The theme of the first part was communication and how to deal with failure, but then the discussion gradually shifted to quality itself.

At Akio Toyoda’s Juku (roundtable with employees) on Quality, held November 16 as part of the 56th All-Toyota TQM Competition, following the first part, the second half of the discussion went deeper.

Question 3: Taboo phrases to use at Toyota

Many of the most popular questions focused on communication. Some, like the following, even drew laughter from the venue audience.

- Can you tell us three phrases you consider taboo in our effort to make ever-better cars? I‘ll ban them starting tomorrow!

Akio

The three phrases I regard as being taboo would have to be: (1) I’ll think on it and try to do better, (2) We’re doing that, too, and (3) We need more man-hours and money first. These are the three phrases we mustn’t use at Toyota.

Whenever I point out things to improve, people often reply by promising to think about it and try to do better. But in 12 years of being president, I’ve found that some people stop at thinking on their mistakes, and never change.

People are also often quick to say, “We’re doing that too,” but they don’t realize what they’re actually doing is slightly different.

There are also those who always say, “We don’t have enough people or money” whenever you try to do something new. These would be the three major taboo phrases I would choose.

People like that don’t have the will to find the necessary time or money. If you want something at home, you wouldn’t say to your husband or father, “Can you double your income?” You would scrimp and save so you can buy it, right? It makes you wonder why they can’t do that at the workplace too.

Kawai

People at factories also say they want us to hold all kinds of seminars to teach them new skills. But when they take part in inter-departmental contests like the Skills Competition, they find the necessary time and money and practice on their own,, because they want to win. They don’t complain then.

They say they want more time and money, because they feel like they’re being forced to work on something new. You can make time by changing people’s attitudes.

It’s fine to reflect on your mistakes, but you have to realize that something is wrong when you make the same mistake twice.

Question 4: Akio’s efforts to improve communication style

The discussion moves on to Akio’s efforts to change the communication style at Toyota.

In July this year, Akio spearheaded an initiative to deploy a digital communication tool for connecting directly with members who are part of projects that he is directly involved in.

It allows staff to connect to not only their own management level, but also many general staff working on-site. This ensures thorough information sharing, and leaves behind records of this communication and so promotes workstyle reforms through faster projects and human resource development.

Akio began talking about digital communication while referring to a weekly morning meeting attended by executives, including regional CEOs around the world.

Akio

Conventionally, the number of attendees at the regular morning meeting was limited by the meeting room size, and information about the previous week was shared only among vice-presidents and other executives.

Some things are difficult to convey through documents and words alone. They say a picture is worth a thousand words. So, we started making videos at some point. We began sharing information on not only what I did in the previous week, but also my thoughts on each event.

When it became difficult to gather people due to the spread of COVID-19, we started online meetings and inviting participants from oversea entities.

This allowed us to remove the physical limit imposed on us by the size of the room and gather huge numbers of people. Now we digitally connect over 200 people at once.

The key to physical meetings was to try and communicate with as many people as possible on a one-on-one basis. Our biggest tool at the time was nemawashi, or negotiating behind the scenes. But digital communication allows simultaneous and uniform information sharing with many people from a single source.

During the days of analog communication, talking to a supervisor may have been the final stage of a project. But today, I think you need to communicate with the supervisor, who gives out instructions, at the start to verify the objectives and intentions.

hen requests are made from the top down, supervisors sometimes fail to convey the intentions of the president to their subordinates. Subordinates do their best, but their work ends up being something that the president did not request, which is a waste of time for both parties. I believe digital communication will solve this problem.

I think there’s a generation gap, but today, we have many useful tools. Fusing the experience of older people with new points of views will lead to better solutions. I want everyone to take on the challenges of mutual cooperation in this area.

Question 5: TPS and TQM

To this point, the three men had answered questions taken in advance or asked by participants at the venue. But at this point, they invited online participants to ask questions, too.

This led to a question on Toyota Production System (TPS). Akio answered from the perspective of the philosophy that Toyota must pursue, and Toyota’s order of priority.

- I think talking about the results embodied in products and on-site manufacturing is also important for TPS. Can you give us some advice on the strengths of TPS based on the relationship between TQM and TPS?

