Akio Toyoda represented four automobile manufacturers associations to share how the auto industry in Japan is committed to responding to the COVID-19 crisis.

Other activities to support healthcare worksites

While not directly related to human life, there are other things we may do that can help support the frontlines of the healthcare system.

We see needs such as “providing vehicles necessary for transporting patients,” “vehicle modifications to support patient transport,” and the production of “bed parts for use in hospitals among other parts,” that we can also make efforts in.

By offering our help in areas that relate to our expertise and that can utilize our existing assets, we hope we can play our part and do something useful for everyone.

Understand the situation at the frontlines (efforts by the airport rental car services desk)

Please let me mention one more thing our “friends,” or partners, are working hard on. One example is at the airport rental car services desk.

Those people who are returning from overseas, after passing the medical inspection, are finding that they need to return home using personal vehicles as a way to prevent others from becoming infected.

There are many people visiting the airport car rental desk every day.

However, we have not been able to distribute personal protective gear to those working at the desk, and many of them are only wearing masks as they work.

Despite the fear of potential infection, they work hard for their customers every day.

We want to provide personal protective gear for each and every one of them, and so we continue to try our best to see how we might be able to do so.

Now, worksites everywhere are facing unprecedented situations. It is of utmost importance to grasp what is happening at the front lines as fast as we can, and, for now, under this situation, think of what we can do and act on now.

The economy is also in crisis

The economy is also in a crisis.

Until recently, there was a total global GDP of 9000 trillion yen; however, this has decreased by 15 to 20 percent within the last three months.

Economic measures to counter this situation are being implemented in each country and region. This is also true for Japan, where an emergency economic measure of 108 trillion yen was announced. Please let me take this opportunity to thank the government of Japan for deciding so quickly on what may be one of the biggest measures they have taken.

However, we are still facing an extremely tough situation.

The day will come when humans will conquer the threat of COVID-19. However, if the current situation continues, the economy in Japan may be exhausted. It may not even be possible to find a way to tackle COVID-19 fully before the economy is in ruin.

It is our hope as the automotive industry that we can be a part of efforts to prevent this collapse from happening.

Ripple effect of the automotive industry

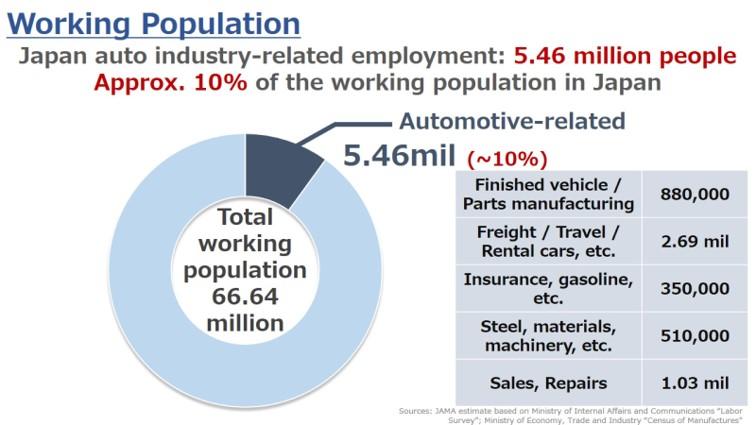

In the automotive industry there are approximately 5.5 million workers. This makes up approximately ten percent of the working population in Japan.

