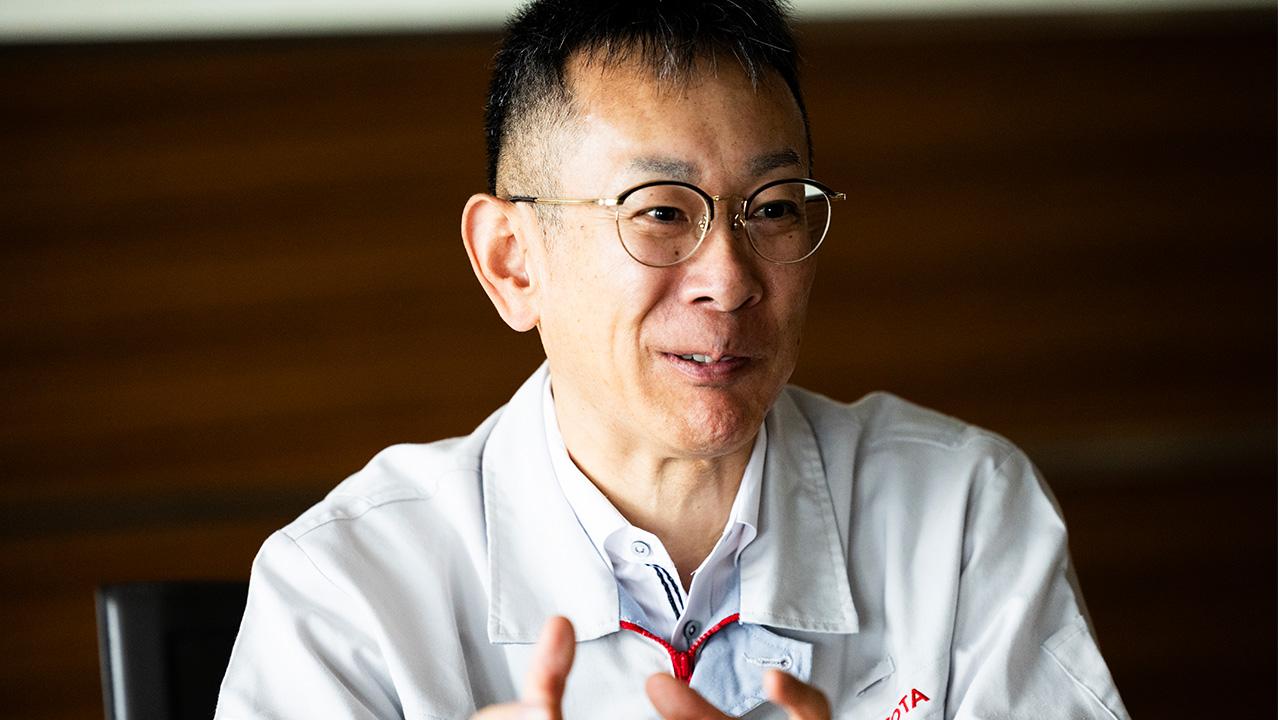

Automotive analyst Shinya Yamamoto has been going one-on-one with this year's trio of newly appointed presidents. In this second interview, BEV Factory President Takero Kato delves into his life as a "Toyota man."

Singlehandedly starting a BYD collaboration

In short, Takero Kato’s experience in various roles helped him become a body design specialist. Then, in 2018, he was shocked during a business trip to China.

For the first time, I came face to face with the competitiveness of Chinese components. In China, they were not simply learning and applying technologies, but also rapidly transforming manufacturing.

Laying eyes on equipment that I had never seen in Japan and their state-of-the-art manufacturing, I was struck by a sense of crisis—"We’re in trouble!” At the same time, I began to think that I would like to spend the rest of my career in China.

Though just a dream at the time, that chance came sooner than expected.

I then left body design to work under Vice President Shigeki Terashi (now Executive Fellow), planning the next-generation TNGA.

But on the first day in this new role, Terashi suddenly asked me, “Kato, can you wrap this job up in three months?”

As you can imagine, I tried to tell him I had just arrived that day, but he brushed my objections aside... In the end, I completed the job in three months, as instructed.

Then, two days out from the Golden Week holidays, I was unexpectedly called up to the top floor of the engineering offices.

In a room full of executives, Terashi told me, “We are thinking of doing a project with BYD. Can we ask you to handle it?”

I’m pretty sure the meeting lasted less than an hour, and I had no idea what was going on. My mind was full of question marks.

As it turned out, Kato had been picked to lead a project to jointly develop an electric vehicle with BYD.

When I asked Terashi who else was involved, he said, “Could you put together a team?” and I frantically got to work.

I may have been alone, but as the person in charge, I immediately contacted BYD’s Japanese arm and arranged to meet in Nagoya. We did so during a downpour in the middle of Golden Week.

Since this was a top-secret assignment, we introduced ourselves in my Prius on the top floor of the Nagoya Station parking lot. I explained the situation, and we got to work, computers on our laps, to plan a business trip together.

I didn’t have much information on their cars, so I was desperate to learn.

Then, after the holidays, I went to BYD headquarters. I met the head of the company, and of course, it was more than mere pleasantries. They had many questions: “What are you planning?” “What kind of car do you want to make?”

I kept thinking to myself, “I was only given this job a few days ago...” But I sketched up the packaging on the spot, and we discussed what I wanted to build.

When it mattered most, those sketching skills Kato had honed since childhood saved the day. In life, there’s no telling when something will come in handy.

I continued visiting the BYD headquarters, and we spent half a year laying the groundwork. Then, at the start of 2020, we decided on our concept. I put together a full car team, and we began development that July. In that first year, we had 45 members, with my trusted connections taking on leadership roles.

I started out with people from the Body Design Division, but also talked with engineering and production personnel I had gotten to know during my stint in Vehicle Structure Planning. We put together a big team.

Here too, Kato’s previous roles and networks were valuable assets.

The twists and turns of bZ3 development

So, what were Kato’s impressions after visiting BYD?

I already had a sense of the speed with which things are changing and technology is improving in China, so I was eager to get in there and soak up what we didn’t have to drive further development.

We all tackled the development together—BYD or Toyota, Chinese or Japanese, it didn’t matter. Since most were from BYD, the conversation tended to center around Japanese members, but we worked together entirely as equals.

From an outside perspective, Kato was the bZ3’s chief engineer, but the group had a flexible mentality.

In a way, we were like an anonymous organization. To boost both carmakers, we deliberately avoided creating a Toyota-style Z (product planning) unit.

In reality, the leaders and members of each section—body, chassis, interior, powertrain, electronic technologies, etc.—planned and developed things on their own.

In other words, they practiced the style of vehicle development long touted by Akio Toyoda: the genba makes decisions, but the leaders take responsibility. This transformed the carmaking process.

For the bZ3, our product development was marked by constant change. In the past, a vehicle’s specifications were finalized before we began developing. This time around, however, we made 13 major changes and many smaller ones after the process was already underway.

The first big change happened five months after we modified the vehicle’s height and wheelbase. The overall height was lowered by around 25 mm, so the underbody had to be entirely redone. In Japan, that would have brought the entire development to a standstill.

Regardless, everyone agreed on the change because we were committed to putting out a product that would make customers happy. Deep down, it seemed like a complete write-off, but we had to go for it. I made the final call.

Why did I do it? If the designers are all saying, “We’re in trouble,” I thought it was important to listen to them and bring everyone onto the same page: “We need to change this. Let’s all make it happen!”

I wanted the whole genba to share the same mindset and move forward together.

This is a prime example of the carmaker’s boundary-spanning perspective.