In a new workshop centering on TPS to help create "TPS Leaders" across the company, Akio seeks to narrow the gap of understanding on its two pillars - Jidoka and Just-in-Time - by sharing his interpretation of them.

In May, at Toyota’s financial results briefing, Akio reflected on the efforts the company had made over the previous few years, saying:

“Over the past few years, we came to feverishly engage in both ‘a fight to bring back what makes us Toyota’ and ‘completely redesigning Toyota for the future’.”

What exactly did he mean when he said “a fight to bring back what makes us Toyota”? Revisiting messages he gave starting from a few years ago, one of the things he repeatedly has said that makes us Toyota is the Toyota Production System, or what is often called “TPS” in short.

Recently, internally at Toyota Motor Corporation in Japan, a new training program was started to nurture a select group of so-called “TPS leaders” across the company from various divisions. The first cohort of the new program started this summer, and the program itself is expected to continue for a certain period of time. As a symbol to emphasize the importance of the program and to share his own thoughts as a lecturer about TPS, Akio joined the kick-off session.

TPS may no longer be strictly an internal term at Toyota as there are now many books from external experts explaining TPS. These experts outside of Toyota often refer to TPS in management, manufacturing, or other process-development books and/or seminars about how Toyota’s manufacturing is conducted. However, Akio’s angle seemed to be a bit unique, and even used some rather usual explanations.

Toyota Times also joined the session and hopes to share how Akio explained the topic of TPS at the training session. However, please note that he said that it’s “his way of looking at TPS.”

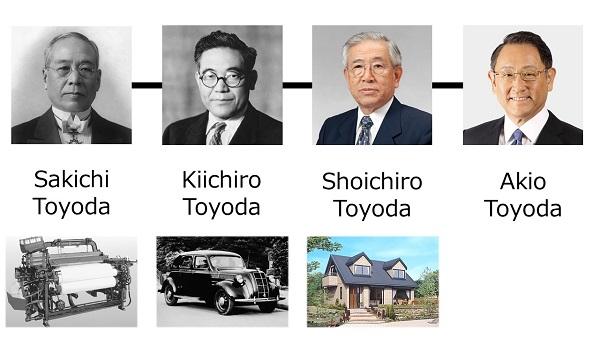

1. Sakichi Toyoda looked to ease his mother’s burdens

The purpose of the training program is for Toyota’s management leaders who don’t work at manufacturing frontlines to gain a deeper understanding about TPS to help the company accelerate its efforts to bring back the essence of “what makes it Toyota” as it looks to completely redesign Toyota for the future.

Akio started off the lecture by showing reports that had been submitted by the participants in advance, saying, “it’s really typical of HR and their style of work that requires you to make this kind of report.”

This drew some laughter from the participants. Akio continued, discussing the reports:

Akio

I felt that all of you sufficiently captured certain keywords used at Toyota, but something that concerned me was your stated determination to try to “change Toyota any way possible by utilizing what’s learned and obtained through this program.”

It is OK to have determination to make changes, but if you change everything without a solid concept or target, you may end up just making things worse.

There are two key concepts deeply rooted in Toyota since its foundation, or even before then. Do you know what they are?

Participant A

I think it is TPS and cost reduction.

Akio

TPS and cost reduction, I see. (Pointing a different person) How about you? What do you think?

Participant B

I think they are “Just-in-Time” and “automation with a human touch”, or “Jidoka”

Akio

That’s it! This is what I wanted to hear! (everyone laughs)

I suppose you all think you understand what they are about since you have been told that the two terms are the main pillars since you joined Toyota.

Some of you probably do understand, and some of you may feel you do while you may not.

That is why I volunteered to be the lecturer today to help kick-off this TPS training program. Hopefully, I can help narrow the gap of understanding Jidoka and Just-in-Time between us.

First of all, let’s talk about Jidoka, but it’d be easier to explain the concept by first showing the automatic loom invented by Sakichi Toyoda…

The participants then moved with Akio to the back of the classroom where an automatic loom was showcased.

Akio

Sakichi was the son of a carpenter. It was said that he read various books and studied every day, thinking about ways he could make a contribution to society. Then, one thing came to mind while the young Sakichi was thinking about his mother, and how she toiled to weave fabrics every evening and late into the night. He wondered if there might be a way to ease her burden. That was the focus of young Sakichi’s attention.

It may be well known that Toyota started from the invention of a wooden hand loom, but the background of why Sakichi dared to invent such a machine may not be known as much.