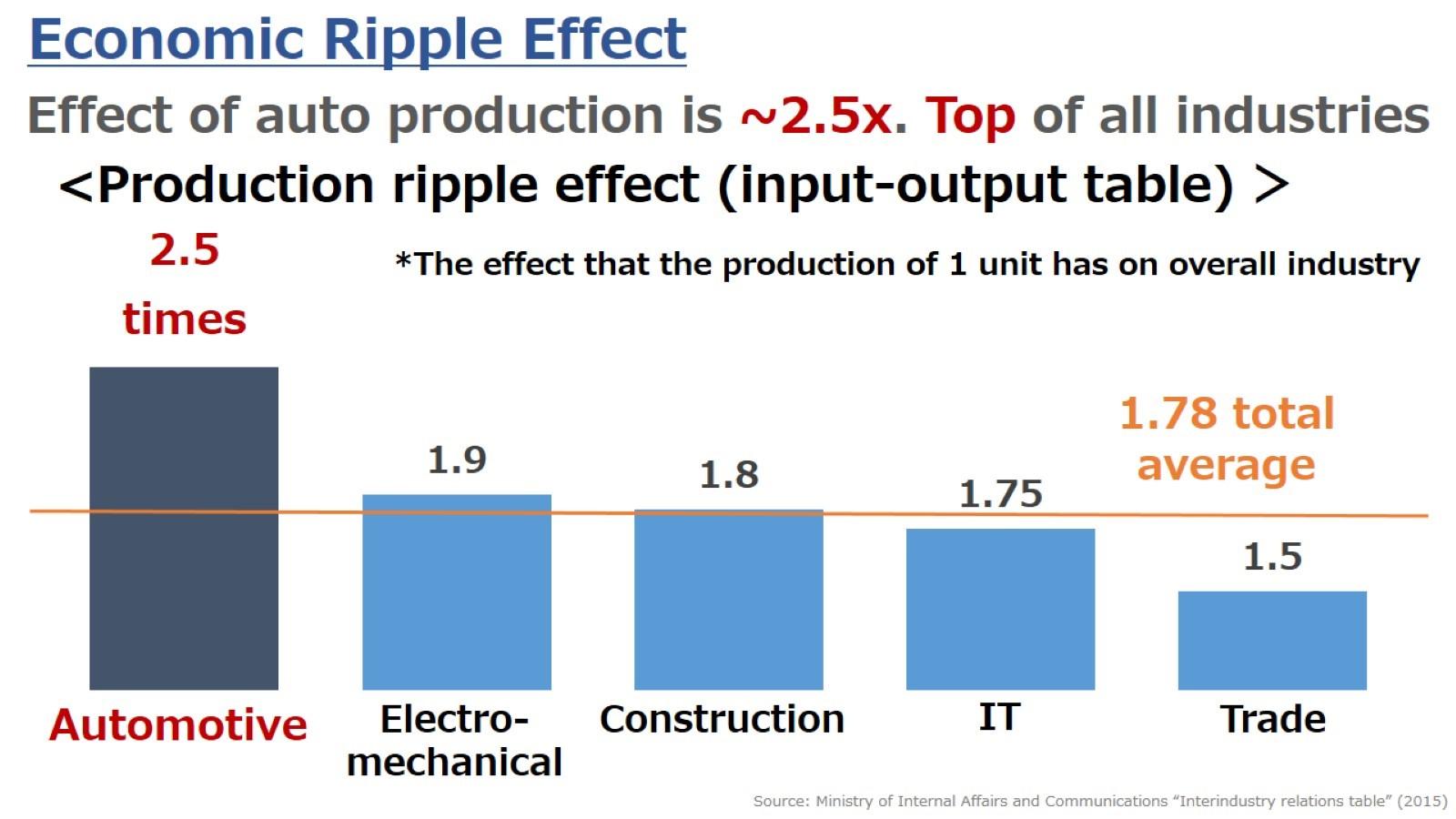

The automotive industry has a profound amount of influence that could cause a ripple effect to other industries. When we try to put a figure to it, the estimated effect the industry has on production is said to be “2.5 times” the amount.

This means that when the automotive industry produces “1”, this will lead to a production of “2.5 times the amount” across the world, making the automotive industry one of the top level industries in Japan (and the world).

We will make every effort to continue to stimulate the economy, and more than anything, we understand that protecting employment is a powerful force to help stop the collapse of the economy.

Therefore, we will do our best to keep our businesses in operation.

To do that, first we need to protect workers related to the automobile industry from becoming infected. So it is really critical that we take thorough measures to prevent this. Furthermore, this is also important to help prevent the healthcare systems from collapsing.

Things we discovered (and left as assets for people to follow and use) by not giving up on domestic production

We have been through a lot, such as the Lehman shock and the 2011 Great East Japan Earthquake that occurred after that. During these difficult times, I was very insistent about retaining our domestic production.

With regard to this, a lot of criticism was received, some stating that from the perspective of economic rationality, it is wrong to stay focused on Japan (in terms of production).

After the earthquake and tsunami disaster, I believed that offering only temporary support would not be effective for a “true recovery” of the Tohoku region, so we built a new automobile body manufacturing company in the area and also a school that teaches monozukuri (making things).

This effort aimed at providing the type of long term recovery support needed to establish the roots of “making cars” there.

