A group of Toyota engineers and technicians volunteered to develop a prosthetic blade for Keita Sato, a para-athlete and colleague. Behind the challenge, there was a story of countless failures and kaizen in pursuing a better prosthetic blade.

Athletes stand on the podium with the crowd cheering and cameras flashing. But they don’t make that happen just by themselves. Various people, from coaches, friends, colleagues, rivals, to families provide them with support, and behind a success or struggle, there are many different stories for each athlete. This athlete series highlights what enables athletes to take on challenges.

Customized prosthetic blades for competitive sports

Attention has been focusing on prosthetic blades for competitive sports over the last few years. The German gold medalist in the long jump (T44) with a prosthetic blade at the Rio 2016 Paralympic Games set a personal record of 8.48m in 2018. This jump would have won him the gold medal in the long jump at the Olympic Games Rio 2016. Prosthetic blades for competitive sports have the potential to even break the records of athletes with no physical disabilities.

However, the development of prosthetic blades is not a simple process. The body build and condition of the legs differ from person to person. There are also athletes who use both legs equally when they run, while others may rely more on the use of their prosthetic blade.

In other words, prosthetic blades for competitive sports must be customized to fit each individual athlete.

For Keita, who only owned one prosthetic blade!

Keita Sato, who won the bronze medal in the 4x100m relay (T42-47) at the Rio 2016 Paralympic Games, and joined Toyota Motor Corporation that year, only owned one prosthetic blade at the time. The fact that even a top-class athlete can only own one prosthetic blade testifies to the difficulty of making them, including their cost.

Only having one prosthetic blade is dismal, and if something happens to it, you can’t practice anymore. We wanted to make Keita a new prosthetic blade to compete with.

