Two Syrian students became interns at Toyota while studying for MBAs in Japan. What was their takeaway from the experience?

Toyota: a familiar presence in the Middle East

The history of Toyota in the Middle East goes back many years. Since starting a business in Kuwait in 1954, Toyota currently has locally funded dealers in 16 countries in the Middle East and Central Asia.

Thanks to popular large models like the Land Cruiser and Hilux, Toyota leads the region’s automobile market.

That is the area that the two interns came from.

- Why did you apply for an internship at Toyota? What kind of image did you have of the company?

Ahmed

My father drove a Corolla, and there were many Land Cruisers at the oil drilling site where I worked, so Toyota was a familiar brand.

Oil drilling sites are on the edge of the desert. In that kind of environment, the Land Cruiser is an indispensable partner that ensures your safety. I myself am a big Land Cruiser fan.

Toyota is known all over the world. I thought gaining experience at a global company like Toyota would allow me to learn a lot and hone my skills.

Everyone’s heard of the Toyota Production System (TPS), especially if you’re an engineer. You minimize waste and excess inventory. TPS applies to all industries, so that’s what I wanted to learn more about.

Ibrahim

My father was also involved in the petroleum industry, and he used a Land Cruiser. Everyone else around us also saw Toyota as being the car to own. They’re seen as being durable and reliable.

One of the reasons I came to Japan was because I wanted to learn more about Toyota and TPS, which I studied at university. I was really excited when I found out about this internship because I thought I’d finally be able to talk directly to someone at Toyota.

I only had to write one page to explain the reason for my application, but no matter how hard I tried, I just couldn’t condense everything into less than two pages. That’s how excited I was about jumping on this opportunity, no matter what it took.

What the two men learned at Toyota

Most of the internship was carried out online. They learned about TPS and TBP (Toyota Business Practice: Toyota’s eight steps to solve problems) among others through lectures, but they also visited a Toyota dealer and plant.

- What in particular left a lasting impression, and what all did you learn during your internship? Moreover, how did your view of Toyota change during this time?

Ahmed

In addition to TPS, I learned about the steps taken to implement TBP, which I thought was extremely useful for solving problems. It allows you to dig deep in your search for root causes, then you implement countermeasures. That sets a standard for other divisions and workplaces to follow.

These unique and outstanding methods were the most valuable takeaways for me during my internship.

