A special feature looking back on Akio Toyoda's 14 years as Toyota's 11th president. Part two traces the changes reflected in the figures.

TPS and cost reductions strengthen structure

Looking back on his time as president, Akio often described it as “a fight to bring back what makes us Toyota.”

When talking about the company’s essence, the Toyota Production System (TPS) and cost reductions are among the first elements that come to mind.

TPS is Toyota’s management philosophy of “completely eliminating all waste in order to deliver quality products at reasonable prices and in a timely manner.” Here “deliver” refers to serving not only car buyers, but also those involved in the downstream processes of vehicle production.

The Toyota Production System is based on two pillars: “jidoka” and the “Just-in-Time” concept.

Jidoka is not simply automation, but automation with a human touch. The underlying idea is to eliminate waste, inconsistencies, and unreasonable requirements through human ingenuity, building quality and productivity into processes and ensuring that people are not just left to watch over machines.

Meanwhile, Just-in-Time is about minimizing lead times and “making only what is needed, when it is needed, and in the amount needed."

Underpinned by the jidoka and Just-in-Time concepts, TPS is the source of Toyota’s cost reductions and competitive strength, and one of the company’s core competencies.

The Toyota Production System, or TPS, and our approach to cost reduction are Toyota's true values.

One of the basic principles of TPS is "to reduce costs rather than operate on a cost basis." This means that, rather than setting prices by adding reasonable profit to cost, the only thing that we can do is lower costs, based on the key premise that sales prices are determined by the market, in other words, by our customers.

Keeping an eye on costs means keeping an eye on what we do. Each and every person, armed with an awareness of costs and a grasp of current market levels, must thoroughly eliminate waste in their daily actions. What used to be the norm had somewhere along the way ceased to be so. Realizing this has led to a new start.

In all workplaces, there is a call to action to fundamentally review fixed costs. We have begun steady cost-reduction efforts in which each and every cost, whether it relates to daily tasks or large events or projects, is being scrutinized, with everyone thinking about what elements actually represent waste.

…

With a strong determination to avoid "a losing streak," I believe that the accumulated results of steady, earnest, and thorough cost-reduction efforts, involving everyone, have begun to steadily become apparent in our financial results little by little.

As such, to sum up our latest financial results in my own words, I would like to suggest that they are results in which the true character of Toyota’s endless continuous improvement is starting to be reflected.

(Speech during announcement of results for 2017 fiscal year, May 2018)

When presenting Toyota’s results for the 2017 fiscal year, this is how Akio described the effect of TPS and cost reductions becoming widespread. His words were backed up by the numbers: the contribution of “cost improvement efforts” nearly doubled after Akio became president, from an average of 162.5 billion yen in fiscal 2001-2008 to approximately 318.3 billion between fiscal 2009 and 2017.

Product- and region-centered approach improves break-even point

When Akio accepted the top job, he placed “making ever-better cars” at the heart of efforts to revive the company’s business. As outlined in the first part of this series, he took concrete steps toward realizing this vision with the introduction of the Toyota New Global Architecture (TNGA) in 2012 and the in-house company system in 2016.

As these measures strengthened Toyota’s products, overseas the company focused on localizing the production and supply of cars tailored to regional needs, such as the Tundra in North America and the IMV series that originated in Thailand.

The IMV project had been spearheaded by Akio during his days as vice president. Aiming to “offer more-attractive and more-affordable products to customers worldwide at the same time,” the project helped to expand Toyota’s share of sales in emerging markets.

At the previously mentioned global policy briefing in 2009, Akio also commented: “In recent years, Toyota has been overly focused on making cars for major constituencies in the name of creating global models… Moving forward, I would like to offer people in each region products that are ideally suited to their local needs.”