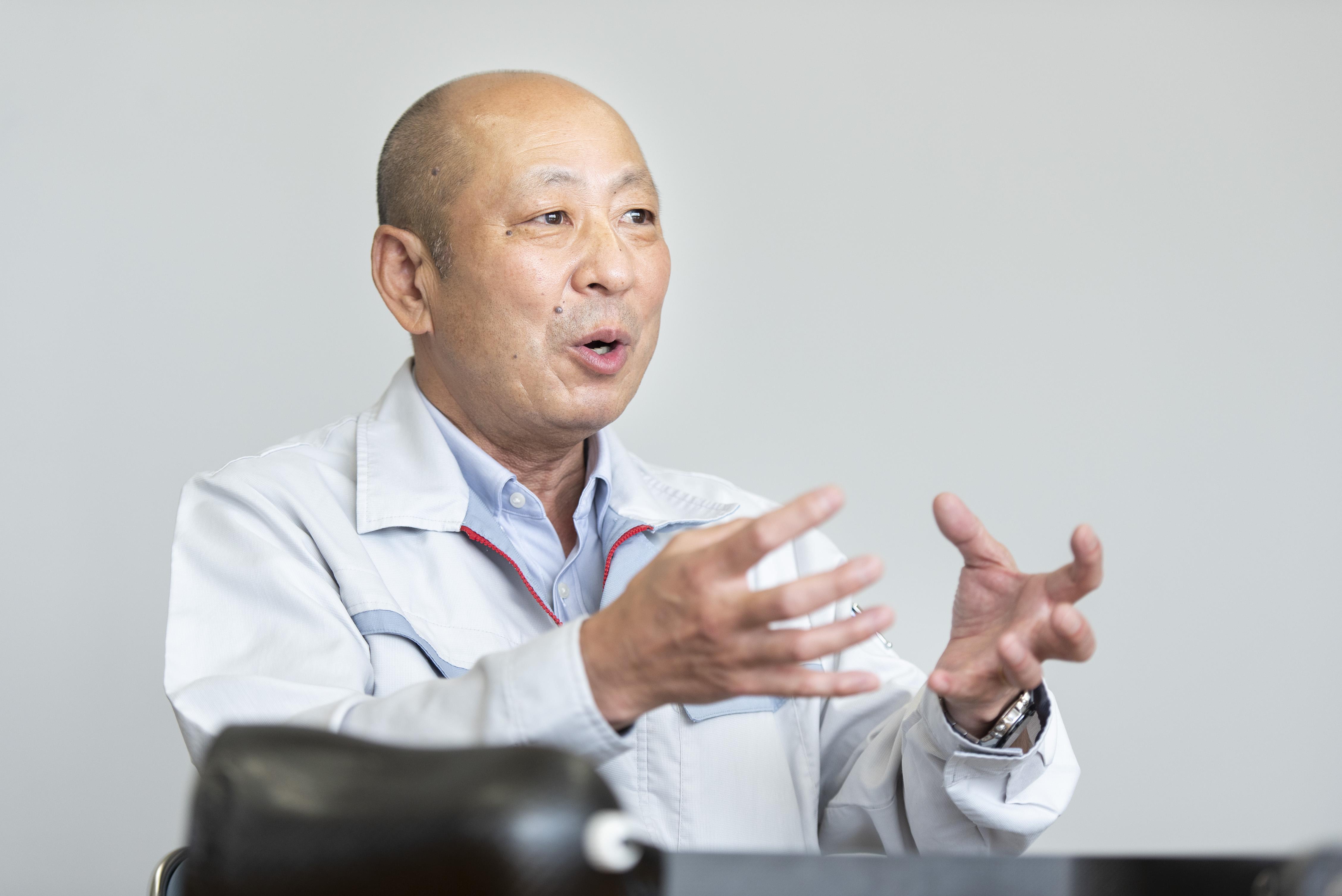

Keita was assigned to the Production Engineering Planning Division after joining Toyota, and it was in 2017 that his supervisor announced this at a meeting for management members at Toyota Motor Corporation.

