This series introduces various aspects of what a challenge of a hydrogen-powered engine is all about before the 24-hour race from May 21 to 23. The first features the hydrogen-engine vehicle's difference from a normal race car, and the three technologies that made the challenge possible.

On April 22, Toyota announced that it is developing a hydrogen-powered engine, an internal combustion technology that virtually emits almost no CO2. At the same time, the company also announced that a Corolla Sport equipped with this engine would take part in a race being held one month later (May 21-23).

The event in question is a 24-hour endurance race. Why would Toyota throw its new engine straight into the deep end with a race so grueling that even seasoned gasoline-powered cars often fail to finish?

At the press briefing on April 22, President Akio Toyoda explained the decision as follows:

Akio

I want to take up the challenge of working with hydrogen-powered engines, which represent a hidden potential for motorsports going forward.

The reason for competing in a 24-hour endurance race is that simply lasting three or five hours is not enough. You have to have done the preparation to last for 24 hours.

On top of that, I’m one of the drivers. Many people in Japan associate hydrogen with explosions. So, I want to show that it is safe by driving in a race myself.

The first time that a race car is fully set up and taken through its paces is known as a ‘shakedown’. For the hydrogen-powered Corolla, this shakedown took place on April 24, less than a month out from the race. This shows just how tight the development schedule has been.

Since then, the car has been tested on the track several times in preparation for the main race.

If this hydrogen-powered engine can be proven in practice, the idea of eliminating CO2 emissions by simply ‘improving’ current gasoline-powered cars already on the road will become a viable option.

Viewed in this way, the 24-hour race may turn out to be a major step towards achieving carbon neutrality.

To help as many viewers as possible enjoy this historic 24 hours, Toyota Times has decided to share our reports from the test track as ‘background knowledge’ for watching the race.

The first of this four-part series will delve into what makes this car different.

Same engine as the GR Yaris?

The base vehicle for this race is a Corolla Sport, one step up in size from the GR Yaris that Morizo (aka Akio Toyoda) has been driving for ROOKIE Racing.

However, according to Toyota’s lead engineers on the project, Naoaki Ito and Naoyuki Sakamoto (chief engineer) of GR Project Operation Div., the race car is being fitted with the GR Yaris’s 4WD system. What’s more, they say that the engine has been converted from the GR Yaris.

Wait a moment – isn’t the engine hydrogen-powered? How could that have been ‘converted from the GR Yaris’? The engineers explained in more detail:

Naoaki Ito

For this hydrogen-powered engine, the engine itself remains the same as before. Our concept for this project was to create a hydrogen engine by using as much of the existing internal combustion technology as possible. We thought that achieving this would enable the conversion of existing car engines to hydrogen, providing a powerful weapon in the quest for carbon neutrality.

Although we said that we have ‘converted’ an engine from the GR Yaris, it would be more correct to say that ‘we have been working to enable conversion’.

Hydrogen has a higher ignition temperature than gasoline. What efforts were made to ensure that the same engine could support stable hydrogen combustion?

Naoaki Ito

We believe that attaining carbon neutrality will require not only building new cars, but also utilizing and improving the cars and technologies that already exist. To that end, we sought to make conversion possible with minimal component changes and control technologies.

We’ve been working at this for several years now, and it certainly hasn’t been easy. Initially we tried a bi-fuel approach, using 50 percent gasoline and 50 percent hydrogen. In 2016, Morizo himself tested the car.

From there we attempted 100 percent hydrogen, but initially the engine broke down within five minutes. Thinking back to those days, taking on a 24-hour race seemed beyond even our wildest dreams.

How, then, did the development come so far as to make the 24-hour race a possibility? The engineers answered this question by sharing the three key factors.

Three stories that explain how the hydrogen-powered engine roared to life

First was the technological innovation in injectors.

An injector is a device that sprays fuel into the engine. In gasoline engines, they inject liquid gasoline into the engine as minute particles.

For the new hydrogen-powered engine, however, the fuel is a gas. It took much effort to come up with technology that could inject this hydrogen in a way that ensures efficient and stable combustion.

The task of producing this technology has been promoted by a Toyota Group supplier, Denso, which has a long history of developing injectors. Denso’s engineers have been working on such technology since before the term ‘carbon neutrality’ became commonplace.

Ito expressed his gratitude for Denso’s efforts to date, saying ‘this is thanks to everyone at Denso, who kept striving with us, undaunted by all the failed attempts’.

The combination of Denso’s injectors and Toyota’s direct-injection engine technology overcame the obstacle of stable temperature control during combustion, bringing the dream of a 24-hour race appearance one step closer to reality.

Made possible by Mirai

The second story concerned technology for carrying hydrogen. Here too, Ito credited the existing hydrogen tank technology from the Mirai.

A tank that can safely store hydrogen on-board at high pressure and deliver it as fuel – Toyota had been developing this technology alongside the evolution of the Mirai, from first to the second generation.

