Edeson, created out of BE Creation, is a new business scheme from Toyota that has received many orders. It apparently all started when the project's creator witnessed his grandfather kneel down on the ground in apology before a client. What does this manufacturing support service from Toyota entail?

A service that acts as a go-between for clients and producers to define requirements

Among the issues in the Japanese manufacturing industry is the client's concern that producers will not make what they want to create.

Producers, meanwhile, often struggle with the fact that they are unable to make what the client wants in the first place due to unreasonable requests from startups and others who know nothing about manufacturing.

Many startups also change requirements frequently, which leads to the problems of losses and low profits when accommodating them.

The business model for Edeson is to act as a go-between for clients and producers and sort requirements for what the issues are and how they should be addressed.

Taken from the Edeson website (Japanese only)

Defining requirements is the basic service in Edeson, undertaken as a form of product management. Edeson has also launched a service where it acts as a consultant on improving factory operations for producers who want to lower costs.

Seeing his grandfather bow deeply sparks a win-win business model

Edeson's origin story traces back to the childhood of its creator, Yusuke Yokota. Yokota's grandfather ran a small factory that manufactured trestle stands to hold glass plates used in the construction industry.

Yusuke Yokota, Advanced Project Promotion Division/New Business Planning Division

When I was nine years old, I witnessed my grandfather kneel on the ground in apology before a client.

When I asked, “Why are you doing that?" he said, “I would do anything to protect my family,” but I found it shocking.

The experience made me wonder why people who work so hard are not properly recognized, and I began to think we should change the very structure of Japanese manufacturing.

After graduating from university, Yokota was offered the opportunity to take over his grandfather's company, but with a passionate desire to transform Japanese manufacturing, he joined Toyota Motor Corporation.

This was because the Toyota Production System, a system fundamentally aimed at improving society and the nation, along with its connections to various manufacturing companies and global operations, aligned with Yokota’s aspirations.

After joining Toyota, Yokota started in the Production Engineering Development Division (now the Production Engineering Development Management Division) and was in charge of production engineering development for in-house parts. His secondment to a parts manufacturer also served as a valuable experience. He bided his time and applied to the internal new business proposal system in May 2022. He and his companion Akira Nishida, then in the Purchasing Division, drafted a vision that has led them to this day.

Fostering open communication

One of the challenges in Japanese manufacturing is difficulty in cooperation between clients and manufacturers.

While not explicit, certain frameworks exist, and business practices make it difficult to go beyond these.

Yusuke Yokota, Advanced Project Promotion Division/New Business Planning Division

The existing model is able to provide a stable supply of high-quality products at low prices, but it also tends to make it difficult to move quickly when trying new parts and products.

Clients are also unable to disclose knowledge because it is confidential information, which is one reason startups struggle to find producers.

