As a worldwide partner, Toyota supported Tokyo 2020 with not only vehicles but also a variety of robots. Toyota Times turns a spotlight on the autonomous field support robots (FSR) in the first part of the series featuring the tireless efforts behind the scenes of the Games.

One of the highlights of 2021 for people around the world and for Toyota would surely have been the Tokyo 2020 Games this summer.

As a worldwide partner of the Olympic and Paralympic Games, Toyota supported Tokyo 2020 with not only vehicles, but also a variety of robots. Toyota Times will present a three-part report on the tireless efforts of the project members behind the scenes of the Games.

Part 1 turns the spotlight on the project team behind the autonomous field support robots (FSRs) that supported the throwing events and rugby sevens.

Saving time and reducing workloads as much as possible

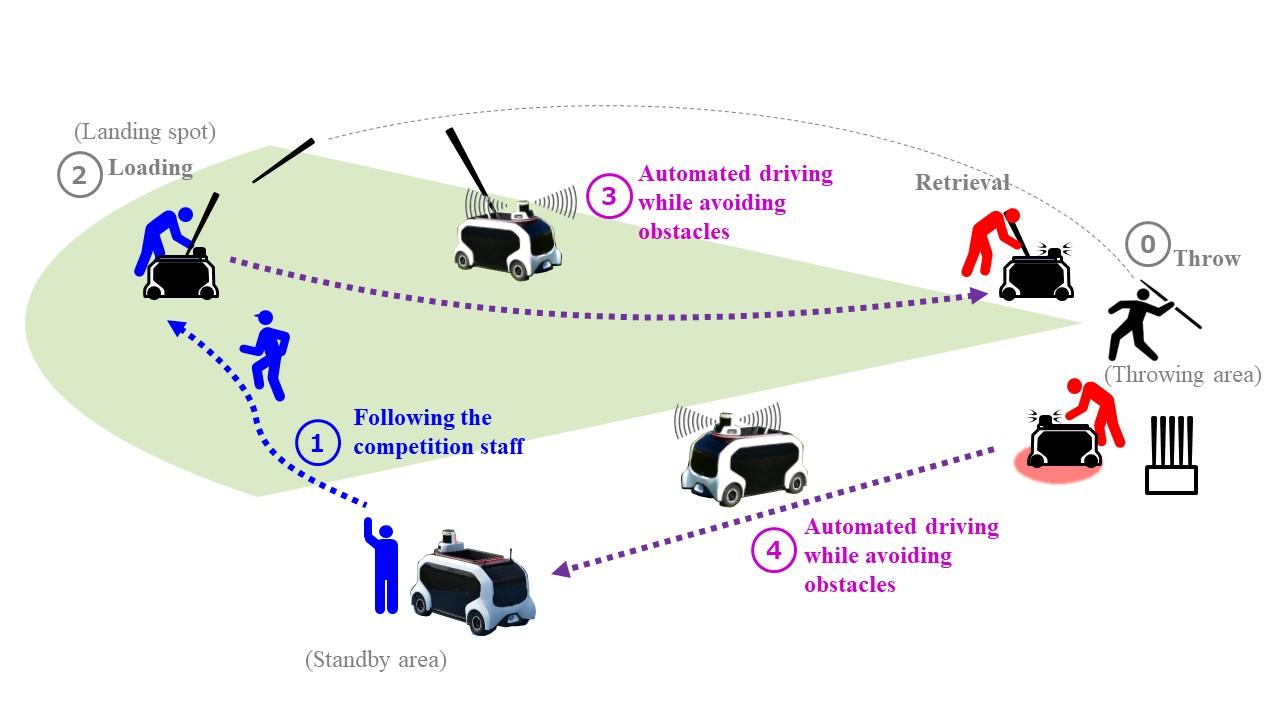

The FSR is an autonomous robot developed to support the retrieval and transportation of throwing objects such as hammers, javelins, and discuses in track and field throwing events.

FSRs were developed with two aims in mind. The first aim is to return throwing objects to athletes as quickly as possible, to create an environment where athletes can focus on competing. The second is reducing the workload of the support staff as much as possible.

Take, for example, the hammers used in the men’s hammer throw, which weigh 7.26 kg. Until the Olympic Games Rio 2016, the event staff had to carry the hammers from where they fell to the foul zone, a distance sometimes reaching 60 meters, and then return them to the athletes’ throwing area using a radio-controlled car. This series of actions was repeated every time an athlete threw an object. Performing such manual labor wearing a mask under the blazing midsummer sun in Japan would have been extremely taxing.

In addition, during the throwing events, a number of throwing objects have been prepared for the athletes. They may all look the same to the untrained eye, but some athletes only feel comfortable using one or two of them, and often wait for their preferred object to be retrieved after it has been thrown. Since the pre-event practice time is set at 30 minutes, the number of practice throws that can be performed depends on the FSRs’ performance. The best way to support athletes is to help them make as many throws as possible in the allotted time.

