This series showcases Toyota's research in non-automotive fields, and this time, a soccer robot stuns former members of Japan's national team!

Swapping the office for a soccer field

Soccer in the park. Despite appearances, the guys were hard at work.

The robot’s 18 motors could be moved in thousands of different configurations in simulations. To get to the bottom of what makes a good kick, the team gathered data from countless cycles of putting foot to ball.

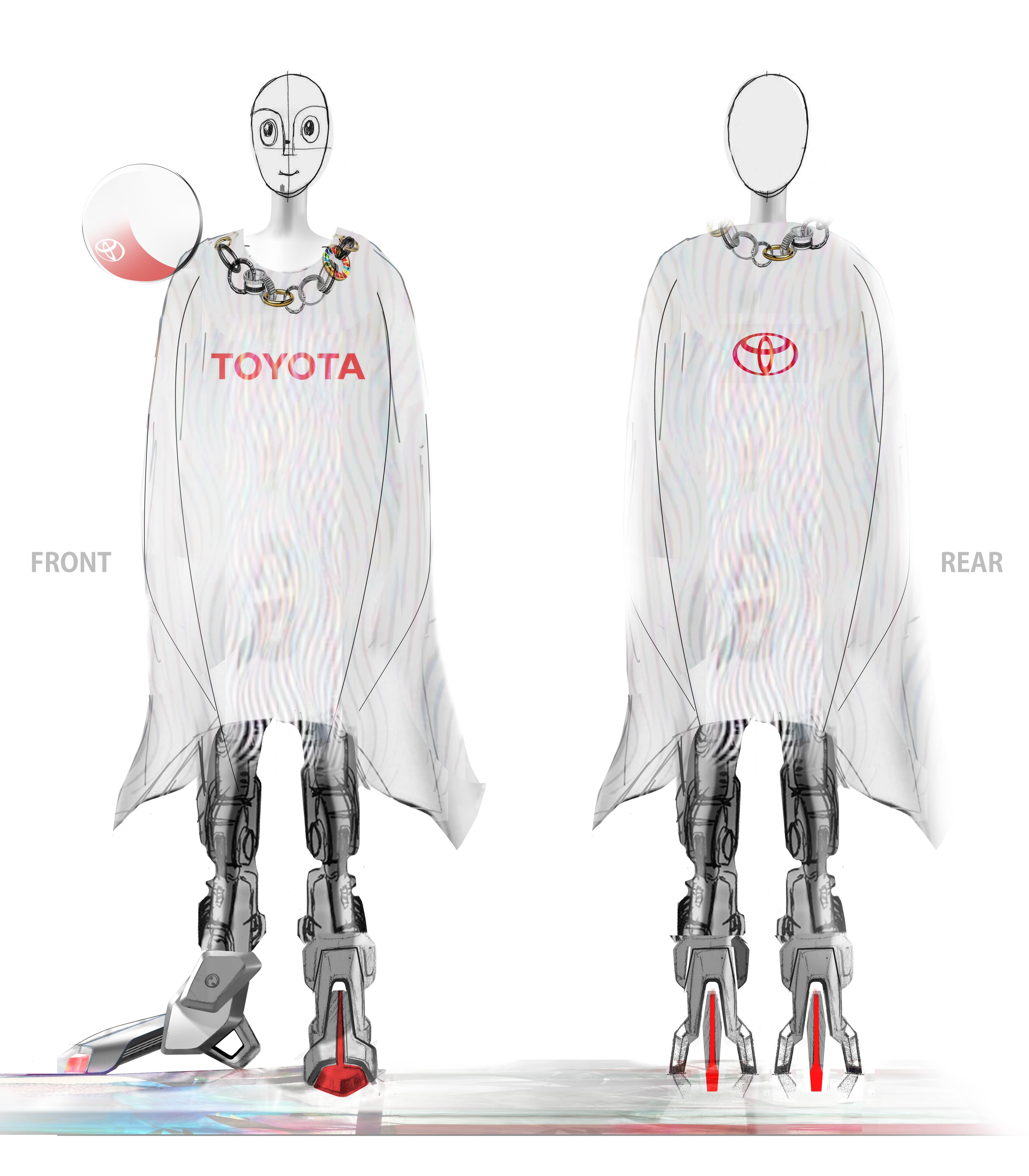

With sustainability in mind, the team also sourced reusable parts for the robot, including a cape made from airbag offcuts and a necklace of scrap bearings.

The development included aspects right in the carmaker’s wheelhouse, such as borrowing the sensor systems used in autonomous vehicles to help PIXI find its target.

