Two engineers in charge of totally different vehicles, the Land Cruiser and GR Yaris, talk about each development approach to find their shared value and recent changes at Toyota.

Reforms implemented by Morizo aimed at making ever-better cars

The discussions held were unique despite the fact that both engineers work for Toyota. Sadayoshi Koyari, also known as “Mr. Land Cruiser,” has been in charge of developing the Land Cruiser for many years, while Naohiko Saito is the chief engineer in charge of developing the GR Yaris.

The former is an unrivaled cross-country vehicle, while the latter is a base model for a racing car, making the vehicles developed by the two men completely different. But as engineers, they both share the philosophy of “roads training cars,” “making ever-better cars” and “driving until it breaks.” These two engineers held candid talks on their attitudes toward making cars.

Serving as a moderator was Juichi Wakisaka, a TOYOTA GAZOO Racing ambassador, who has driven successive generations of the Land Cruiser.

“To begin with, what is your interpretation of reforms by Morizo (aka Akio Toyoda) aimed at making ever-better cars?”

Saito was the first to answer Wakisaka’s question.

Saito

I think what Morizo tried to do was to completely overturn our engineers’ attitudes. The level of evaluations that Morizo makes is in controlling a vehicle after pushing the wheels beyond their limit at speeds and Gs (during acceleration and cornering) that Toyota would never test its vehicles for.

When we got him to drive our GR Yaris first prototype, the development team was full of confidence. However, he began telling us that it was maybe impossible for Toyota to develop a sports car, or that we should perhaps leave it up to Subaru to develop a 4WD sports car. That’s how disappointed he was with our car. That’s how it all began.

Wakisaka, who has taken part in TOYOTA GAZOO Racing’s Nürburgring 24-hour endurance races on numerous occasions, points out that Morizo determined to implement genchi genbutsu on the front lines of racing after witnessing the practical development of production cars by European automobile manufacturers at Nürburgring from the early stages of development.

Saito

I totally agree. At Toyota, we have the TS (Toyota Standard = A quality standard that Toyota cars must meet), but until then, the high speeds and Gs encountered in the world of racing had been treated as exceptions. We used to regard such vehicles that undergo special modifications made by special people.

On the other hand, European manufacturers were using the same standards to not only develop sports cars, but also production cars.

For a long time, Toyota had an image of having conquered markets throughout the world with its passenger vehicles that were easy to drive and functional, yet affordable and durable, but Morizo’s reforms aimed to change the development to make Toyota cars even better.