The project team considered the most important “athletes-first” tasks to be to reduce the workload of the event staff as much as possible and to return the thrown objects to their designated areas as quickly as possible. They therefore set the FSR’s nonnegotiable specs as being able to autonomously follow the movements of staff and work with them, and to choose the shortest routes without interfering with the event.

FSRs transported thrown objects instead of staff. In addition, the project team used the FSR’s autonomous driving ability for setting the ball in the center of the field before the kickoff for rugby sevens.

At Tokyo 2020, the FSRs provided support to 435 athletes competing in the throwing events and 58 rugby sevens matches. This was the first Games in which autonomous robots moved around the field with the event officials.

The full-fledged launch of the project was in April 2018, when Futoshi Ito of the Olympic & Paralympic Div. made a call for all interested employees to take part.

The hard work of a group of robotics amateurs

In 2015, it was decided that Toyota would be a worldwide partner for the Olympic and Paralympic Games through the Paris 2024 Games. Toyota established the Olympic & Paralympic Div. to plan the company’s efforts for the Tokyo 2020 Games.

At the same time, Ito was placed in charge of developing ways to provide support utilizing robots. Then, while watching the Rio 2016 Games onsite, Ito saw a radio-controlled support car moving around the throwing events field and decided right there and then that, “Four years from now, I want there to be a support car with the Toyota emblem operating on the field and I want to provide this support using Toyota’s robot technology, not radio-controlled cars.”

After this, he started making preparations with various internal and external groups with robotics skills, but it was difficult to gather members for the project due to the ongoing development of other robots. Therefore, in April 2018, Ito decided to recruit any interested employees from across the company to form a project team.

Three months after the start of the project, the core members were selected and the FSR development team was formed. However, the team was made up of engineers who were pretty much amateurs when it came to robotics. The team members quickly held a technical review meeting and began the development work by adapting the technology used in autonomous transport vehicles operating in factories.

It soon became clear that they would not be able to effectively utilize the technology they had envisioned out in a large field, because the conditions were different from those in a factory, where there are markers and a fixed route. Under these circumstances, they decided to solicit ideas from outside the company.

In response to this call, Department Manager Satsuki Yamane of the Robot & AI Development Dept. of Toyota Motor East Japan (TMEJ) proposed a plan utilizing AI technologies. In particular, those AI technologies for recognizing and avoiding objects with cameras, recognizing one’s own location, and making emergency stops were found to be essential for safe and accurate driving in the large field.

With the participation of TMEJ members gathered by Yamane, it became possible to start a demonstration test for a prototype vehicle in April 2019, one year after the project started.

Yamane

Compared to the final Tokyo 2020 model, the FSR model at the time was slower and less brisk in its operations. Figuratively speaking, it was like the robot was toddling. Still, we just about managed to achieve the basic operation of following behind the event staff, collecting the thrown objects, and coming back.

After the Games were postponed due to COVID-19, the team spent about two years repeatedly testing and making technical improvements to the FSR at throwing events across Japan. The members of the team, who had no knowledge of throwing events and were amateurs in the field of robotics, decided to “just get to know the field” and conducted a total of 11 demonstration tests.

The motto is “athletes first”

Takeshi Kuwabara, Project General Manager of CV Management Div., who served as the FSR project leader, highlighted one experience in particular as being important. He was referring to a demonstration test at a sports event held in the middle of 2019.

He was told by an athlete with a vision impairment that the sound of the vehicle running was scary. The sound was the rotation of the motor, which was much louder than a normal radio-controlled car. It had not bothered the development team members. However, for people with vision impairments, a sound from an unknown source that they do not hear in the field every day is frightening, and it disrupts their concentration.

The new challenge became to ensure not only the safe operation of the FSR, but also that it functions in a way that is mindful of the athletes and all other participants. The team immediately reviewed the gear design from scratch and took measures to reduce the running noise, such as applying sound-absorbing materials, which reduced the noise by about 10%.

Since then, the team has continued to make improvements to the FSR from an “athletes-first” perspective, such as conducting water and heat resistance evaluations to ensure that events can proceed without stopping in any weather conditions, as well as making improvements to tires and the driving control system to minimize damage to the turf and prevent harm to the athletes’ playing environment.

Having undergone repeated improvements, the FSRs fulfilled their roles at the long-awaited Olympic Games without any trouble at all. At the subsequent Paralympic Games, the team decided to take a different “athletes-first” approach compared to the Olympic Games.

The Paralympic seated throws prompted this. There is a specific rule for seated throws that says that there should be four minutes of practice before throwing.