Back when Sakichi developed his first automated loom, people had to use both hands to control the threads of warp and weft. His invention allowed for his mother to operate a loom using only one hand. His invention also helped improve the quality, increasing overall efficiency and dramatically improving productivity.

Akio

Often at Toyota, TPS is considered the process of making things efficient, and you talk about changing the way of work as the purpose of applying it in that context. But I think the purpose should be to make someone’s work easier, and I believe this is the most reasonable way of understanding what it really is about.

Then, Akio directed the participants to the next machine, called the “Type G automatic loom.”

2. Improving productivity was not the main purpose

Akio

This “Type G automatic loom” is the machine that helped drive a drastic full model change of Toyota’s business.

Automatic looms used back then were always monitored by one operator with a mindset of “one person, one machine”. People were the guard of each machine.

Why do you think it was that way?

It was because operators were unable to predict when “abnormalities” would occur.

You might be wondering what the “abnormalities” were when weaving fabric with automated machines.

The most common one was when thread ran out or got cut off for some reason.

This machine was able to detect such abnormalities at a time when there were no “sensors”.

With this automatic loom, Toyota was able to secure the capital required for it to shift its business model from an automatic loom manufacturer to a car manufacturer. This was enabled because a world-leading automatic loom company in the United Kingdom asked Toyota to sell this automatic loom technology to them.

The primary feature of the technology was that it had created a system to detect abnormalities in the production process.

The Type G automatic loom has a spring for threads of warp and weft respectively, which uses its power to determine when the thread runs out and lead to replacing it with a new one automatically, without the use of modern sensors or motors.

Akio continued on in his explanation of what improvements were made when replacing thread, after determining when the thread runs out.

Akio

When the thread runs out, this machine automatically brings another new wooden pipe with new thread. The wooden pipe needs to have its thread end out on the surface, and before this machine was invented, workers had to suck it out by themselves. The problem was that there were lots of cotton dust and workers often had their lung damaged because of that process.

The invention developed by Sakichi and his colleagues included a new feature that made it not only easier, but safer for the workers by automatically bringing thread end out on the pipe to where needed when the thread had been cut off.

Akio

This is one of Sakichi’s inventions.

When we say “invention”, it may sound like something very advanced, but it was actually the result of Sakichi simply exploring a desire to do something for his team members at the manufacturing frontlines who were suffering damage in their lungs.

With this Type G automatic loom now equipped with a system to detect and manage abnormalities, productivity dramatically improved. But please note that the improvement in production was just a result [of trying to help his team members].

Thus, seeing the employees suffering from damaged lungs, and hoping to keep the machines from stopping due to abnormalities, a job that required the employees to always stay close to the equipment, Sakichi aimed to create a system that would determine what the abnormalities were caused by and then coming up with ideas to prevent or stop such abnormalities. As a result, productivity improved.

It’s not the other way around. It’s not that he did all this just to improve productivity.

Sakichi’s inventions were all rooted in going and seeing the manufacturing frontlines, and thinking about how to make people’s work easier. One result of doing this was improving the efficiency-Akio stressed this point.

3. How Akio sees Jidoka (automation with a human touch)

Akio

Again, this is just how I see it, but Jidoka is about being centered on people.

It’s about thinking as if you were the one working there.

You can’t just make orders to improve efficiency or reduce resources while you are in a safe zone and not at the frontline.

There’s also this idea about adjusting the work to match the full output of one manpower (pursuing Ichi-nin-ku in Japanese).

This concept of “Ichi-nin-ku” means the amount of work, the workload or capacity, that one worker can or should accomplish in a day. Akio continued his explanation on this.

Akio

Let’s see why we pursue this idea.

We all only have 24 hours in a day. You don’t get more hours, like 48 hours in a day, when you are busy.

This 24 hours is a condition equally applied to all. That time includes family and a private time, but a lot of it is devoted to work for a company.

Knowing this, supervisors must make the work being done by team members as meaningful as possible. That is what Toyota’s manufacturing frontlines have been pursuing.

In other words, increasing work that truly adds value while reducing work processes that are redundant or cause team members to wait.

So my personal take on TPS is that it is “centered on people,” and this is the mindset I would like for all of you to take with you.

Sometimes TPS is seen as something that is there to enhance work.

One of the ideas embraced within TPS is an obsession to eliminate things deemed unnecessary or that interrupt work, such as waste, overburden, and unevenness. However, that might lead people to imagine harsh working conditions where no rest is allowed.