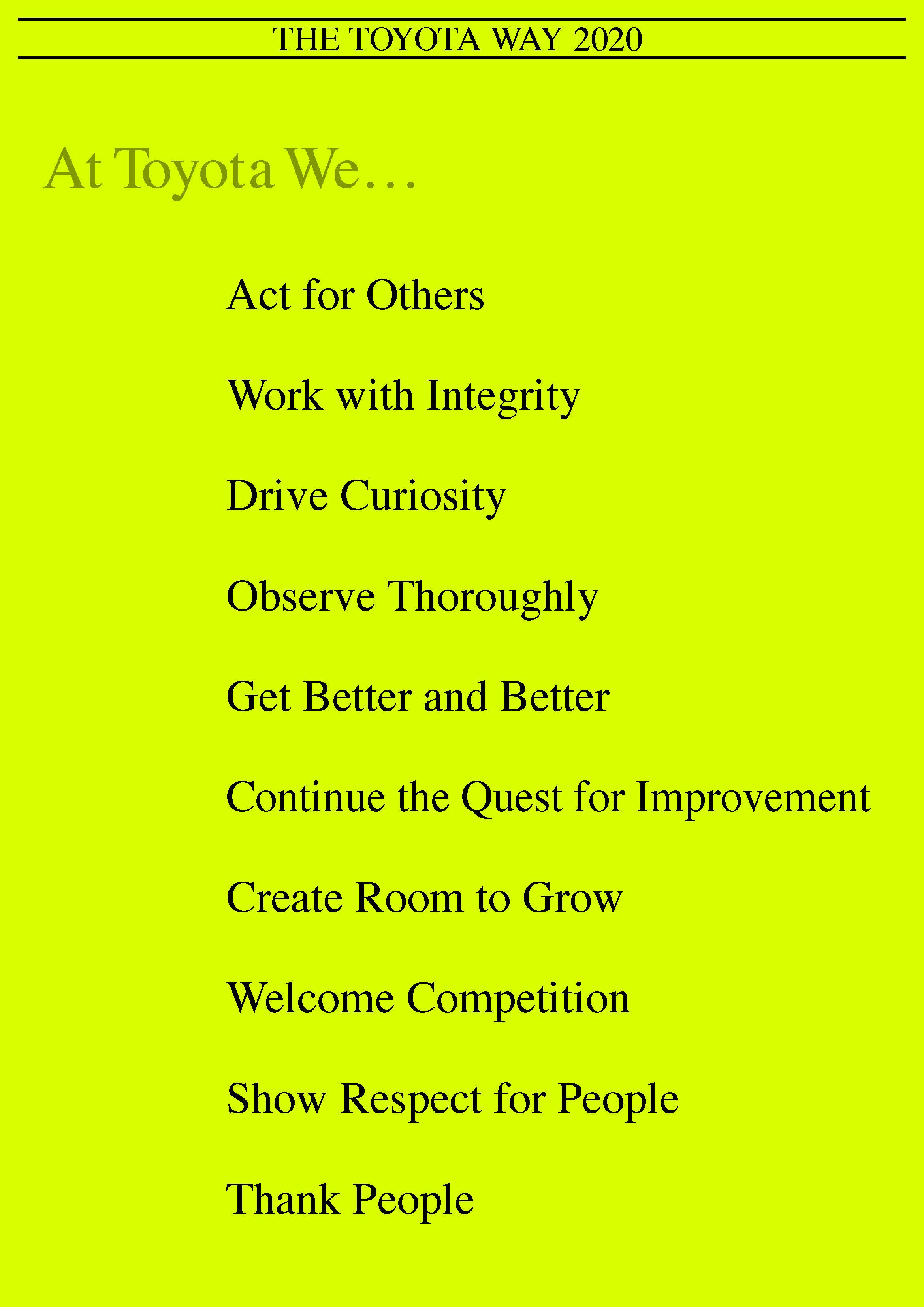

Furthermore, I learned about the corporate culture of looking after people through my encounters with the members of Toyota. The Toyota Way is a code of conduct that includes the maxims, “Act for others” and “Thank people.”

I learned that cars were given to Lebanon as part of activities to support refugees. At a dealer in Japan, I was shown an initiative they’re implementing to support the mobility of elderly local residents.

I was impressed by how Toyota really cares about people and society. The company isn’t just interested in making money. My respect for Toyota has deepened even more.

Ibrahim

I learned that you don’t just install sensors to automate everything at plants. I learned the importance of fully using your understanding when you make kaizen (continuous improvement) without spending too much money.

I was really surprised when I visited the Lexus plant in Kyushu. I had this image of it being lined with state-of-the-art equipment and sensors, but it was actually a very simple factory that made clever use of various karakuri mechanisms. I learned that people at Toyota really value making improvements at the level of 1-second and 1-yen increments in all processes. It’s the accumulation of these tiny improvements that result in profits.

My image of Toyota also changed. Until I started this internship, I imagined that Toyota was all machines, including cars and production lines. But meeting the people of Toyota made me see the warmer, more human side of the company.

On the first day of my internship, we were welcomed online by more than 80 people. I was really surprised to receive such a warm welcome. Watching the way supervisors communicate with subordinates also made me realize how everyone is just like one big family.

I was also very impressed with the long-term relationships between Toyota and its dealers and suppliers.

As the world’s leading automobile company, I thought Toyota would place the greatest priority on sales and profits. But they place even greater priority on building relationships based on trust with dealers and suppliers. Everyone in the value chain cooperates with one another to overcome difficulties. I think this is extremely unique.