The commitment Akio Toyoda made after the tragic Tohoku earthquake, and how he sees the 9 years since thenーread about that and more in his remarks at the line-off ceremony for the all-new Yaris.

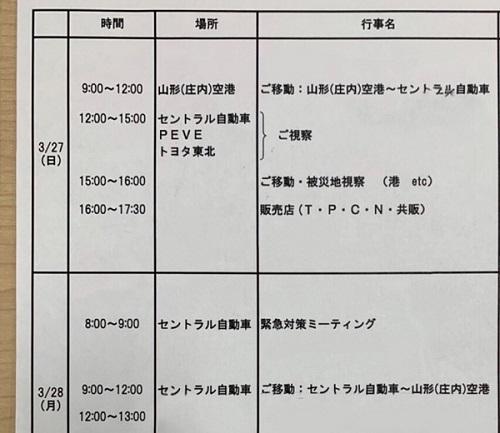

On March 27, Akio Toyoda, president of Toyota Motor Corporation, attended the line-off ceremony for the all-new Yaris at its production home, Iwate Plant of Toyota Motor East Japan. In his remarks, Akio reminded those gathered of the “continuous recovery support” that he committed to nine years ago upon seeing the disaster-stricken area, including how that support is continuing to be realized through developing the talents and abilities that cultivate people.

Nine years earlier, Akio visited one of the areas affected just two weeks after the Great East Japan Earthquake. As he saw the disaster area, he thought, “This area’s recovery will take a long time, and it behooves us to do something to support the area in a way that is not temporary but continuous and long-term.”

Based on that thinking, Toyota opted to make the Tohoku region its third production hub following its hubs in Chubu (where Toyota City is located) and Kyushu, by consolidating compact car production to the area.

What Akio insisted on was a recovery support program that is characteristic of Toyota, not one that is temporary or a one-time support. Believing that Toyota had more to offer, he committed to contribute to the region by helping to establish it as a long-term manufacturing hub, leading to the development of a new plant. To ensure its continuing development over the long-term, Toyota established an academy to teach manufacturing technical skills, which was the start of Toyota’s efforts to develop talent in that region.

As he toured the facility on this occasion, nine years on from the disaster, Akio could see and feel the pride the plant team members had and the level of recovery for Tohoku as they successfully launched the Yaris. Below are his comments that were given at the ceremony, encapsulating his thoughts and feelings on the momentous occasion.

As a quick reference, when looking at the numbers that show the level of change over the past nine years, Toyota’s shipment volume for Tohoku back in 2011 totaled in approximately 50 billion Japanese yen. Now, it’s 800 billion yen. Employment has also increased by 3,000 people.

Akio commented on these figures at an interview following the ceremony on March 27.

He said: “There are many suppliers and others who came with us after Toyota decided to make Tohoku another manufacturing hub. There are also those who previously were not doing automotive manufacturing but decided to join us in support of the automotive industry. I believe this is the result of the efforts made by all stakeholders.”

1. Yaris is my Aisha (beloved car)

Good morning, everyone. I’m Akio Toyoda from Toyota Motor Corporation.

Today, I’m honored to have Mr. Sagara, Director-General of Tohoku Bureau of Economy, Trade and Industry, Governor Tasso from Iwate Prefecture, Mayor Takahashi from the town of Kanegasaki, and many other stakeholders here at the line-off ceremony for the all-new Yaris. Thank you very much for joining us.

That being said, we were originally planning to invite many more to this launch event, and had hoped to ask them to be with us to see the Yaris start its journey to the world from here in Kanegasaki, Iwate.

Unfortunately, we were unable to do so under the current situation, but we plan to share today’s ceremony through Toyota Times at a later date.

Let me start by talking about my passion for Yaris, my Aisha—beloved car, and how I feel about producing Yaris in the Tohoku region.

I just said that Yaris is my beloved car. Some of you are probably thinking, “Doesn’t he usually travel in his Century?”, “The cars he actually likes are Supra or 86, right?”, or “He’s paying us a compliment, saying Yaris is his beloved car only because of today’s ceremony.”

In response to those thoughts, I would like you to take a look at this.

Akio then proceeded to share videos of his Yaris test drive and interview to the audience.

2. Iwate Plant – A plant that took on challenges with ideas of wisdom and ingenuity

I hope you can feel and believe how truly special Yaris is to me. If you look at my face when I’m driving one, I believe you understand how much I believe this car will be a success.

As I said in the video, in my opinion, the standard for making ever-better cars really is a compact car. While small and affordable, it should not leave customers the feeling that it is cheap. Rather, we want a compact car that gives owners a feeling of pride as they drive. A compact car is under pressure to achieve things that appear to contradict each other. This is why a compact car requires a manufacturer’s truest capabilities.

As you just saw, in addition to feeling good when turning, for example, the all-new Yaris gives drivers a premium feeling in its driving performance.

We improved its handling and ride comfort by increasing the welding spots as we make the body, which contributes to more rigidity of the body as drivers turn. Normally, increasing welding spots results in an increase to both production process and cost.

However, we knew that if the sales price could not be kept affordable, Yaris would not be a car of choice that would make customers happy. With that in mind, it was this Iwate Plant that took on the challenge by gathering ideas from those at the front lines, or genba.

