A special project team worked on reviving a Toyopet Racer, Toyota's first racing car from over 70 years ago. In the seventh installment of this series, the seat is built from scratch.

This series features Toyota’s project to revive a legendary racing car—now on display at the Fuji Motorsports Museum—with a look at the project members’ efforts as well as the history and meaning behind the vehicle.

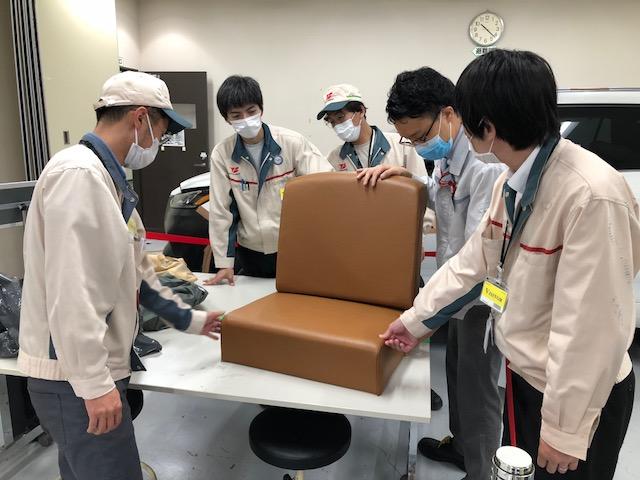

This article follows the efforts of members who developed and created the racer’s seat from the ground up.

It has to look good too

Toyota produced its first racing car, the Toyopet Racer, some 70 years ago. When the project team recreated the vehicle, they could draw on original blueprints and the base models for certain components like the engine. For others, however, the only clues were photographs of the racer. The seat was one such part, for which old black-and-white images were all that remained.

For the cigar-shaped, open-topped Toyopet Racer, the seat is also one of the key aesthetic elements. But this revival project is not just about looks—the seat serves a vital function in ensuring that the car drives just as it did back in the day.

The seat’s importance is explained by Masashi Watanabe of the Body Technology Development Div., who worked on the machine’s packaging, determining the layout of components such as the engine, seat, and transmission.

Watanabe

For the seat, unlike other parts, we don’t have a great deal of development and manufacturing expertise within Toyota. Our seats are made by a group company, Toyota Boshoku. I myself have zero knowledge of seats. That’s why I realized from the outset that turning to Toyota Boshoku was our only option.

The seat must look the part to recapture the car’s original feel, and it also affects driver safety and comfort. We wanted to get it right, and we needed to get it right. But since I don’t know what that entails, I asked Toyota Boshoku to be involved right from the planning stage.

Nurturing the next generation

In April 2021, Watanabe’s request led to the creation of a seat restoration project team, consisting mostly of junior employees, at Toyota Boshoku’s Sanage Plant in Toyota City.

Yoshimi Minoura of Seat Design Div. No.1 led the Toyota Boshoku contingent.

Minoura

My supervisor suggested that the development and production should be led by our younger guys to help nurture their talent. We put together a team of eight, including myself, all in their 20s and 30s, and the development got underway.

The other members were Shun Sudo (Seat Cover Engineering Development Div.), Hikaru Taniyama (Prototype Div.), Yusuke Uekawa (Seat Evaluation Div.), Satoshi Yamaguchi and Minato Kataoka (Design Div.), Nagomi Sugino (Seat Planning Div.), and Hiroaki Yasuda (Material Technology Development Div.).

Minoura

Although our company had restored old car seats before, I had never been involved in that work, so I was very unsure at first. All we had to work from were photos of the original racer. To make a seat, you have to determine its structure, size, and requirements for how strong it needs to be. However, within the company, we had no clues as to what materials were used or how it was made. We decided to visit the Toyota Automobile Museum to study other seats from that era.

Alongside his initial seat discussions with the Toyota Boshoku team, Watanabe was also working on the car’s packaging with other members of the racer project, trying to find an ideal configuration for positioning the engine, transmission, driver’s seat, and other components within the machine. This work began with drawings and moved on to 3D CAD.

