Toyota won't allow its BEVs to become commodities. Amid calls for a shift to electric vehicles, the company's latest technologies brim with the passion of engineers who love cars.

In June, Toyota’s Technical Workshop offered participants the chance to try out various technologies spurred by the new leadership’s focus on electrification, intelligence, and diversification.

Though Toyota Times has reported on the next-generation batteries and fuel cell (FC) systems, the event also featured many other cutting-edge technologies that we have yet to share.

This series of articles will delve into several such technologies, grouped by the three main themes. First up, Toyota’s commitment to “BEVs created by carmakers.”

A “beloved” industrial product

The workshop was the brainchild of Executive Vice President Hiroki Nakajima, who serves as Toyota’s Chief Technology Officer. At the new management team’s policy briefing in April, he pledged that, in 2026, the company will “release next-generation BEVs entirely different from those of today―BEVs created by carmakers.”

BEVs created by carmakers. How will they differ from those built by the industry’s battery-makers and tech startups?

When workshop attendees raised the question, Vice President Nakajima prefaced his response by saying, “I think the value offered by cars changes with the times…”

He went on to say, “Yet even as the ways people use cars change, going for a drive still excites, thrills, and brings smiles to our faces. As the Chairman (Akio Toyoda) notes, cars are the only industrial products spoken of as ‘beloved,’ and I believe that BEVs created by carmakers must inspire such emotional attachments.”

On display at the workshop venue were technologies into which Toyota’s engineers had poured their passion, seeking to ensure that cars remain manufactured goods worthy of affection.

BEVs can still be fun to drive

One of the technologies unveiled at the event was a manual BEV.

Despite being an EV with neither engine nor gearbox, the car reproduces the feel of a manual transmission through motor control, as drivers operate the shift levers and clutch pedal.

The drive is filled with a carmaker's attention to detail, from powerful acceleration in the lower gears to the shift shock that accompanies a mistimed change.

With automatic transmission available at the press of a button, family members who only drive auto can also confidently jump behind the wheel.

At the event, Toyota also demonstrated a BEV that drives like a compact Passo or a Lexus LFA supercar and everything in between.

Various aspects, from driving feel and comfort to engine noise, can be adjusted on demand by simply updating the car’s software. Perhaps someday soon, we’ll be able to pick our driving experience to match the day’s mood, whether it’s an old favorite, a dream ride, or a performance-spec sports car.

The workshop lineup also included a Lexus RZ featuring “steer-by-wire,” as previously showcased on Toyota Times.

By controlling the steering wheel and tire angle with electrical signals, this technology offers a new driving experience with handling that is more intuitive and greatly streamlined. With no need for mechanical connections, the steering wheel can also be positioned more freely, opening up possibilities for new mobility innovations.

Its distinctive shape, reminiscent of aircraft controls, also serves to build excitement for the driving experience to come (see top image).

Boosting performance by downsizing drive systems

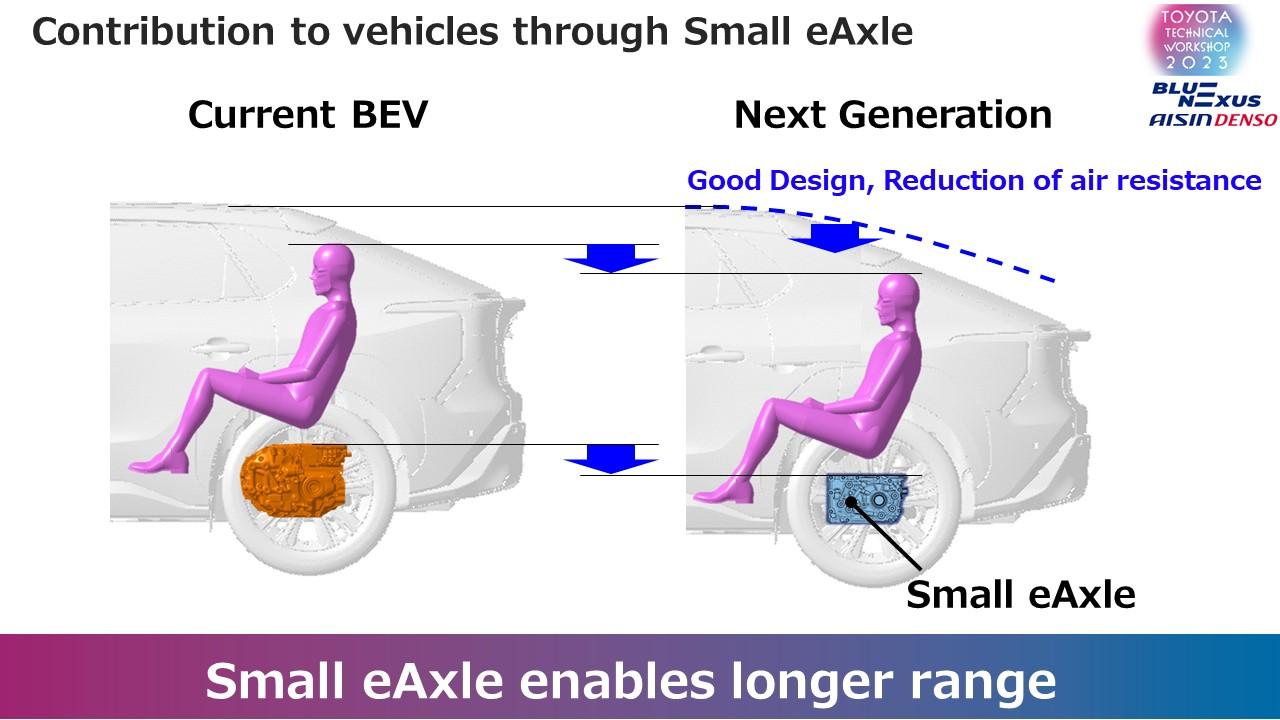

In BEVs and other motor-powered cars, the eAxle combines the main components needed to make the vehicle run (motor, gear train, and inverter). At the workshop, Toyota unveiled a compact model currently in development.

The project brings together the technologies of BluE Nexus, a venture set up with funding from Aisin, Denso, and Toyota.

Along with increasing the motor’s RPM and optimizing the shape and placement of magnet slots, the compact eAxles leverage technologies have been cultivated for hybrid vehicles (HEVs), including lubrication design and fluid analysis technologies, reduced PCU condenser capacity, and improved cooling performance. The motor is roughly 40% smaller than that of a hybrid, while the gear train and inverter are slimmed down by 53% and 58% respectively.

These improvements lower the cargo area floor by 70 mm, freeing up 50 liters of additional interior space. The roofline can also be dropped, reducing drag and allowing designers to pursue more stylish silhouettes.