They ended up making a new welding robot by themselves. The innovative machine shortens the work process by one-third. Being an in-house robot, if there is a defect, they can fix it by themselves. This further reduces wasted time. Team members here at the Iwate Plant have reduced waste, including wasted space and time, through their own ideas.

I cannot introduce all of those ideas now, but there are so many good ideas from the plant members everywhere here in this Iwate Plant. They have contributed to helping us achieve both “premium feel” and “affordable price”, the two subjects that usually run counter to each other. I would like to express my sincere appreciation to all of you at our Iwate Plant for achieving this. Thank you all!

3. Recovery support should not be based only on temporary measures

Today, it brings me immense happiness that we are launching Yaris and that I can be here in person to thank you personally in front of our plant members. I think this feeling comes because of the special feelings I have about monozukuri or car-making here in the Tohoku region.

It has been 10 years since I took the office as president of Toyota, but there are two days that I will never forget. One is February 24, 2010, when I attended the public hearing in the U.S. at the time of the recall crisis, and the other is March 11, 2011, when Japan severely suffered from being hit by the Great East Japan Earthquake.

At the time just after the earthquake, I remember heading to the affected area. It was moving to see the people of Tohoku making their utmost efforts in restoration and recovery, looking forward even though they themselves were also so heavily affected by the quake.

I recall making a strong commitment that “as a Japanese people, we should never forget this tragic earthquake.”

I realized that the recovery would take a long time, and I felt that we should do something together in a way that is not temporary, or a one-time support, but continuous and long-term.

At Toyota, we have long embraced a spirit of how we can "contribute to the development and welfare of the country" [wherever we do business]. In this case, we thought about how we can contribute to the Tohoku region, and the answer we reached was that we could contribute to the region through monozukuri.

4. Appreciation for the nine years of monozukuri progress in the region

Four months after the earthquake, in July 2011, Toyota announced that it would consolidate Kanto Auto Works, Central Motor Corporation, and Toyota Motor Tohoku Corporation. Then, one year later, we established Toyota Motor East Japan.

While there was a need to reorganize our manufacturing footprint due to shrinking new vehicle sales in Japan, in the background what I was most concerned with was how to make Tohoku the third manufacturing hub for Toyota following the Chubu (where Toyota City is located) and Kyushu areas, and how to make a production area for compact cars that are globally competitive.

Tohoku is a region that, despite its severe weather conditions such as its cold winters, has supported Japan for a long time with its rice farming through its hard work and ingenious ways to solve problems. Because of their unique abilities to handle challenges, I really hoped that we could help Tohoku recover from the earthquake by having the region make compact cars, the cars that really challenge our true capabilities in monozukuri, and, that by doing so, Tohoku could eventually lead Japan into the future.

After overcoming hardships in restoration and recovery, our Tohoku team members at Ohira Plant in Miyagi Prefecture and Iwate Plant now produce more than 400,000 compact car units annually for customers around the world.

However, the hardship they encountered was not only the recovery from the earthquake; there was also the integration process of the three companies that had different corporate cultures. Also, on a personal level, there had been a shutdown of plants in the Kanto area, and a relocation to Tohoku from there for many team members. After the hard efforts of all involved, we are now able to continue to make cars here. Also, many suppliers followed us and started manufacturing in Tohoku. I am certain that there were many hard times for them as well.

Again, I would like to express my deep appreciation to all of those who have been working so diligently to advance monozukuri here in Tohoku – Thank you!

5. Comments from one of the technical skills academy graduates

I have realized again this time that “monozukuri in Tohoku” is firmly connected to the future.

The Toyota East Japan Technical Skills Academy, an in-house training and education facility, opened its doors in 2013, and there have been 153 team members who have graduated from the academy and now work at the genba, or front lines.

One of the graduates who now works in the Iwate Plant said the following to me about the future:

“I believe that Toyota East Japan Technical Skills Academy will continue for a long time into the future. I’m a fourth generation graduate, so I’m still a young and early graduate. I believe that the kind of person I become going forward makes a strong impression on people’s perceptions about ‘how good academy graduates are’. Therefore, my goal is to be the type of person that makes future graduates want to say ‘he is such a respectful person because he is a graduate from the academy.’”

The young man is still in his 20s. His comment expressed confidence and a promising reassurance.

This reminded me of the “continuous recovery support” that I committed to nine years ago as I went to see the damaged area, and demonstrated one way it is being realized as we develop talents that cultivate people.

6. A bright future will come as people believe and move forward

“If there is no future for Tohoku, there is no future for Japan.”

I remember saying this at the end of my remarks at a ceremony held at the Miyagi Ohira Plant back in 2013.

In those days, I think we could only believe that we would see the future.

Nine years have now passed since the earthquake. Today, with the launch of the all-new Yaris at Iwate Plant, I can now definitively feel that the future of Tohoku--that we could only foresee vaguely before-- is becoming a reality.

I can now confidently state that I feel that there will yet be an even brighter future for Tohoku. I am really delighted to think about it.

However, we are now facing another time when the future is harder to foresee, but for a different reason.

Despite that, I firmly believe that “a bright future will come to us if we believe in it and move forward.”

Thank you everyone for helping me to think this way.

If there is no future for Tohoku, there is no future for Japan.

And without a future for Japan, there will also likely be no future for the world.

Let’s move forward together with a smile on our faces.

Thank you very much for joining me today!