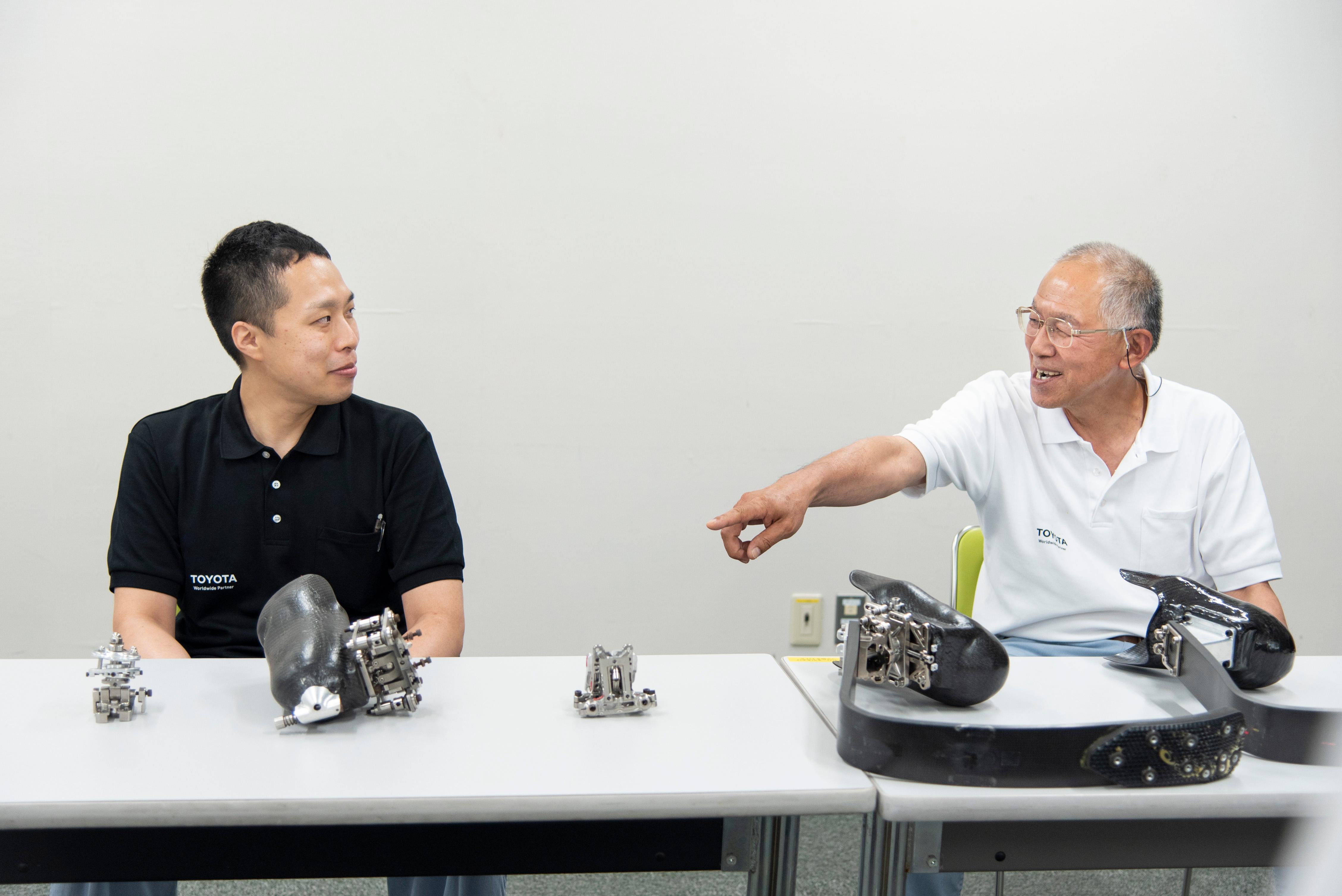

This was the start of the Prosthetic Blade Development Support Project. The mentor-pupil duo of Kenji Ueda of the Production Engineering Division, and Yuya Kaburagi, who calls Ueda his “master,” were placed in charge of designing the alignment parts, including the abutment and plug connector, which are particularly difficult to develop. Incidentally, Kaburagi is the same age as Ueda’s youngest daughter.

Starting through trial and error, but immediately hitting a brick wall

In May 2017, Ueda was placed in charge of developing the alignment parts for the prosthetic blade for competitive sports, and he thought to himself, “This is going to be a huge challenge.” The alignment parts connect the socket which the amputated leg is inserted into, to the blade (a plate spring), which comes into contact with the ground, and they must be light and durable. Ueda reflects on what was so challenging about developing these parts.

Of course, I’d never made alignment parts before. I didn’t have blueprints or anything, and had to begin through trial and error. I consulted a junior colleague who uses a prosthesis, but was told that those used in everyday life and for sports were different. So, I was at a complete loss as to what I could do.

Incidentally, the socket into which the amputated leg is inserted was also made through the Prosthetic Blade Development Support Project run by volunteers from Toyota Motor Corporation based on advice from a prosthetist (a specialist in developing and fitting prostheses). They made use of the advanced technologies and skills of the Raw Material Development Division and Motomachi Plant Body Manufacturing Division, which in itself is another story that needs to be told.