Athletes must be strapped into their throwing frame before throwing, and this process, as well as the practice throws, must be completed within four minutes. Therefore, the sooner the athletes finish positioning themselves in the frame, the more time they have to practice. The longer it takes to get positioned, the less time they have to practice.

This is a crucial process that could result in a reduced number of throws not only in practice but also in the actual event. In Japan, there are fewer seated throwers, and this was a situation that the team did not realize during the demonstration tests.

Ito

The easiest thing to do would be to help athletes position themselves in the frame but that is not possible due to the rules. We decided that what we could do was to return the throwing objects as soon as possible.

For example, if a thrown object flew only 20 meters, it would be faster for the referees to run and retrieve it than for an FSR to retrieve it.

In that case, however, we would not be able to achieve our second goal of reducing the manual labor of event staff, but we discussed this with the referees with our “athletes-first” perspective and ultimately decided not to have the FSRs in operation.

After several rounds of trial and error, the project team decided not to have the FSRs in operation, which they had worked so hard to perfect. It was thought that there might be some objections to this decision among the team members, but there was, in fact, not a single one.

Meanwhile, a secret initiative for the Paralympic Games was also underway.

At the opening ceremony of the Paralympic Games, the message “#WeThe15” was communicated worldwide. As previously introduced in the Toyota Times Athletes Now, this is a global human rights campaign that aims to make visible the people with disabilities or possible disabilities with a number: 15% of the world’s population or 1.2 billion people.

When Yamane learned about this campaign at the opening ceremony, he discussed with the FSR development team what they could do to contribute. They decided to launch the “Car #15 Special Project” and updated the exterior of FSR no. 5 so that its sticker, which said “5” at the Olympic Games, became “15” at the Paralympic Games. Ito said, “Everyone in the team was for the idea. This was the most memorable episode from the project and proof that we were really united as one team for Tokyo 2020.”

During the Olympic Games, the development team members took an “athletes-first” approach and worked as engineers to improve the performance of the FSR. However, at the Paralympic Games, they naturally came to make decisions not as engineers, but as individual people who were trying to be mindful of the athletes and the spirit of the Paralympic Games.

From “nice-to-have” to “must-have”

Ito noted, “Initially, the FSR was considered a ‘nice-to-have.’” In the field, there are not only event officials, but also official timekeepers, measurement takers, and TV crews who have predetermined places where they want to set up measuring equipment and cameras to record athletes’ achievements and show them to viewers. These are all “must-haves” and the FSR, which was introduced to the field as a trial piece of equipment for athletic events, must not obstruct them.

At the same time, the development team wanted to maximize the role of the FSR in delivering the thrown objects to the athletes as quickly as possible. In order to achieve both goals, the team created a hand-drawn, optimal thrown object retrieval route map every day during pre-event preparations, and held numerous discussions with relevant onsite staff to prove that the FSR was based on an “athletes-first” concept.

At some point, the FSRs became fellow members of the event staff, entering and exiting the field together with them. The activities of the FSRs were shared on social media and reported on by traditional media around the world, with people commenting, “They’re working so hard and are so cute” and “They’re so advanced.”

Kuwabara

New world records were constantly being set at the Paralympic Games. One day, the FSRs were very successful in setting the optimal route, and the event itself went very smoothly and finished early.

At that time, a member of the event staff said to me, “Today’s the FSRs’ turn setting a world record.” I was so happy to know that people were seeing it that way, and I felt that the FSRs were really being accepted as fellow members of the event staff.

After the Games, one of the event staff said, “Thank you so much. We would have collapsed if it wasn’t for the FSRs.” The thoughts and efforts of the development team members bore fruit, and the FSRs became a “must-have” for the Games.

The “YOU perspective” deepened by being onsite

At Tokyo 2020, the team gained more than just a technology that was refined through repeated practical demonstrations.

Nishimura

The weight and feeling of our internal term “YOU perspective” is completely different before and after the Games. This is not just my feeling, but one shared by all the project members.

At Toyota, we often talk about the customer’s point of view, but our technology development members do not have many opportunities to actually talk to customers in their usual work.

For the FSR project, we did not know our customers at first, so we started by going onsite and trying to get to know what it’s like. We were able to finish the project by listening to the voices of our customers, who were the athletes, the event staff, and everyone else involved. I think this project embodied the customer’s perspective.

More than acquiring a new technology, the team members were able to experience the customer’s perspective, which is difficult to do in their normal work. On top of that, they were able to experience this in a project that they themselves volunteered to join. The members considered this factor significant.

There are plans to apply the FSR technology to robots that will help with logistics in TMEJ’s factories. “The younger members of the team had significantly different looks in their eyes before and after the Games. Now, they incorporate the customer’s perspective, cultivated through the FSR project, in their daily development work,” said Yamane.

Having truly learned the importance of the “YOU perspective” at Tokyo 2020, the development members have already taken on their next challenge.