Akio

It’s like there are two factions within Toyota, with those who believe in TPS and others who believe in TQM. But what Toyota needs are the philosophy, skills and conduct that make Toyota, Toyota.

When you ask production people, they say it’s about TPS, but quality people may say it’s TQM, so it’s like there are two factions. But within Toyota as a whole, TPS is our philosophy (or origin), while TQM is a way of thinking based on that origin.

At the same time, there is an order of priority to what Toyota must value. That is, we must prioritize safety, quality, quantity and profits in that order, as we promised during our public hearing.

But I think it was the other way around before the public hearing periods. We used to prioritize profits above all else, followed by quantity. Boosting quantity would also boost profits. I think Toyota used to prioritize making cars that would sell well, leading to greater profits.

Meanwhile, cars that didn’t sell well and were not very profitable, but were sought after by the market, such as the Coaster commercial vehicle , or the Land Cruiser, which is a strong part of people’s daily lives, became subject to longer model change cycles.

Only cars that sell well underwent model changes every four years. I think everyone used to take this for granted and no one ever questioned it.

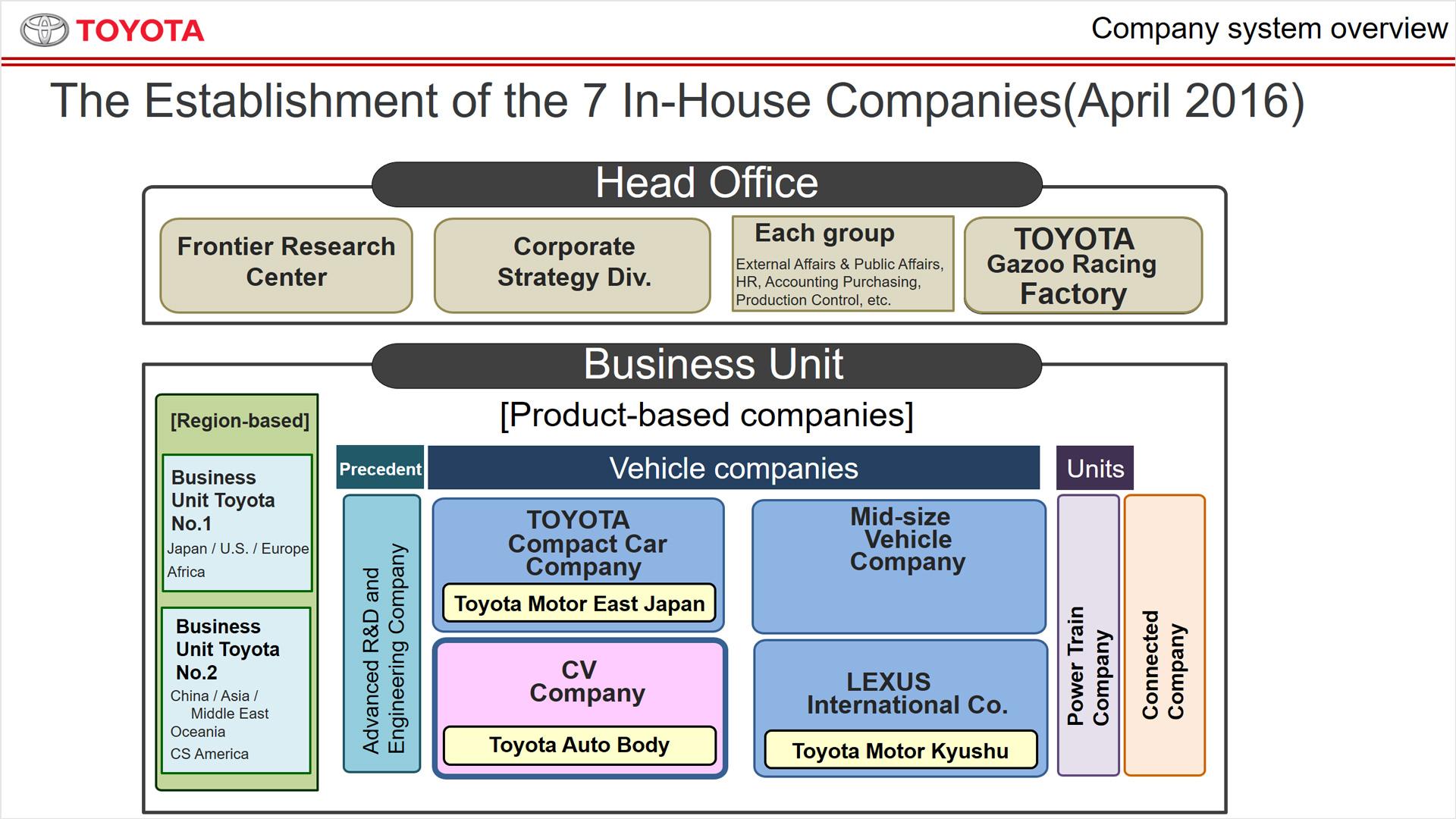

Then came, the global financial of 2008-2009. Afterwards, in 2016, Toyota adopted an in-house company system. Toyota Motor East Japan (TMEJ) was placed under the jurisdiction of Toyota Compact Car Company, while others were divided into the Lexus International, CV Company centered on Toyota Auto Body and Emerging-market Compact Car Company centered on Daihatsu.

We did this because we wanted to establish a system that would allow Toyota and its affiliated companies to focus with passion on their own models, instead of prioritizing models based on how well they sold or how profitable they were.

This resulted in Century, Coaster and Land Cruiser undergoing model changes.

This is our order of priority in developing products, and TPS becomes an important philosophy within that context. I believe it’s important to not only reduce costs as much as possible, but also to adhere to a philosophy, which in turn allows you to build skills accordingly.

Kawai described an example of this on-site.

Kawai

People working on-site too, say quality is top priority during meetings on quality, while they say cost is top priority during meetings on cost, or safety during safety meetings.

The concepts of ensuring quality during the production process, preventing defects, and boosting efficiency are precisely what TPS is all about.

There are standard operating procedures, but I’m always saying, “Standard operating procedures can be changed every day” and “What is best today is not best tomorrow.”

But you must always remember that “you cannot boost efficiency at the expense of safety.” I always reiterate this.