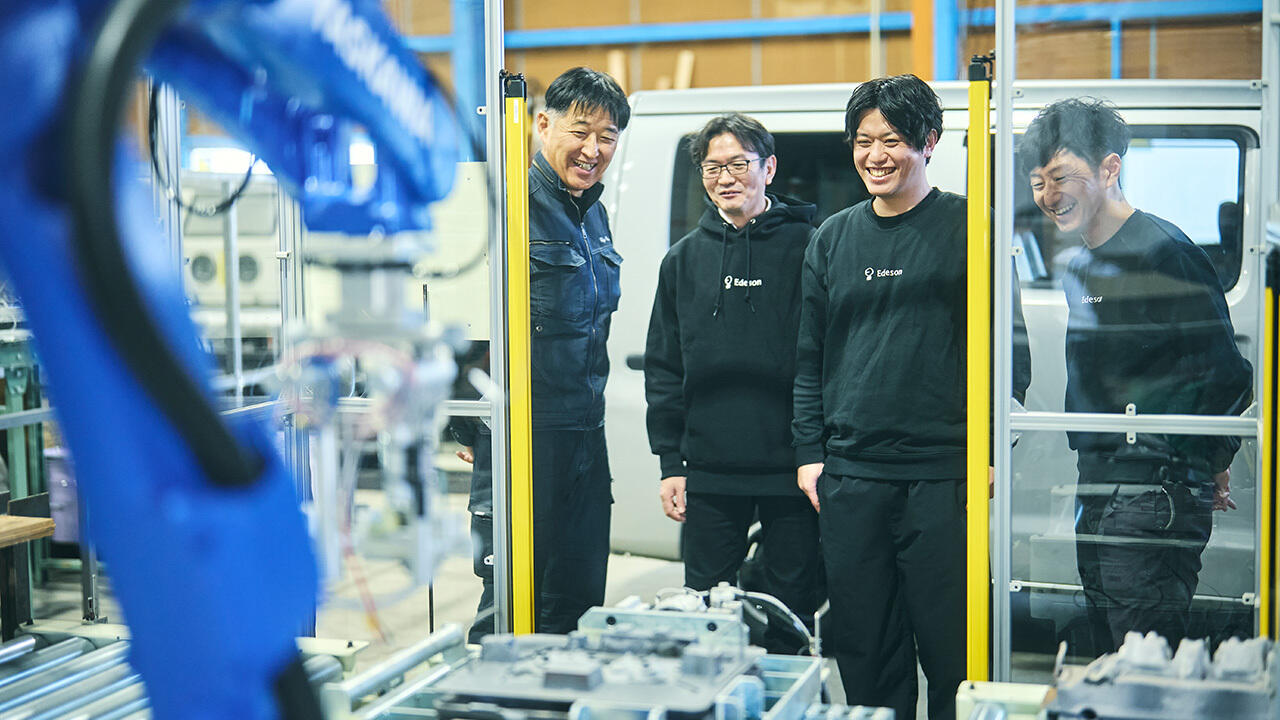

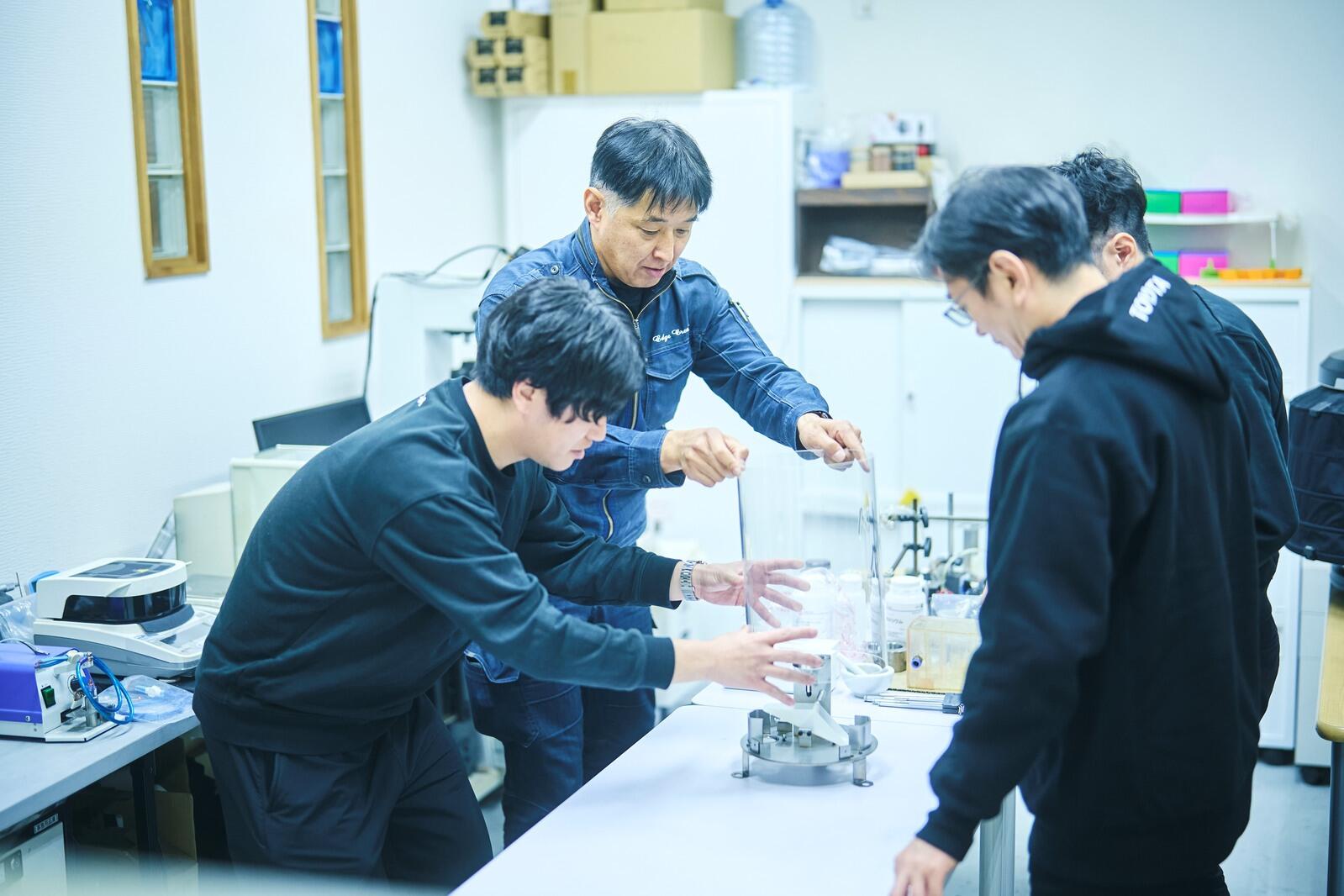

We also spoke with of Edge Creators, which has received orders from Edeson and works on several projects as a producer.

Edge Creators is not a mass production factory but a company that conducts experiments and assessments that leverage their expertise in metal casting, which is why it often serves as a subcontractor.

President Masashi Sakamoto of Edge Creators

What makes it difficult to talk to clients is that we have no opportunity to show our track record.

Matching through keywords alone doesn't really lead to work either if the client is unacquainted with products or parts.

For this reason, producers with new ideas often end up unable to properly explain them to clients.

What’s more, producers these days are often asked to think up concrete specifications as well.

Considering specifications takes a lot of time, and there have been cases in the past where, after specifications were disclosed, that knowledge was then stolen, and the product was produced at another factory.

The future of Japanese manufacturing lies in data created through trial and error

Yokota came to believe the underlying factor behind this was that money is paid only once goods are delivered.

Yusuke Yokota

The process and effort that goes into making products are undervalued. Producers read the room and purchase test equipment or new facilities before they are asked to do so. But if they don't receive orders, this only leads to debt. That is an issue as well.

What Yokota envisions for the future is a new business model that recognizes value not only in products but also in the processes and knowledge behind them.

He has conceptualized a system that uses a “network of cooperation” rooted in Japanese culture and spirit, where producers are paid for processes and even data on failures.

Yusuke Yokota

The more data you have on failures, the higher the probability of success.

Allowing failed cases to be purchased enables clients to allocate resources elsewhere.

A small team of people who love experiments could make a living through trial and error alone.

The logic behind Edeson is that it serves as an open platform to digitalize and share processes and failures, letting clients work efficiently on innovative product development without letting producers' everyday trial and error go to waste.

