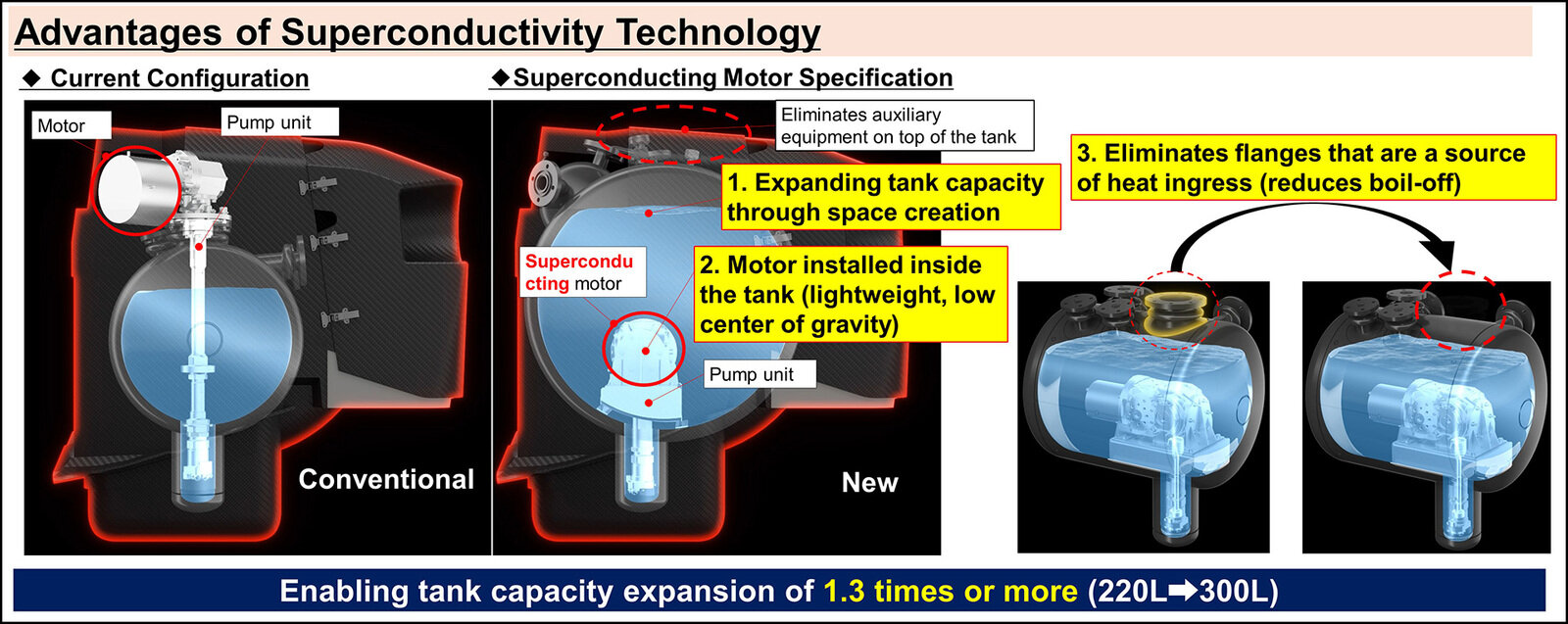

Naoaki Ito, Project General Manager of the GR Vehicle Development Div. overseeing the hydrogen engine project, said, “There is strong compatibility between liquid hydrogen-powered vehicles and superconducting technology. It’s a key technology for the future.” He then outlined three key points.

- Eliminating auxiliary equipment around the pump previously located above the tank allows for increased tank capacity.

- Housing the motor inside the tank enables a more compact design due to reduced electrical resistance, contributing to weight reduction and a lower center of gravity.

- Removing flanges that act as sources of heat ingress helps reduce hydrogen loss that previously occurred through boil-off.

