A secret room filled with plastic models and figurines. How does this help Toyota achieve a completely circular resource cycle where nothing is thrown away?

Kokeshi dolls, dinosaurs, primitive-looking clay figures, and even anime figurines and manga.

All this and more can be found in a secret room at Toyota, where items that have nothing to do with cars have been gathered for a special purpose.

They were collected to analyze the structures of different objects, in the hope of finding clues that could open up new directions in vehicle design. Among the collection is a stuffed okapi toy.

Considered one of the world’s rarest animals, the okapi is a mammal belonging to the giraffidae family, which it shares with only one other species: giraffes.

Surely it couldn’t have anything to do with carmaking… so you might think but read on to find out.

An unusual job title

This initiative is led by Koichi Daigaku of Toyota Structure Design Studio.

His position is Theme Producer. Of Toyota’s roughly 380,000 global employees, only two or three have this job title.

Koichi Daigaku, Theme Producer

Although the Structure Design Studio counts as one of the company’s departments, instead of having a “general manager,” we use titles that make it easier for others to understand what we do.

Our chief task is to come up with vehicle structures that are lightweight and highly rigid, while using fewer parts and remaining inexpensive.

We search for new ways of making cars by exploring how changes to parts or assembly methods affect performance. That is why we emphasize free thinking.

Valuing roles over job titles, Daigaku launched the Structure Design Studio in 2021, pursuing what he calls Geological Design.

This approach seeks to make cars and give objects new life such that nothing is thrown away, creating a completely circular resource cycle.

With a single car consisting of some 30,000 parts, is complete recycling of resources even possible? Despite the extremely high level of difficulty, Daigaku says, “We have no choice.”

Theme Producer Daigaku

The catalyst was seeing a car scrapping facility.

I was shocked by how much is thrown away. Of course, some of the scrap is used in construction or to pave roads, but ultimately, new cars are mostly made up of fresh materials. I realized that the process wasn’t truly circular.

Take glass, for example. To protect users, automotive glass is made very strong and hard. Consequently, it melts at higher temperatures, which means that recycling requires a lot of energy.

Generally, using new glass is less expensive than thinking about reuse. That makes it better for customers as well. But then, the amount of waste just continues to grow.

How do you resolve the issues of both cost and resource recycling? While pondering this question, one day, Daigaku made an important decision.

Theme Producer Daigaku

Toyota makes up to 10 million vehicles a year, which means that we also produce a lot of waste. As the engineering departments that create products, we have to confront this reality.

Ideally speaking, the best solution might be to stop making things altogether, but we cannot deny our customers the joy of mobility.

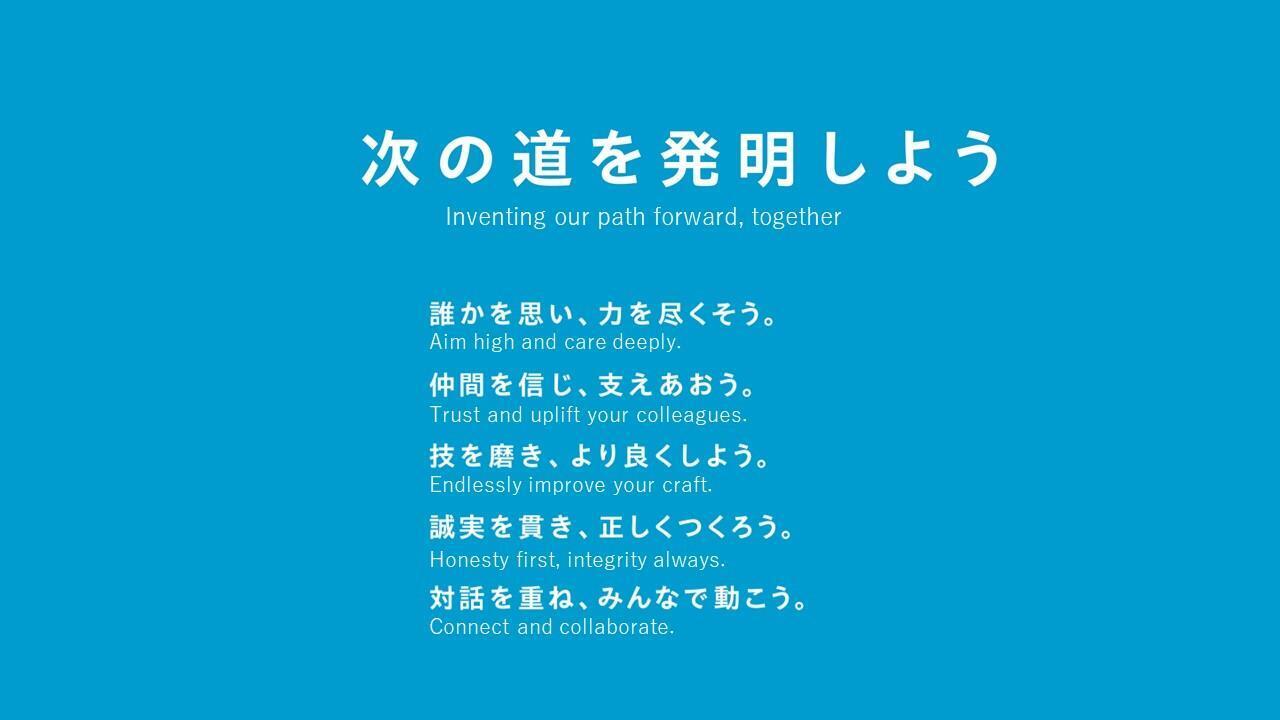

As we were grappling with this problem, Chairman Akio Toyoda unveiled Toyota’s Group Vision, “Inventing our path forward, together.” Within our team, we set out to redefine what it means to create a good car.

In addition to conventional carmaking, we aimed for a new approach in which nothing was thrown away, while also attaching value and giving new life to unavoidable waste and establishing the necessary partnerships. In this way, Geological Design became our goal.

Geological Design approaches the resource problem from two angles: end of life and start of life.

First, on the “end of life” side where waste cannot be avoided, the materials are upcycled into art pieces or craft products, turning trash into something of value.

“Start of life” efforts involve reducing the number of parts or changing the types of materials used in cars. To achieve this, Daigaku’s team also aims to reduce the weight of the cars themselves.

For example, what happens if you make a car 100 kg lighter while also boosting body rigidity? Visiting the Structure Design Studio offices, we found a driving simulator hooked up to a gaming console. What was all this about?