The way that hydrogen is used in the Mirai, which is powered by electricity generated through the reaction between hydrogen and oxygen, differs from the hydrogen engine, which involves the combustion of hydrogen. Despite this difference, the technology for carrying hydrogen could be borrowed directly from the Mirai.

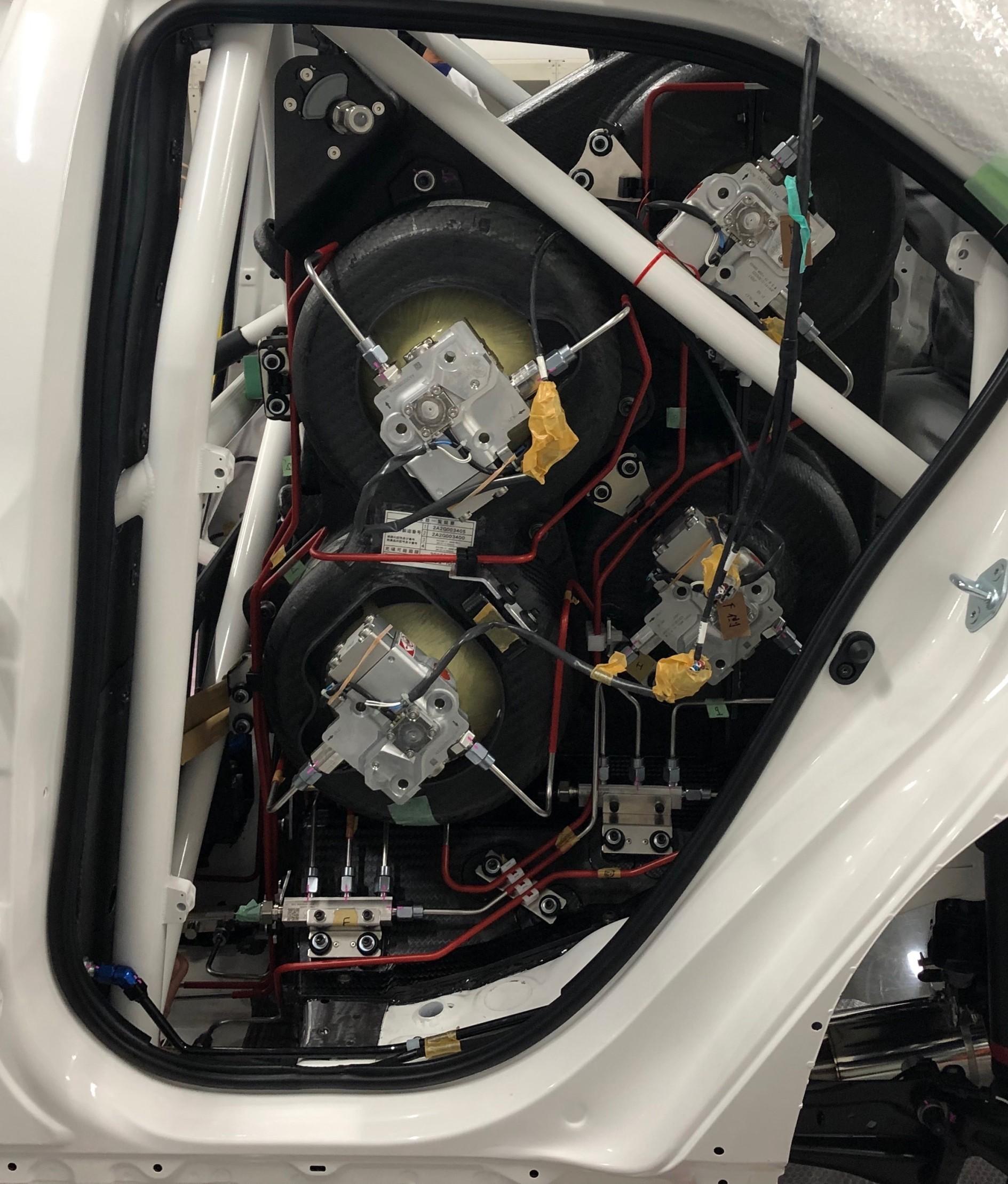

Looking at the actual race car reveals four tanks crammed into the space where the rear seats should be.

While the Mirai is equipped with three tanks of varying sizes (large, medium, small), the race car has a total of four – two of the Mirai’s medium-sized tanks, and two slightly shortened versions. In terms of capacity, the race car holds 180 liters compared to the Mirai’s 141. The car was packed with as many tanks as possible to maximize the driving distance on a single load of hydrogen fuel.

With the Mirai already on the market, its tanks have also cleared crash tests during development to ensure safety. That said, a race throws up vastly different conditions to city driving.

During a race, the car constantly runs at full throttle. As it turns out, this causes the temperature inside the hydrogen tank to steadily drop.