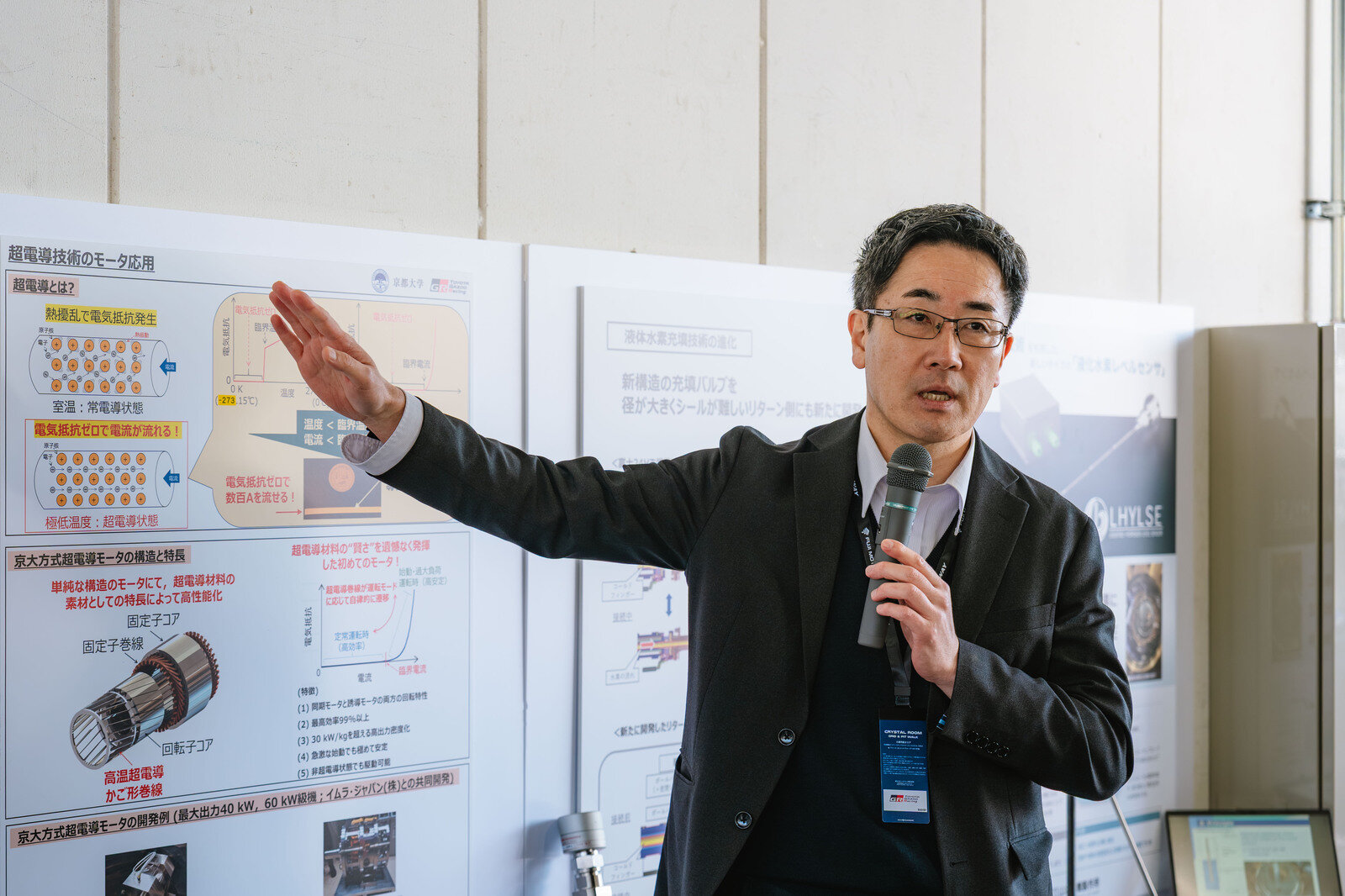

Taketsune Nakamura, Program-Specific Professor at Kyoto University, collaborated on the development. “The superconducting motor is made using commercially available superconducting wire. Simply put, you just wind it into coils. There is basically nothing else special required. And yet, performance improves dramatically,” he said.

In addition, the system can adjust resistance automatically in response to the motor’s operating mode. A fail-safe function activates if the temperature inside the tank were ever to rise to near room temperature.

At first glance, superconducting technology may seem to offer nothing but advantages. However, there are still challenges to overcome.

When the amount of the liquid hydrogen fuel is low, the superconducting motor can become exposed above the liquid level, causing its temperature to rise and reducing superconducting performance.

Another challenge lies in the durability of metal components. In the ultra-low-temperature environment of liquid hydrogen, metals undergo thermal contraction, and lubricants such as oils cannot be used.

Ito expressed his determination to address these issues, saying, “We want to work closely with Japanese companies that possess cutting-edge technologies to steadily advance technical improvements. We also hope to build a broader network of partners.”

Hydrogen Engine HEV HiAce

The next cutting-edge technology is the hydrogen engine hybrid electric vehicle (HEV). In November 2024, Toyota unveiled a HiAce equipped with this system for the first time at the final round of the 2024 Super Taikyu.

At the time, the vehicle was configured as an 11-passenger model, with the front passenger seat space repurposed to accommodate the system. This time, it has been upgraded to a 12-passenger configuration, restoring the usability expected of a “standard HiAce.”

Hirofumi Ota, CV Company Chief Engineer, described its significance as follows.

“Last year, we brought the vehicle just one week after combining a hydrogen engine with an HEV system for the first time. It was essentially a development vehicle, with electric components and measurement equipment occupying the front passenger seat,” he said. “This time, it is a normal vehicle. For a commercial vehicle, being a ‘normal car’ that can handle everyday work is what matters most. If you ask what has evolved, it is the return of the front passenger seat. But to make that possible, we thoroughly pursued component downsizing and further developed the performance of the underlying powertrain.”

In 2023, before being converted to an HEV, the hydrogen engine HiAce underwent demonstration testing in Australia, where the vehicle was put through its paces.

At the time, driving range was one of the key challenges, and the hydrogen engine HEV HiAce demonstrated a viable solution. In 2026, it is scheduled to return to Australia for further demonstration testing.