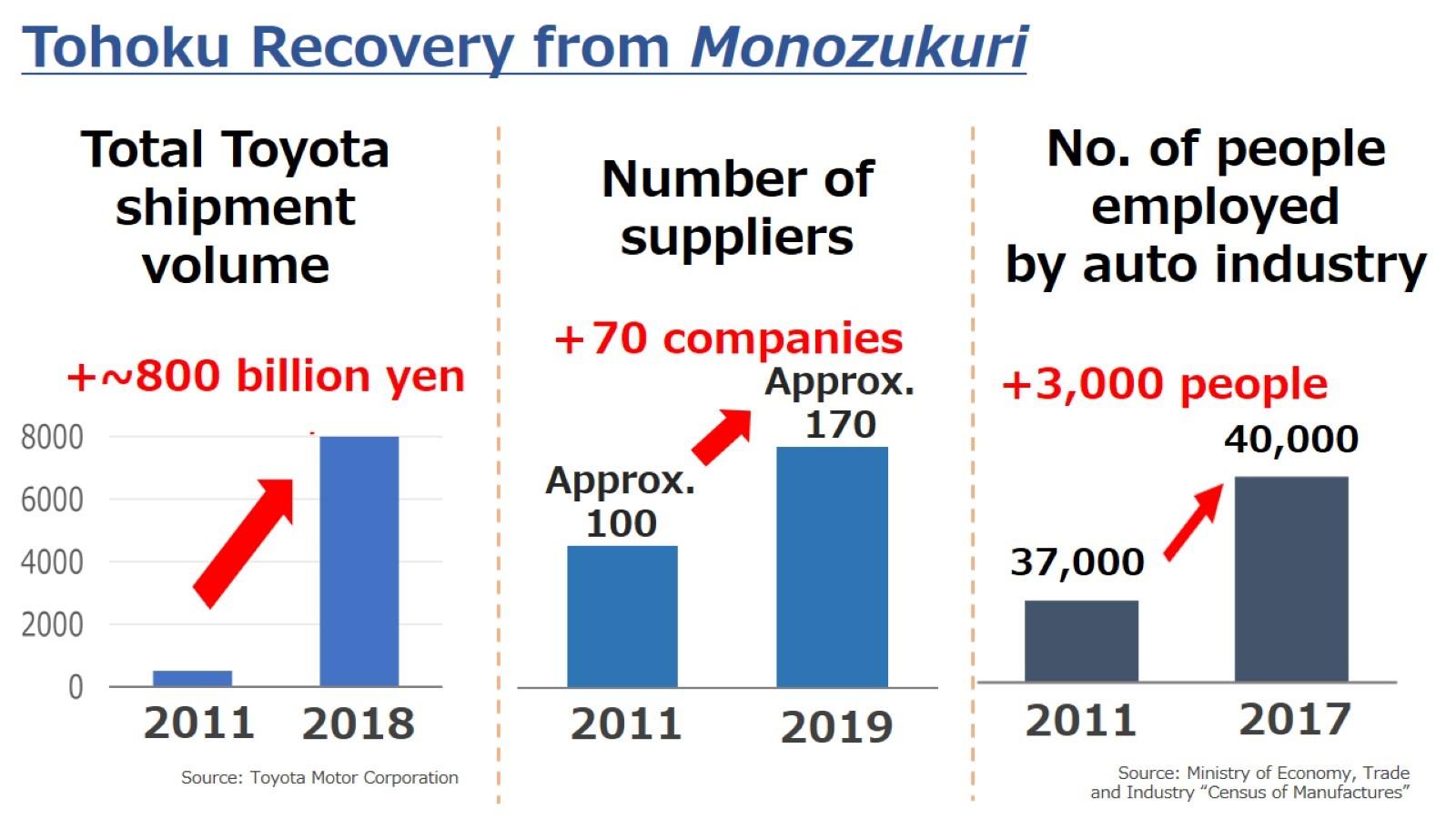

When we look at the Tohoku region now, nine years on from the disaster, the total value of vehicle which was 50 billion yen at the time, has now reached 800 billion yen, which is 16 times that amount. Furthermore, the number of suppliers mostly consisting of auto parts manufacturers which was approximately 100 companies at the time has now increased to 170 companies. Although there is high inflow and outflow of people in the Tohoku region, we have been able to increase the number of workers in the automotive industry there by 3,000 people. This current status in the Tohoku region was realized because the four associations here today worked together as one to conduct recovery efforts in the Tohoku region.

More than anything, new technology and skills are being created in the Tohoku region. These skills will be passed on; the people who learn these skills will teach this to the next person.

And they themselves will create a place where they can work, maintain, and develop themselves. At the time following the disaster, I made a strong commitment to myself that I wanted to establish Japanese monozukuri there, and was very focused on domestic production, and I don’t think this was a mistake.