People in various departments may say different things about cost and quality during meetings, but they all share the same workplace. They all hold their own meetings, but many of them are unnecessary.

It’s time for everyone to cooperate in changing the way things are done.

Akio’s face darkened when the discussion changed from the topic of communication to the basic philosophy behind quality. In mentioning the improper motor vehicle inspection problem, he spoke of how ashamed he was of this problem that threatened the integrity of the entire company.

Akio

Quality was what gave Toyota an edge over other companies, and it almost destroyed the company too (in our recall crisis). But then the improper motor vehicle inspection problem occurred.

There weren’t enough engineers, but dealers didn’t hire more people. I think the system of hierarchy at dealerships places salespeople above service staff. It’s really shameful that this problem occurred in the service division which is directly responsible for ensuring quality. That was one of the reasons I decided to take part this time.

It’s OK for now, because I’m here at the top and I emphasize that our order of priority is safety, quality, quantity and profits. But I will eventually be replaced, and a time will come when a leader decides to place greatest priority on quantity and profits. We, here at the top now, will be long gone by then.

5,000 people, including people in younger generations, are listening to this. When something like this happens, I want you to recall what I just said, and ask yourself, “Are these really what Toyota prioritizes?”

You don’t have to try and remember. I too, found myself naturally repeating what I learned from my supervisors over many decades during the public hearing.

You may not fully understand the significance of what I’m saying right now, but I’m telling you these things in the hope that you too will find yourself reiterating what I say if you find yourself in a tight spot at some time in the future.

It was an event on quality, but the topic of conversation revolved mainly around communication and other issues that concern everyone.

A lot of what Akio talked about centered on the lessons learned from the recall crisis back in 2010. This testifies to the fact that the lessons learned from it can be applied not only to divisions involved in providing products and services, but a variety of other operations at Toyota.

During the public hearing, Toyota promised the public “not to run away, not to lie, and not to distort the truth.” Faced with that existential crisis, Akio made these vows himself, and in the 12 years since, he has asserted the importance of maintaining that order of priority. To this day, he continues promoting the importance of quality and safety above all else.

Amid the variety of problems that arise, Akio volunteered to take part in this TQM Competition. It is hoped that he was able to etch into the minds of all participants the importance of Toyota’s promises to society.