But knowing that TPS originates in the idea of making work for someone like your own mother easier, people might come to form a different impression of what it is really about. Similar to what Sakichi pursued, it is about creating more free time for workers by eliminating waste in work processes to reduce overtime. When the value of a worker’s time is realized, work is adjusted to maximize the output possible from manpower.

4. How Akio sees Just-in-Time

Next, Akio shifted to explain the other pillar of TPS, Just-in-Time.

To illustrate this concept, it is time to turn to Sakichi’s son, the founder of Toyota Motor Corporation, Kiichiro Toyoda, who introduced and implemented it. A phrase that is commonly associated with this concept is: “Provide what is needed, when needed, in the amount needed”. On this concept, Akio offered a unique explanation. When reading the back and forth between Akio and a workshop participant, please pay attention to the key phrase of “lead time.” Here, it is specifically referring to the amount of time required for products or services to be delivered from when they are ordered.

The conversation will include the discussion leading up to it as it was also interesting.

Akio

What comes to your mind when you think about Just-in-Time?

Participant C

Provide what is needed, when needed, in the amount needed.

Akio

That’s correct, but what is the practical meaning of it?

Participant C

Um…

Akio

Considering a “what is needed when needed” approach, to respond quickly to customer needs, there would need to be a lot of inventory, right?

Participant C

Normally, yes.

Akio

One finished vehicle consists of about 30,000 parts.

Participant C

Right…

Akio

So, it would follow that for a production line to flexibly produce orders quickly, a tremendous amount of inventory would need to be present, right?

Participant C

But if we know and can meet what customers want…

Akio

Who do you mean by “customers”?

Participant C

Each downstream process… or our final end users.

Akio

But we sell around 10 million new vehicles annually, and that means we have the same number of customers. How can we understand what is needed by each specific customer? It would be impossible to do.

So what do we do? We have to have a lean operation in place to detect abnormalities right away and stop what is in the pipeline so that we can make improvements quickly.

And that’s why we need just in time.

Granted that this is my way of understanding it, but I think the “tool” or “concept” that helps make this easier to understand is “lead time”

At Toyota, a common term for the next process, whether it be in manufacturing or in an office workflow, is “downstream process” or “Ato-Kotei” in Japanese. Those in the downstream are considered a “customer.” When thought of this way, those engaged in the work will try their best to avoid providing their downstream customers with defects. If this mindset is adopted and ensured in each process, the result is that there will be no chance that the final end users receive something defective.

In addition, the workers also start thinking about how they can contribute to making the work at the next process easier, making adjacent processes collaborate to make improvements. The result from those efforts is higher productivity, and how it should be achieved, according to TPS.

Usually, people working at Toyota think that “Just-in-Time” is only about delivering their product to a downstream process in a just-in-time manner, but what Akio was trying to convince the participants to do was to look at the bigger picture, to consider and think about it from his perspective, where he sees things as they relate to the company as a whole and how to deliver Toyota’s vehicles to the end customers “just-in-time.”

Often, even with the same model being produced, there are many variants.

The variants can include trim, exterior color, interior color, audio…etc. Using only Prius in Japan as an example, the number of possible patterns would be more than 14,000. Surprisingly, this is even the result of efforts to reduce the number of patterns; it was more than 48,000 before. And this is only for the Prius in one market! The number of patterns would be much larger when including vehicles bound for overseas markets.

If all kinds of inventory has been built, it may be possible to provide vehicles to the customer in what feels like a more true just-in-time fashion (time from order to delivery), but on a scale this large, it is not possible. However, this does not mean that Akio is saying to give up. Rather, he insists that the goal should be pursuing shorter lead time and continuing to do things in a just-in-time way as much as possible.

5. Achieving lead time at Sushi restaurants?

It was here in the lecture that Akio shared an example related to food to get his point across, in the form of how operations are done in authentic Sushi restaurants in Japan. Sushi restaurants are known for the freshness of their products, but also for their ability to take orders and fulfill them quickly.

Akio

When you go to supermarkets, there are lots of final products immediately available for you. But when you go to an authentic Sushi restaurant, are the finished orders just waiting in front of the chef?

I don’t think so.

Sure there are large pieces of raw fish prepared, but are they cut into pieces in a final form? No.

After you place your order, the chef takes out a slice of the raw fish, cuts it to size, combines with rice to make the sushi piece and delivers it to you. The point I’m trying to make is that keeping lead time short is something that matters.