This results in creating opportunities for the Japanese culture of manufacturing, which excels at mastery. Investment in AI development for this has already begun.

A shared passion for revitalizing Japanese manufacturing

In Be Creation, the new business creation scheme at Toyota, Stage 1 involves a client interview to hear out all of the client's issues. It was here that Yokota met President Sakamoto of Edge Creators.

What Yokota and Sakamoto shared was a simple yet powerful desire to revitalize Japanese manufacturing.

President Masashi Sakamoto of Edge Creators

The Japanese manufacturing industry won't change unless we take on new challenges. This was something I could tell Yokota was serious about.

I thought that if Toyota is serious about this, then we should follow their lead. I want to support the Edeson system of acting as a go-between for clients and contractors, and I believe there are things we can do as well.

Currently, this knowledge and technical capability are being used to provide support for manufacturing across industry boundaries.

An example of this is a rain gauge, part of a project underway at Edge Creators to bring to life a request from the company RainTech to “build a more affordable rain gauge.”

Yokota's passion has drawn a steady stream of colleagues from within Toyota.

Hirota Tsuribe, Production Engineering Division

The Production Engineering Division handles in-house requests. Even at Toyota, not everyone is well-versed in manufacturing, meaning sometimes the demands are unreasonable. In this sense, we share the same challenges as Edeson, which is why I decided to join.

Fumitsugu Tsuru, New Business Planning Division

They reached out to me when I was wondering about my future career path, so I decided to give it a try. Since joining Toyota, I have experienced everything from cutting-edge powertrain development to transferring to mass production, so I would like to use my knowledge in development to help solve client issues.

Yokota serves not only as the leader of Edeson but also works in the BE Creation secretariat.

Yusuke Yokota, Advanced Project Promotion Division/New Business Planning Division

Edeson will hopefully serve as a new stage for people passionate about manufacturing.

Regardless of whether you are a Toyota insider or outsider, we'd like you to help us take the next step together.

The secretariat also provides full support for those attempting new business projects, so we'd love for people to take on new challenges.