As Watanabe tells it, the trickiest part of packaging was the driving position. In the old photos, there were no seatbelts. According to the son of a Toyopet Racer driver, you had to cling onto the large steering wheel that was sandwiched between your legs.

Watanabe

By the end of a race, they had no strength left to grip the wheel and placed their arms over it instead. Personally, I wanted to recreate that original driving style. Then we would be able to see what those pioneering drivers saw, which is something I really hoped to do.

However, other members felt that seatbelts were necessary for safety reasons, sparking a heated debate. Like production vehicles, if the Toyopet Racer was to be driven by people, safety had to be the highest priority. Watanabe compromised by making the seatbelts detachable. The belt anchors were also positioned to be less visible from the outside, so that they weren’t noticeable when the car was on display.

A mockup was then built to test the driving posture. The team also used virtual reality to finalize the overall packaging, including the seat.

Studying the Automobile Museum’s seat collection

Toyota Boshoku began developing and manufacturing automotive seats in 1970, starting with seat fabric production. That means even the company that now designs and makes all of Toyota’s seats had no information or expertise about seats from the 1950s.

The Toyota Boshoku team therefore checked the materials, construction, and installation methods of various seats among the Toyota Automobile Museum’s monoposto (single-seater) racing car collection, including the Bugatti Type 35B (1926), a pre-World War II Toyota AA passenger car (1936), and the first-generation Crown RS (1955). Their observations provided a reference for figuring out how to make the seat and which materials to use.

Minoura

While the metal seat frames and leather or synthetic leather covers have not changed much, back then they also used wood in the frames, and the padding that is now mostly polyurethane consisted of coconut fiber. Another thing that surprised me was how the seats were secured. In more recent cars, the basic approach is to bolt them onto the body to guarantee strength and safety, but in those days, they were simply slid in. That was a shock.

With their coil springs and coconut fiber, car seats of that era were built similarly to household sofas. To save effort and expense, the team probably could have repurposed something that was already available on the market. However, to ensure that the materials and specs were as close as possible to the original, Watanabe and his colleagues decided to start from scratch.

Watanabe

We set out to build the seat we truly wanted, without compromising on looks or comfort, channeling the spirit of the people who created it originally. Because the materials and construction are completely different from modern seats, we had a very hard time.

Sugino

We chose the reddish-brown color after looking at catalogs, magazine articles, and ads from that era. As for the material, we went with PVC (polyvinyl chloride) since it was available at the time and would be exposed to the elements. We reproduced the glossy finish found on seats of a similar vintage that we viewed at the Toyota Automobile Museum.

At Toyota Boshoku’s facilities, Watanabe and his team thoroughly tested seats with various specifications, adjusting coil spring strength and the thickness of the felt, coconut fibers, polyurethane, and PVC surface. Besides putting their creations through testing equipment that is currently used in seat development, they also sat in each one to gauge the comfort.

The configuration they came up with consisted of coconut fibers and polyurethane pads layered atop coil springs and covered with PVC upholstery. Many of the coil spring seats in the Toyopet Racer’s day were soft and bouncy, making it difficult to settle into them. By adopting this particular construction, the team created a seat that could hold the driver firmly in place even under significant stresses from the road surface, providing stability for driving.

Minoura

Much of the debate was about the structure of the coil springs. We asked various people from the Evaluation, Design, and Seat Cover Engineering Development divisions to try sitting and give us feedback. It was a process of repeat trial and error, making improvements in response to their suggestions about stability and other issues. Aside from the springs and upholstery material, pretty much everything was developed and produced in-house, allowing us to get the details right. I’m very pleased with the result.

Watanabe

My main concern was the appearance, but when I sat in the final version prototype I was blown away by the level of comfort. The seat is really well done, to the point that I felt that this kind of seat could be good for some of the cars on the market today.