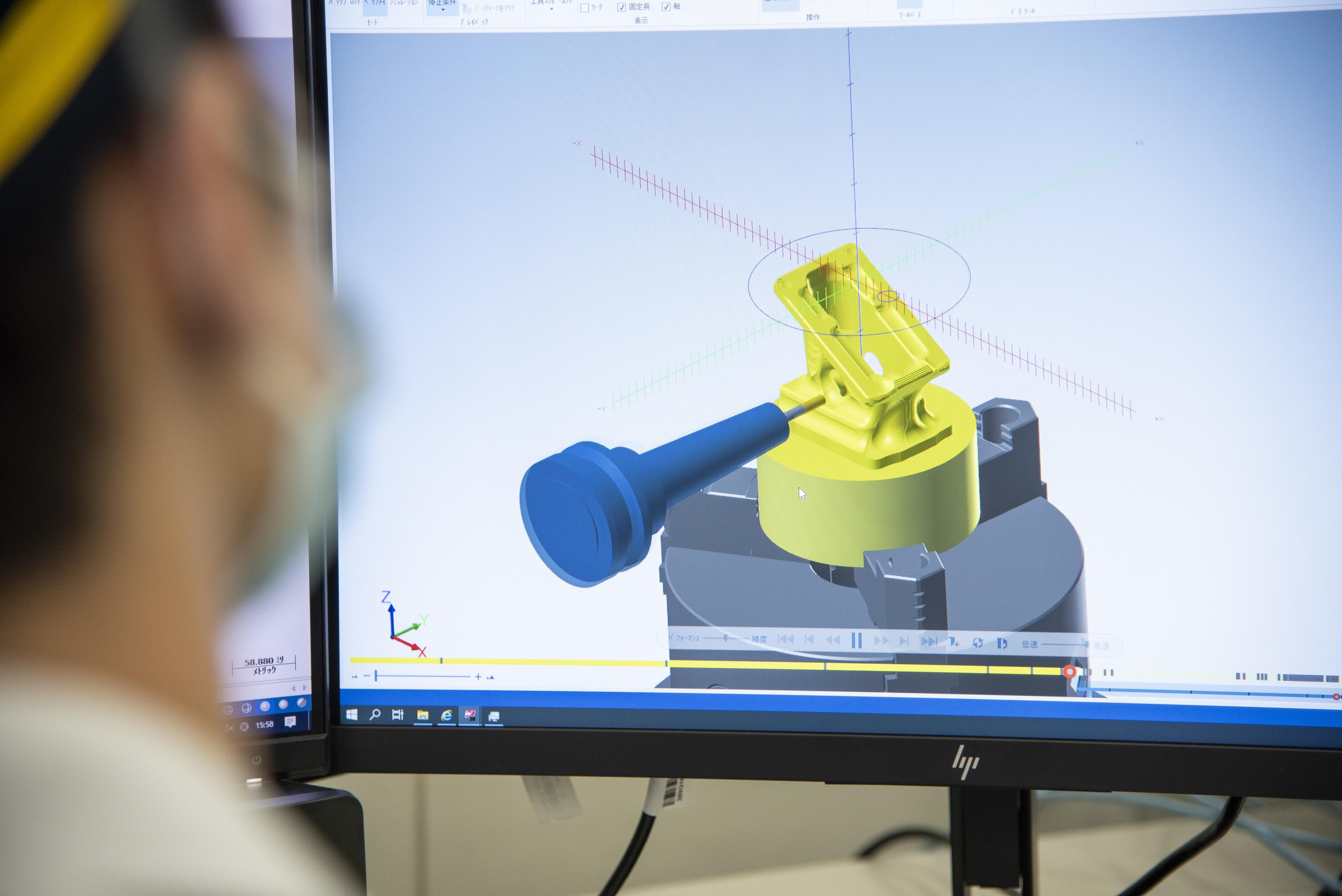

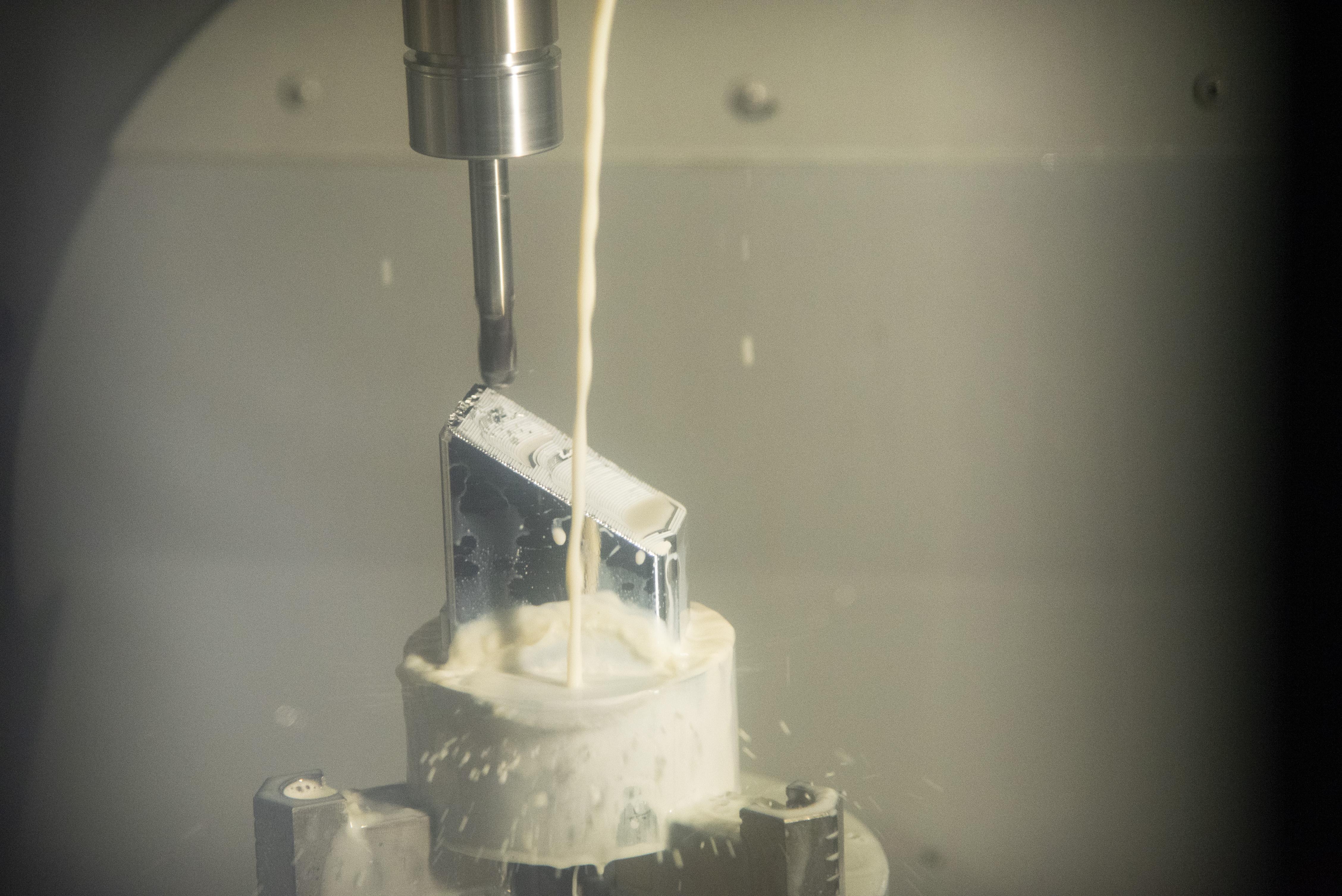

At the time, there was no such thing as a prosthetic blade made specifically for Paralympians. It was usual to use a mass-produced prosthesis for everyday use for sports as well. Ueda and Kaburagi bought a mass-produced prosthesis and analyzed it thoroughly before making a prototype. The two men were initially at a complete loss, but they began developing alignment parts based on their experience in making prototypes of complicated parts for engines and transmissions placed under great stress.

The completion of a prototype and a shocking test run

In December, around six months after development began, Keita was invited for a test run. But this first test run resulted in an accident. Kaburagi stares into the distance as he recalls what happened that day.

I assembled the alignment parts and made adjustments to it before getting Keita to test it. But he’d only jogged about 20m to warm up when it snapped. My head went blank thinking I’d made a terrible mistake. It was the first test run, so, many people had come to watch and there were even plans to make a video to report on the test, but….

Words spoken in the shinkansen on the way home by a senior employee, who had been in charge of machining the alignment parts, were the only consolation.

He gave us encouragement, telling us not to hesitate in asking for anything, because he would make anything for us. The purpose of this project was to cheer for Keita, and there was a sense of solidarity right from the start, breaking down all barriers between divisions.

The reason for the failure was the engineer-centered development

After this shocking incident, the small team of people running this project centered on the mentor-pupil duo of Ueda and Kaburagi was joined in 2018 by Yuji Nishiyama of the Powertrain Management Division. Nishiyama had good knowledge of what skills and human resources could be found in which division, and he gave them advice from an administrative viewpoint, saying things like, “If you’re going to do this experiment, you should discuss it with Mr. X of the Y Division.”

Development would be greatly accelerated with Nishiyama joining the team, or so it seemed… Nishiyama says.

Looking back, I think we were engaging in development for self-satisfaction. We were trying to develop alignment parts that could be adjusted at the time of putting on the prosthesis. But making these adjustments was difficult for Keita, and the prosthesis was also heavy and difficult to use. The extra functions had made it increasingly complicated and heavy.

Doing away with reservation giving birth to “Team Keita”

Development of the prosthesis did not proceed smoothly between 2018 and 2019, and one of the reasons for this was the lack of close communication between the project team and Keita. Ueda says he felt a little annoyed at the time.

Keita wasn’t very forthright in asserting his views. Looking back on it now, I realize that it was probably because he found it hard to criticize something that had been made by a senior employee who was older than his parents. I was expecting him to be frank in telling me how the design was bad, or where it hurt.