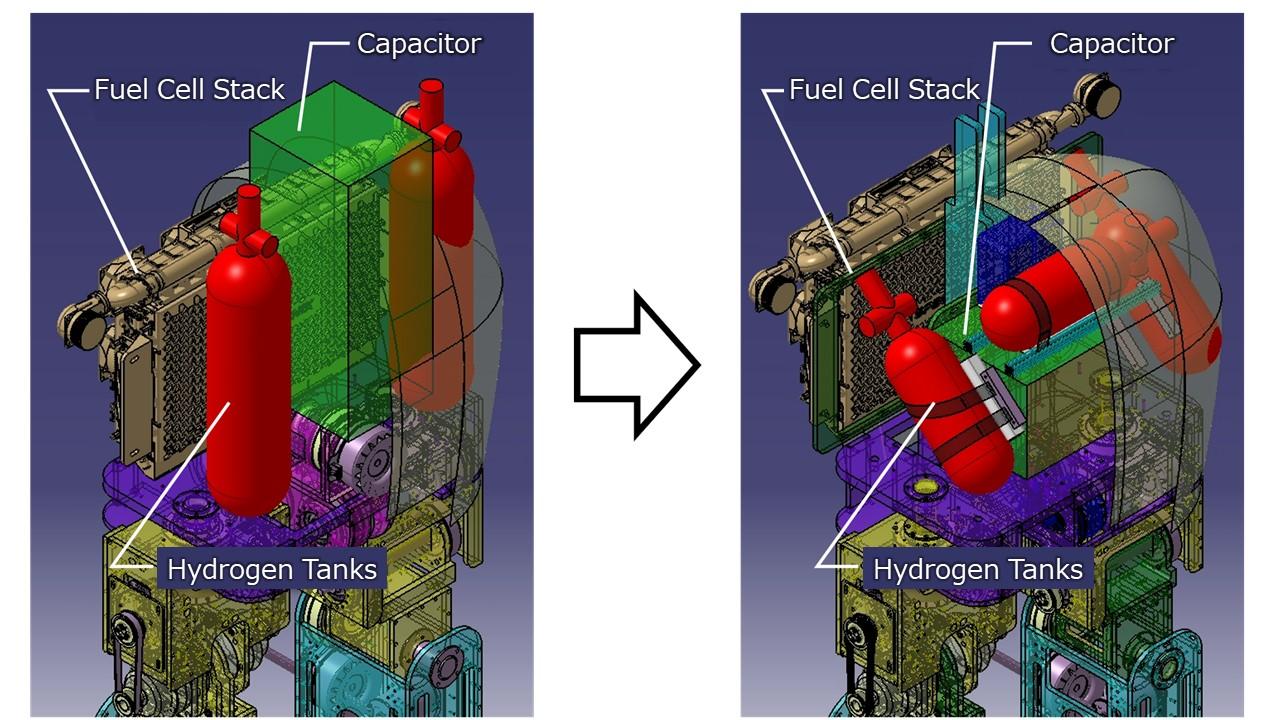

The need to accommodate hydrogen tanks and a power generator proved challenging on the design front, threatening to make the robot’s chest unnaturally bulky. “It’s going to look like a monster...” remarked one member, head in hands.

By pinning down PIXI’s exact energy needs, however, the team succeeded in making both the tanks and the generator more compact. Ahead of its first public outing, the robot took on a distinctly humanoid figure.

The shocking case of the broken neck

That debut performance would take place at Waku-Waku World, a joint Toyota City/TES event where children can experience the fun of monozukuri in the hope that they will become tomorrow’s engineers.

However, an incident on the eve of the big day rattled all those involved. During rehearsals, members discovered that the robot’s head was tilting at an awkward angle.

