A special project team worked on reviving a Toyopet Racer, Toyota's first racing car from over 70 years ago. In the series' final installment, three young leaders share what they gained through the project.

The Toyopet Racer revival project wrapped up with the finished machine installed as a museum exhibit. Having followed the journey, at last our series also arrives at its final chapter.

In this final part, the three young leaders who spearheaded the project talk about what they took away from this experience. For the final word, we turn to the project’s instigator, Corporate Citizenship Division General Manager Naoaki Nunogaki, who serves as Director of both the Toyota Automobile Museum and the Fuji Motorsports Museum.

Building a car with our own hands

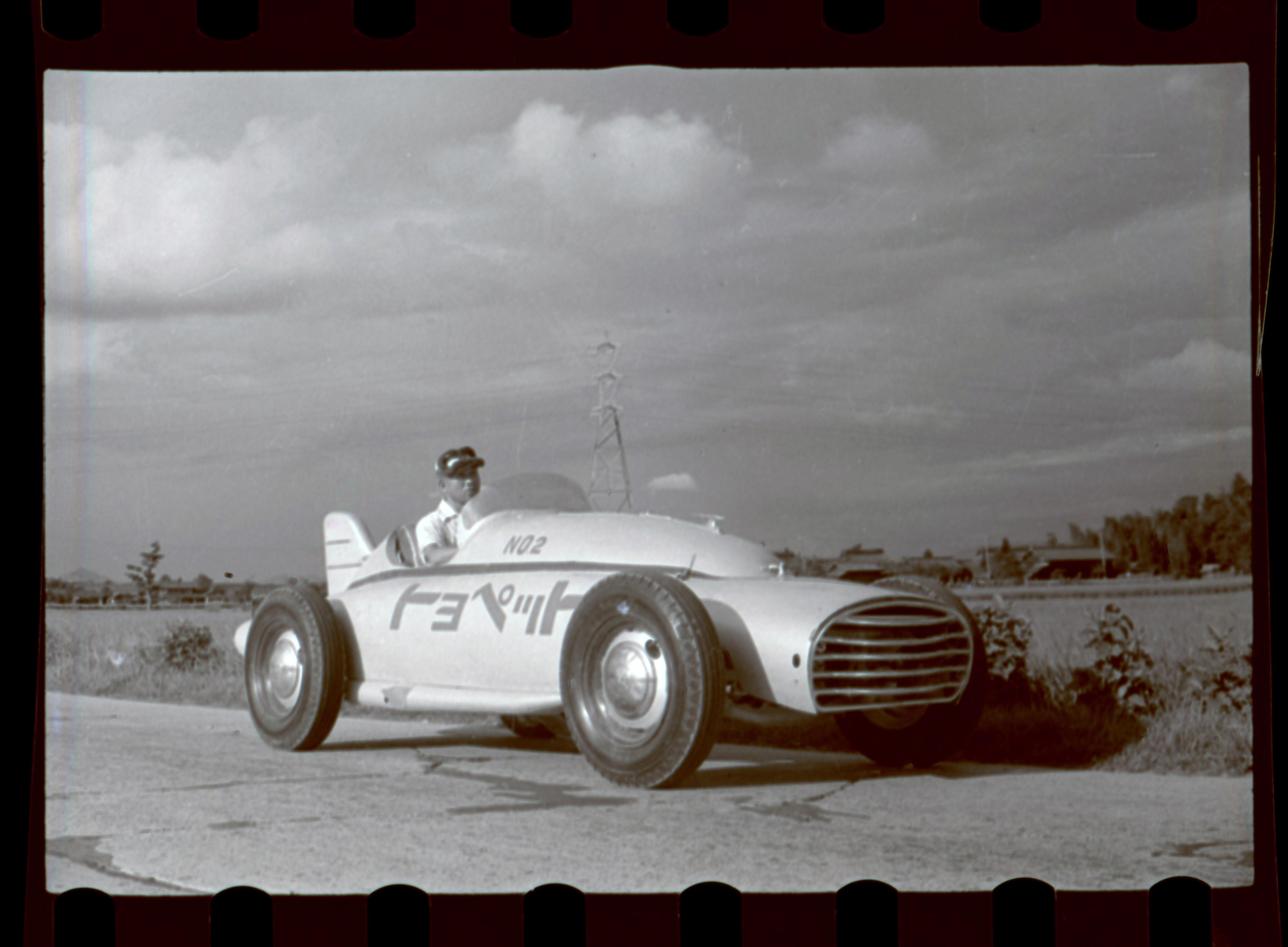

Only two Toyopet Racers were ever built in 1951, as a mark of founder Kiichiro Toyoda’s passionate ambitions for motorsport and the Japanese auto industry’s future. Even within Toyota, few people know of their existence.

