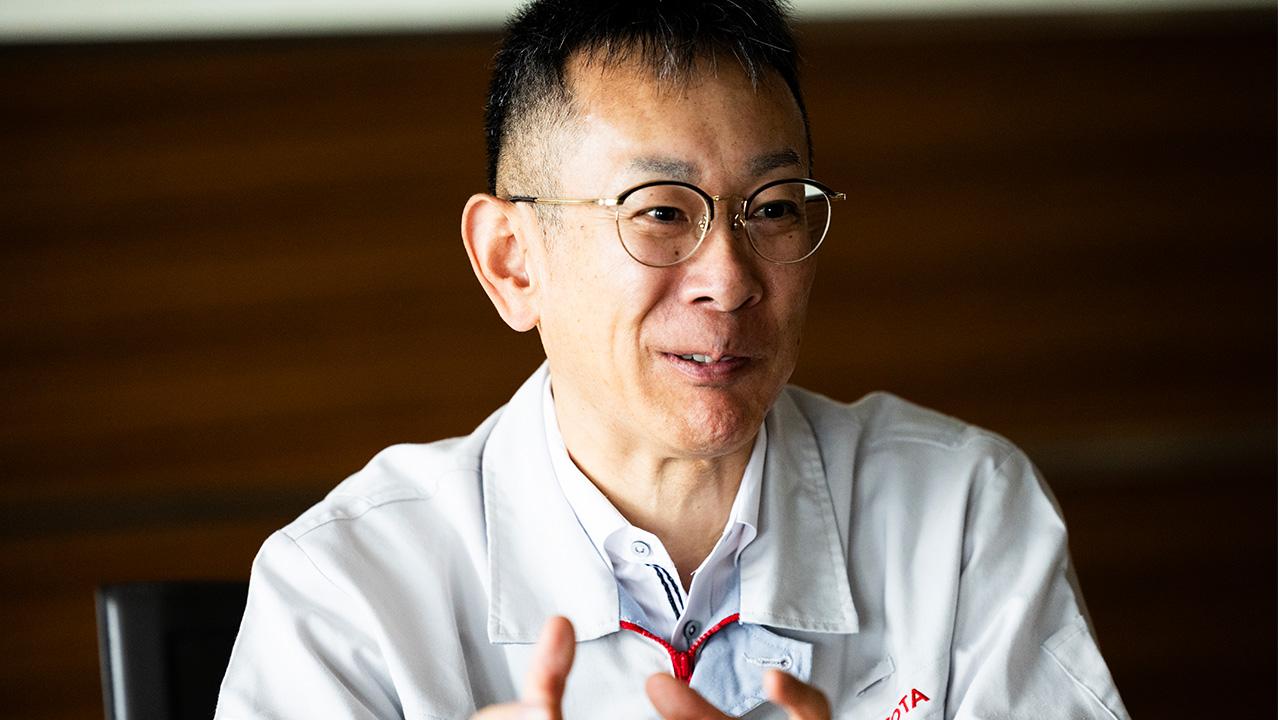

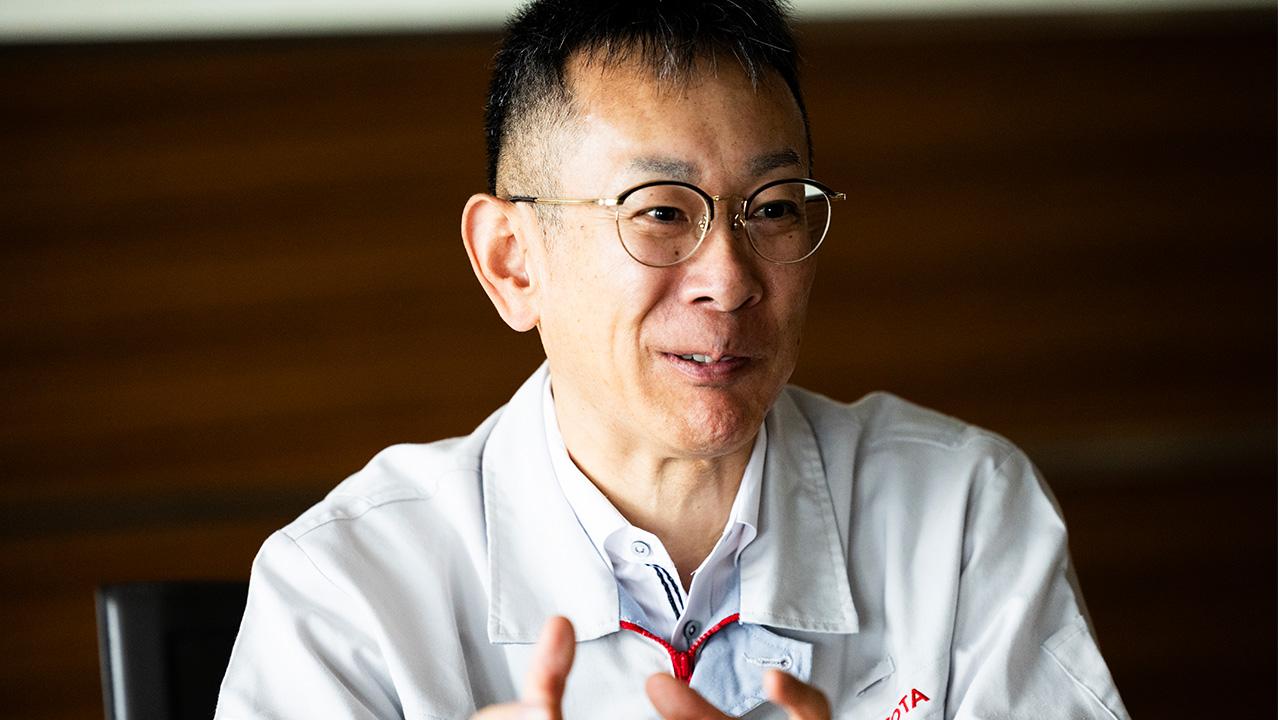

Automotive analyst Shinya Yamamoto has been going one-on-one with this year's trio of newly appointed presidents. In this second interview, BEV Factory President Takero Kato delves into his life as a "Toyota man."

In this second part of a three-part interview series, automotive analyst Shinya Yamamoto speaks with Takero Kato, President of the BEV Factory, which launched in May.

As with President Koji Sato, the discussion delved into Kato’s career, personality, and passion for cars.

What were the formative experiences that led to his self-professed love of BEVs? From the ups and downs of company life to being entrusted with a new organization, this interview is filled with stories you won’t read anywhere else.

An unusual career path—A reluctant student hits the books

(Text by Shinya Yamamoto)

At university, Kato enrolled in electronic engineering. With few transport options near home, he relied on a motorcycle to get around.

What was originally purchased as an everyday necessity soon captivated Kato. As he became more and more engrossed in the machine, his studies fell by the wayside...

And yet, Kato wasn’t the type of biker to tear noisily around town. Instead, he loved cruising down long, straight roads with the wind in his face.

I wanted to work with motorcycles in the future, but there were no job openings. And whatever was available went to the people with good grades first, so there was little left for me (laughs).

Part of me also wanted to return home (to Aichi Prefecture), and if you’re looking for a vehicle company in Aichi, it has to be Toyota.

With that, Kato somewhat begrudgingly joined the company. Despite majoring in electronics, he was assigned to the Body Design Division.

Actually, my first preference was the Design Division. I’ve always loved drawing and would often sketch.

However, according to the people in HR and senior staff, that wasn’t the place for me. So, if I couldn’t do that, I opted for body design to work on something visible.

But at first, I really struggled. I didn’t even know how a design drawing should look.

My first job did not involve car bodies but rather glass. I worked with suppliers to figure out whether laminated glass was better than tempered glass, and since the glass on cars is curved, what shapes were feasible.

But just like the body, I knew nothing about glass, so on the weekend, I went to the bookstore, bought a stack of glass-related books, and then studied.