Miki

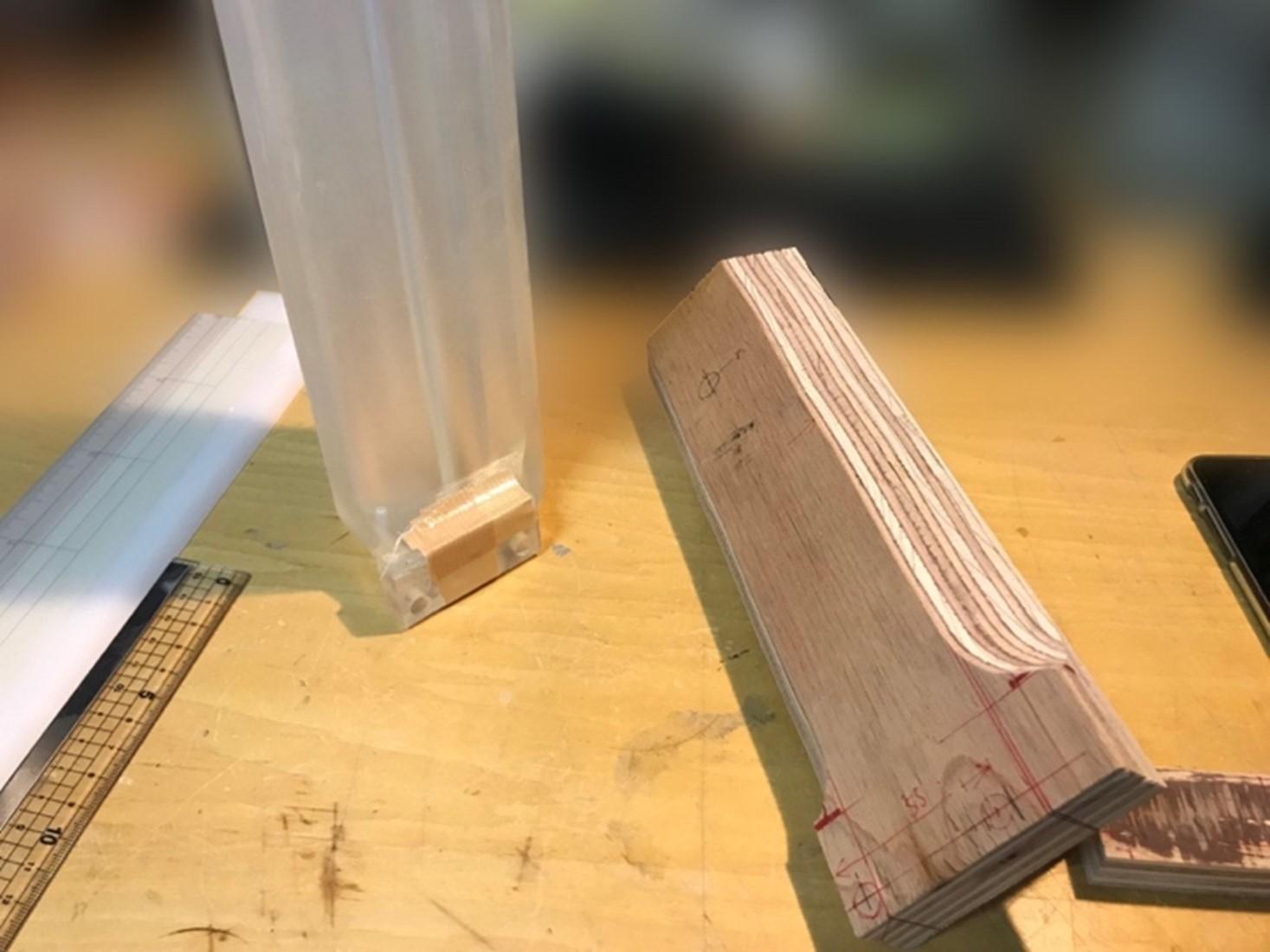

When we examined the robot, we found that the plastic neck bone had completely snapped. I was at a loss. Without time to 3D-print a replacement, it seemed like we’d have no choice but to go headless...

The team had just about given up by the next morning, but then a member brought in a wooden bone. He had made the piece by taking a saw to the wooden desk in his living room.

From there, PIXI underwent emergency surgery. With 20 minutes until showtime, it was finally repaired and ready to perform for the kids.

The day of the event drew some 300 children, who cheered loudly as PIXI scored its first goal. “Wow!” “You got it!”

Masaho Ishida, Assistant Manager,

Advanced Safety Technology Development Div.

Working at Toyota, we don’t often get to show the things we’ve created directly to customers, so this was a truly joyful moment. All of the troubles and setbacks we overcame made it that much sweeter.

The AI basketball robot CUE, previously showcased on Toyota Times, also started out as an independent research project at TES. It has since been approved as a company venture, with development ongoing.

The company provides the space, talent, and budget for teams to enjoy pouring their energies into researching non-automotive fields. It is in this environment that innovation flourishes.

After all, every machine, from automobiles to airplanes, began life as someone’s far-fetched dream. Toyota will continue pushing the boundaries of monozukuri to create exciting innovations that overturn the world’s perception of what is possible.