You can’t prepare every specification in advance for 10 million customers.

It’s important to understand what we can’t do. The key then is trying to shorten lead time.

Therefore, similar to the Sushi example, the ideal for Toyota would be to manufacture vehicles just after an order comes in from customers, by having preparing parts on hand to quickly assemble and then deliver to customers, but that is not realistically possible.

That is why Toyota believes and places emphasis on continued efforts to shorten the lead time at each process.

6. “Genba” matters more than titles

After Akio completed his explanation, one participant raised his hand and shared a comment.

Participant

Thank you very much for your time today. I’ve been at Toyota for 20 years now, and this was my first opportunity to be this close to you, so I’m pretty excited.

When I had just joined the company, my general manager taught me that “work is about to making life easier for others.” Now, 20 years later, hearing your view on Jidoka, or looking to take unnecessary burdens from others around you, I feel like everything has come together in this moment.

The energy and passion I felt from you today is something I will take back and share within my division and beyond.

In response, Akio took a moment to share his experience when working on productivity improvement at dealers, something he did when he was a project general manager years before.

Akio

I would often face challenges when doing kaizen activities together with dealer staff members.

Whenever there were issues, the mechanic or the sales staff at the frontline were bothered most by it.

Though they would share issues with upper management through daily reports, often it was not really understood.

I asked them “Why didn’t you report the problem to the sales manager earlier?” To which, the sales manager replied: “You are definitely from Toyota -- that’s exactly what I said at the regularly held sales manager’s meeting!”

I replied “But the sales manager’s meeting is held once a week only, right?”

Then, I met with a sales executive at the dealer, and asked the same thing – to which he replied “That’s exactly what I always request at the regular executive meeting!”

But as you can imagine, that executive meeting is held only once a month.

So this is partly why I decided to abolish certain titles.

When it comes to implementing just-in-time processes, the person in charge or subject matter expert is the most important. A daily report may be more beneficial than other reports or meetings.

As a title gets higher, the frequent may be reduced to be weekly, monthly, and annually.

They say people with titles make decisions, but the speed of kaizen gets slowed down there.

We spend 365 days minus weekends and holidays at and for the company. Therefore, I think it’s important to use the time to change what’s happening in front of your eyes every day, rather than getting stuck in hierarchical bureaucracy.

So please don’t take 20 years to figure it out (wink). Make it a daily basis. Think about how much more impact it will have.

If you spend those days focusing on titles, etc., instead of thinking of how to change things daily, just think about how much time you wasted.

That’s why my request is that you be nimble enough to make improvements and shorten lead time on a daily basis.

In this way, Akio explained that abolishing certain titles in the hierarchy of Toyota, including executive vice presidents, aims to speed up the kaizen process. Shortening lead time for customers, making existing work processes easier for colleagues, and improving the quality of the time spent for work for the sake of each member and the member’s family – that is what TPS is about. Titles do not help achieve that. As such, things noticed or learned every day at the frontlines becomes a source of kaizen. This was the message that Akio wanted the participants to take with them.

7. Editorial Postscript | Doing things for others

Toyota Times previously introduced stories about how Toyota’s team members were dispatched to Funahashi, a rainwear company, to offer their know-how of TPS to help them produce even more medical protective gowns.

When the Toyota Times editorial team visited the company, the biggest challenge was to tell which members were from Toyota and which were Funahashi’s regular working members.

The reason for this was because the Toyota team members had taken off their Toyota working jackets, and, in the same way, removed their own titles, so they could work energetically with the teams at Funahashi. In fact, later it was disclosed that they had done this on purpose. These TPS experts knew that by doing so, they could work closer to those at the genba, who’s feedback mattered most, to use as the source for finding kaizen.

As they worked together, if a colleague complained they had a backache, the TPS team took that as a clue, spending time to discuss possible solutions, resulting in changing the height of the work table. On another occasion, when a colleague in front of one of the TPS team members was searching for scissors, the expert identified this as something wasteful, leading to a dedicated space for scissors.

Similarly, back when Toyota was just getting started, Sakichi was there at the frontlines, observing his mother and trying to figure out how to make her work easier, something that eventually led to the invention of the Type G automatic loom.

The simple truth is that TPS was founded on the idea of “doing things for others”, an idea that was inherited from the Sakichi era and continues to be practiced, with some pretty outstanding results, today. When Akio talks about bringing back ‘what makes us Toyota’, he is really talking about this value of doing things for others, the true heart of TPS.