While cars developed for city driving are also tested under fairly rigorous conditions, a 24-hour endurance race is something else entirely. Even the engineers who had developed tanks for the Mirai and other fuel cell electric vehicles admit that the 24-hour race is ‘venturing into uncharted territory’.

To get the car race-ready, engineers also have to account for the possibility of high-speed collisions. Even if the car itself is not involved, it could be showered with fragments from a nearby impact. The car must be prepared for all such contingencies.

With this in mind, the team conducted a particular experiment during the development phase.

Known as a ‘penetration test’, it aimed to envision cases where sharp, high-speed projectiles could pierce the tank. As seen in the video below, a bullet-like object is fired at the tank at high speed to test whether safe conditions can be maintained.

Some other measures can be easily identified by looking at the vehicle. Carbon plates surround the four tanks in the area where they are housed, an example of the physical safety measures that have been put in place.

In part due to these carbon plates, however, the driver has zero visibility in the rear-view mirror. While this is common in full-fledged racing cars used by professional drivers, the upcoming race will feature non-professionals (known in the industry as ‘gentleman drivers’) such as Morizo.

According to the engineers, on race day the car will sport cameras, not installed during testing, that will allow drivers to check the rear via a monitor.

Technology honed through the GR Yaris can handle the heat

And finally, there is the story of the engine itself.

From the outset, the GR Yaris was a car built to win in motorsports.

Creating a production car first, then modifying it to compete in motorsports, was how Toyota used to do things. When Toyota rejoined the WRC, Akio himself acted to change this approach.

Begin by developing a car that can win in motorsports. Then turn it into a production vehicle that customers can drive. This is precisely how the GR Yaris was born.

Even after the GR Yaris went into production and sale, it continued to compete in endurance races and other events, constantly evolving through the cycle of break, fix, and repeat. This has become the way Toyota does things now.

The GR Yaris’s race-ready engine can handle high temperatures, high pressures, and high RPM.

The fact that this technology already existed lowered the hurdles when the team took up the challenge of building a hydrogen-powered engine.

This story gives the sense that Toyota’s various efforts, from competing in the WRC to building a hydrogen-powered engine, somehow all align in the same direction.

Shouldn’t a racing car be as light as possible?

Comparing the hydrogen-powered Corolla to other cars in the race, the obvious difference is the rear seat crammed with fuel tanks. The combined weight of these four tanks turns out to easily exceed 100kg. Lugging this burden around a racetrack puts the car at a clear disadvantage.

Normally, racing vehicles are designed to be as light as possible to improve speed and fuel efficiency. Peeking into a race car, ordinarily you will see nothing but bare steel plates, with all comforts removed.

This time is no different – all parts that can be omitted have been. In their place, however, are many unfamiliar gauges, which seem to symbolize the real goal of taking part in this race.

The racetrack provides a challenging environment unlike anything found on urban roads or regular test courses. There is no telling what troubles will assail this new technology, but the team will need to deal with them on the spot to carry on racing.

With the hydrogen-powered engine having finally arrived at the starting line, this 24-hour race will serve as a proving ground that will help to elevate the technology into something that will serve the whole world.

At the April 22 press briefing, GAZOO Racing Company President Koji Sato, who oversees this project, made the following remarks.

President Sato

And in motorsports, as you might guess, the (development) timeline is overwhelmingly fast and agile. Instead of making sure something doesn’t break, you push it until it’s broken, and then you truly know its limits.

That’s the kind of place for working on tomorrow’s technologies. Hydrogen presents many challenges, so making it something you own is not that easy.

To make such a technology a reality, you have to put yourself in a place where the time axis moves quickly, and you have to put things to the test again and again. It was as if I had been told: “If you don’t do that, the future won’t come any closer.”

The engineers’ vision

As the engineer in charge of the hydrogen-powered Corolla, at the final test meet Sakamoto expressed his gratitude to all of the team members involved.

Naoyuki Sakamoto

The fact that we were able to complete the car within a very short period (which would be impossible for a normal car) and start testing so quickly is a testament to all those who embraced the significance of the hydrogen-powered engine and worked hard to make this happen.

For me, while working on this project I have found myself thinking not only about building a hydrogen-powered vehicle, but about the future that it would bring about.

Testing this vehicle is about identifying potential future issues of this technology, and I believe it was our united vision that enabled us to get the car running without major trouble so far.

I believe that work brings happiness if everyone involved in the development can have a dream of the same future. I hope we can continue to work as one, with gratitude for the opportunity to be part of this project. Thank you for today.

Trouble is certain to arise during the 24-hour race. Despite that, the team will no doubt work to overcome those difficulties as they seek to last until the finish, to stay on the track for even a meter or a second longer, and to obtain more data for the future. They are not merely building a hydrogen engine, but also striving tirelessly towards the future it will create.

In the next part, Toyota Times will focus on the drivers’ impressions to find out what sort of car the hydrogen engine has created.