These cigar-shaped racers can be seen as the origin of Toyota’s commitment to making ever-better cars, as pledged by Kiichiro’s grandson Akio Toyoda upon becoming president in January 2009. More than 70 years on from those first machines, the project team sought to rebuild one essentially from the ground up, based on a handful of surviving photographs and documents.

After a year of collective effort, assisted by various people inside the company and beyond, the project was finally completed in March 2022.

In hindsight, the project’s most ground-breaking aspect was the decision to use it as an opportunity to develop the young engineers who will shape Toyota’s future. By sticking to the original hand-crafted techniques wherever possible, the team also sought to understand the mindset of the car’s creators.

Thanks to involvement in various kinds of motorsport, Toyota is home to many veteran engineers skilled in building racing vehicles.

However, the 15-member project team assembled through a company-wide call for applicants and nominations consisted entirely of young employees in their 20s and 30s. On top of that, none had any prior experience in building such a machine. What they did have was a strong desire to make a car with their own hands.

What did these young engineers get out of the project? We asked the three leaders to share their thoughts.

The importance of not giving up

First up was Daichi Sugimoto, leader of the team responsible for the racer’s electrical components, as well as the suspension and related parts. He also served as a test driver. Normally, Sugimoto designs and develops car electrical systems at the E/E Architecture Development Division.

Like many of his fellow team members, Sugimoto knew little about the Toyopet Racer when he applied for the project, yet was eager to try his hand at building a car. Only once the project got underway did he realize, with some astonishment, just how difficult that would be.

Sugimoto

Working just once a week for about a year, we had to do everything from designing to fabricating and assembling a complete car. It wasn’t until we got going that it dawned on me: though certainly interesting, this a massive challenge.

Despite that, I was spurred on by the passionate ambition of Kiichiro Toyoda and the people who worked with him to create a car not just for Toyota, but for the future of Japan’s auto industry. That’s what drove me to do my best.

Even so, Sugimoto’s bread and butter is developing car electrical systems—with no experience designing, manufacturing, or assembling suspensions, he would have to start entirely from scratch.

Sugimoto

It was all new to me, completely unknown territory. I had to start at the beginning, learning and thinking for myself as I went.

In my regular work, I don’t have many opportunities where I can freely decide what I want to focus on, but the racer project allowed us to do just that. That’s why I was able to throw myself into the task and why I enjoyed it so much.

Engrossed in both his regular duties and the Toyopet Racer work, Sugimoto says that he may have overdone it at times. He reflects on an important lesson from the weekly sessions spent working with his team.

Sugimoto

No matter what, don’t lose heart at the outset. If you go in thinking you can’t do it, it’s game over. By staying the course and working together to figure things out, you can find a way.

For me, this mindset was the most important takeaway from the project.

Looking beyond my own responsibilities

Next, we spoke with Masashi Watanabe, who led the team that designed and produced the frame, body panels, seats, and driving position. Outside the project, he designs car bodies at the Body Technology Development Division.

Watanabe

I joined Toyota the year after the TV drama “Leaders” aired, depicting the struggles of company founder Kiichiro Toyoda, who conceived the Toyopet Racer, as he worked to develop domestic automobiles. I came here knowing that history.

I was stunned during this racer revival project to learn that Toyota’s carmaking was so far behind foreign manufacturers in those days.

I couldn't believe that our predecessors built Toyota into what it is today from that kind of start. As an engineer, for the first time I gained a deep understanding of the company’s history and technologies.

Watanabe admits that, on the technical side, the project didn’t provide much expertise that can be applied to his current work. Nonetheless, the process taught him a key lesson that he hadn’t encountered in his regular role.

Watanabe

When designing the body, I found myself constantly thinking about what had driven the people who originally created this machine, since I knew so little about how cars were made back then.

I became a little emotional when I was figuring out the driving position as I imagined how they must have felt. With no seatbelts or headlights, in a sense, they risked their lives on the test drive from Osaka to Tokyo. To me, that shows a degree of passion we don’t see today.

Responsibility for the machine’s various parts was divided during the project. And yet, Watanabe notes that he soon began looking beyond the scope of his own duties to the project as a whole.

Watanabe

There are certain parts of a project that cannot be divvied up, someone just has to do them. That’s one thing I came to notice.

I began to think, “This isn’t right—as a leader, I have to look at the project as a whole and work to ensure that everything goes well.”

I doubt I would have developed this perspective if not for this project. I see this as one of my main lessons, something that will continue to benefit my work going forward.