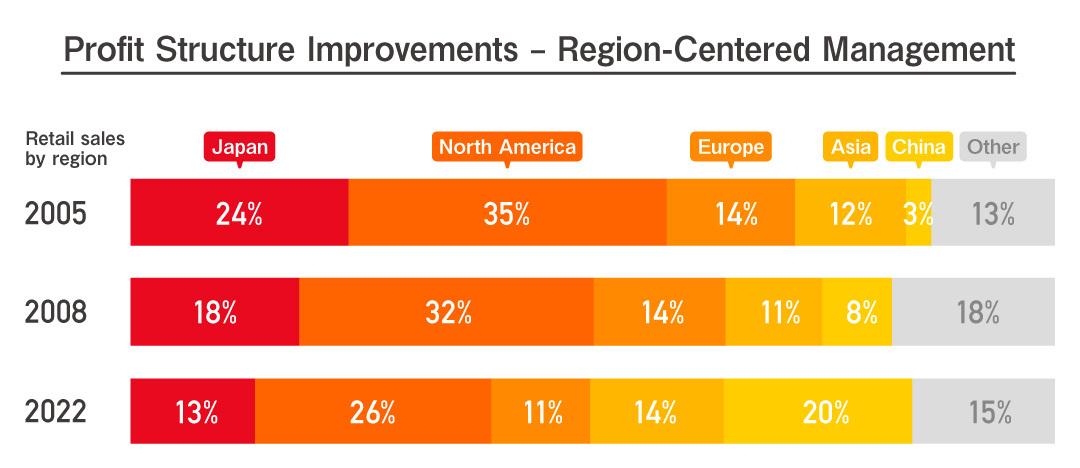

The change is visible in the share of sales by region. Whereas Japan and North America accounted for about 60% of vehicles sold in 2005, by 2022, the figure was around 40%. Over the same period, China grew from 3% to 20% and Asia from 12% to 14%. A business that once relied on sales in Japan and America has shifted to a more globally-balanced composition.

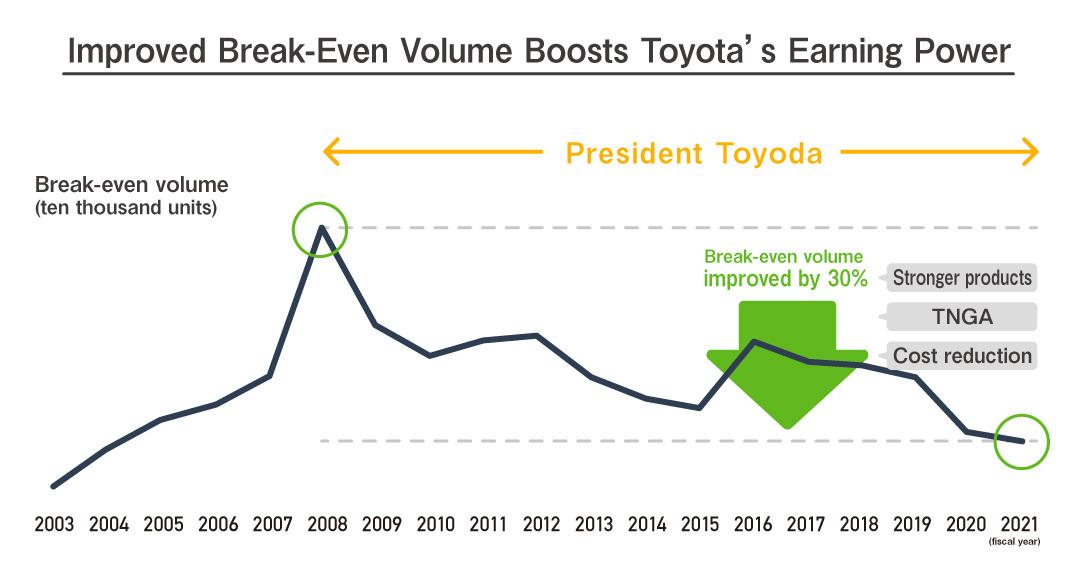

In this way, Akio’s introduction of the TNGA and in-house company system enabled Toyota to create high-quality cars with greater development efficiency. Leveraging these carmaking foundations to achieve balanced sales of regionally-focused products, the company improved its break-even volume by some 30% compared to the days of the Global Financial Crisis.

The general shareholders’ meeting in 2020 was held amid a pandemic-induced global economic downturn. There, Akio described how, since the financial crisis, Toyota had grown into a company resilient to external shocks.

I have often been asked: “Are you succeeding in strengthening your corporate composition?” To which, I have replied: “I will only be able to answer that question when we face another crisis similar in scale to that of the Global Financial Crisis.”

Now, with the spread of COVID-19, the world is facing a crisis of even greater proportions.

…

Now, I am able to confidently say:

“I firmly believe Toyota has grown stronger. It is my wish to use this strength to help those outside the company.”

(General shareholders’ meeting, June 2020)