Assigned to a role he knew nothing about, Kato overcame his aversion to study and began to hit the books in earnest. This effort soon paid off, as he was entrusted with all kinds of projects and tasks.

One particularly memorable assignment was in interior design, just as side impact assessment standards were first brought in. To work out the door trim shape, we focused on the body's anatomy, studying how humans move during collisions to decide where to position impact-absorbing material.

Actually, the electronic engineering faculty at my university was a bit unusual, and I had a professor with a background in speech and medical science. We studied human beings, for example, using x-ray images taken from the side of a speaking person to examine tongue speed and movement. I couldn’t believe that those experiences proved useful in design.

Into production—Lost in technology translation

In 2009, after 20 years in body design, Kato’s career took a new direction with his transfer to the production-side Project Planning & Management Division.

The role involved managing not only vehicle development schedules, but also preparations for the production that followed. Here, the key was understanding the technologies involved and figuring out how to make the work schedule flow.

Having specialized in car bodies up to this point, Kato now learned how the company worked as a whole.

Until then, I had only spoken with members of the engineering departments, and now I met the production team for the first time. Initially, I struggled with the technical terms. When I mentioned part names that were commonplace in engineering, they looked at me like, “What on earth is that?”

To get around that, I always tried to explain what role a part played. Looking back, I was something like a translator between engineering and production.

In 2011, Kato was transferred again to the Vehicle Structure Planning Division. This obscure-sounding unit was engaged in advanced development for the Toyota New Global Architecture (TNGA).

In a sense, Kato had come full circle, returning to a role that would make the most of his body design experience, but this time turned out slightly different.

Although I had specialized in body-related work, now, learning under the veteran Kiyohito Morimoto, I began looking at where the body fits into the car as a whole.

In creating the body packaging, I came to understand how elements such as rigidity, mass distribution, and tire characteristics affect the resulting car.

From there, I returned to my old haunt at the Body Design Division, where I was involved in planning and developing all TNGA platforms.