Then Keita changed his activity base to Tokyo, which exacerbated the lack of communication. This led to the renting of a restaurant in Toyota City in the fall of 2019 to hold a party. Around 30 people gathered for this party, and Nishiyama explains its objective.

I think Keita had reservations about asserting his views to a much older person, while we too, were in too much awe of the Paralympic medalist. At the time, some of the members still called him Mr. Sato. But there was no room for reservation, and we decided to call him Keita any time. The project team members came together in solidarity to aim for the gold medal, and we decided to call ourselves “Team Keita.”

Harsh words from Keita

The party closed the gap between Keita and Team Keita, and everyone began communicating more frankly. Kaburagi, the person who had been shocked at the first test run, bore the full brunt of Keita’s harsh words.

We visited the place where Keita practiced when we went to the Tokyo Motor Show. There, I was told by Keita’s prosthetist that they didn’t want to use our prosthesis anymore. Keita, too, indirectly criticized our prosthesis, asserting firmly that he wanted a prosthesis like an F1 machine for practical use during races. It was such a huge shock that I can hardly remember what I saw after that at Tokyo Motor Show.

As of the end of 2019, the Tokyo 2020 Paralympic Games were still scheduled to be held in August 2020. It was feared that they would run out of time with only a few months left until the Games.

Gathering an elite team spanning different divisions

Upon entering 2020, test runs were held repeatedly by Team Keita through close cooperation between Keita, his prosthetist, and competitive sports prosthetic R&D company Xiborg. Nishiyama, the leader, gathered information from everywhere within the company whenever a need arose for technologies or human resources. Team Keita won the full support of the entire company, and development of the alignment parts finally began to take off.

Unlike everyday work, all you had to say was, ‘Gather around if anyone’s interested in helping Keita!’ and people from all divisions would just gather naturally. Our first party was attended by about 30 people, but now, I think we’d end up with several times more than that.

A change in the concept leads to unexpected evolution

Keita, too, began telling them that the prosthesis was becoming a lot easier to use, and he began achieving good results. One of the reasons for this was a change in the concept behind the prosthesis. Ueda explains how it changed.

The concept behind our alignment parts was that the angle of the blade could be changed freely according to Keita’s condition. It could be moved 20 mm vertically, 10 mm horizontally, and the angle of the axis could also be changed by 6 degrees in one direction, for a total of 12 degrees. But Keita said the prosthesis was too heavy and difficult to adjust, making it unsuitable for competitive running. This led us to make simple, light and rigid (fixed) alignment parts after ascertaining the optimal settings on the adjustable alignment parts.

The sides of the alignment parts were made with a hollow structure to further reduce their weight. This was well-received and Keita’s running time improved drastically. Keita Sato himself was apparently surprised that a reduction in weight would make such a huge difference. Ueda continues,

We could’ve stopped there, but we thought if weight meant so much, we could make it even lighter. So, we made the sides hollow with triangles forming a truss. Strength is sacrificed in a truss structure, but we designed it to overcome this. A computer analysis (topology optimization) later revealed that I was right in my rationale, and I’m actually quite proud of this (laughs).

Was the project inconsistent to the Toyota Production System!?

Kaburagi who witnessed his mentor striving to further improve the prosthesis, after he thought it had been completed, reflects on this saying, “The effort to continue making further improvements was typical of the Toyota spirit.”

In response to this, Ueda says, “I didn’t think it was at all a typical Toyota project.”

The project was full of muri (overburden) and muda (waste). TPS dictates that we mustn’t do these kinds of things (laughs).

As he says, it may have been a project with a lot of muri and muda. But Kaburagi says they managed to gain a lot through this experience.

We were able to communicate with lots of people spanning different divisions and organizations, and there were insights that we wouldn’t have been able to gain through everyday work.

The alignment parts developed by Team Keita are now sold with the help of Xiborg. Ueda says with passion, “I mentioned a junior colleague of mine uses a prosthetic leg, but while making this prosthesis for Keita, there was a constant thought at the back of my mind that I want to help create a society in which people with leg disabilities can move around freely.”

People at first might have wondered why Toyota was doing this project, but given the company’s mission to create a society in which everyone can enjoy freedom in mobility, this was a project perfectly suited to Toyota.

(Text: Takeshi Sato Photos: Tomoyuki Obokata)