Saito

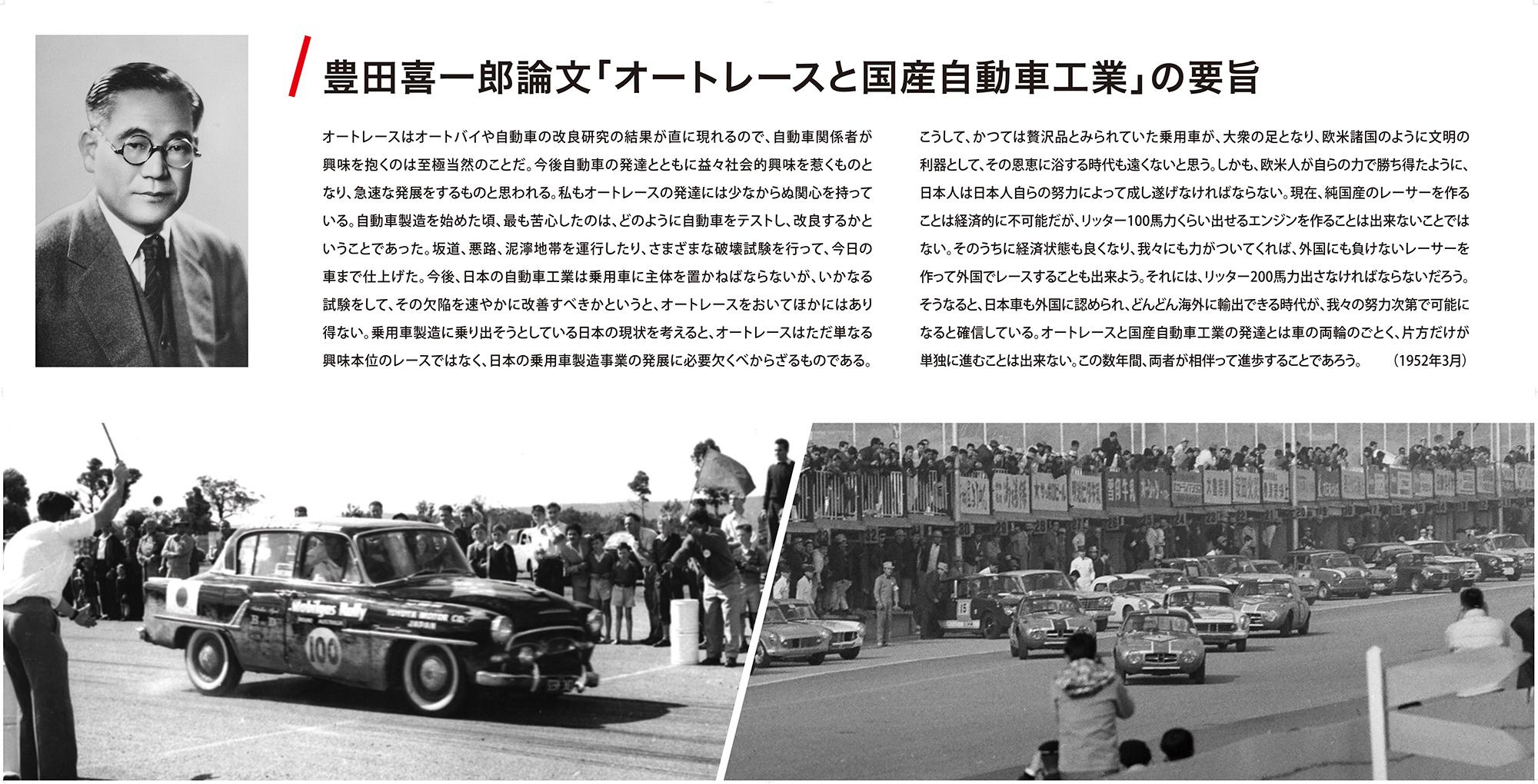

When you look back on the history of Toyota, the idea of making a production car from a racing car was already stated by Kiichiro Toyoda, the founder of the company, who said, ‘Auto racing is vital to the development of cars.’ This was exactly the kind of thing that motorsports and automobile development had to focus on.

The unique developmental environment leading to the originality of the Land Cruiser

Here, Koyari responded to the term, “passenger vehicle.”

Koyari

Toyota was a passenger vehicle company when I joined, but I was involved in making cars for commercial use. They’re fundamentally different from passenger cars in that you have to prioritize their reliability and durability. These are the two factors that are indispensable to customers in using their vehicles in daily life and for work.

Of course, in the Land Cruiser, we strived in pursuit of drivability on rough terrain right from the start. So, we cherished the idea of “not launching a product that we weren’t confident of,” which was also necessary in developing passenger vehicles.

These were the words of Hanji Umehara who developed the 1st-generation BJ model, and they’ve been passed down through successive generations of people in the Land Cruiser development team.

Our aim has been to ultimately convey our confidence to our customers and win their trust. I think it’s this belief that has been shared by generations of people involved in the development of the Land Cruiser.

When Koyari first joined the Land Cruiser development team, he said he was surprised by the developmental philosophy of the engineers and drivers that “Land Cruisers couldn’t be launched unless they had been driven until they broke,” but he eventually became engrossed in making cars through the Land Cruiser.

“At the root of Toyota’s car making is the idea of supporting people by enriching their daily lives and bringing smiles to their faces, but some of the environments in which Land Cruisers are used are very harsh, aren’t they?”

To the question from Wakisaka, Koyari responded as follows.

Koyari

Passenger vehicle users generally have good access to services in the environments in which they live, but Land Cruisers are driven every day in places where no one would come to rescue you if it breaks down.

Both the 40 Series and 70 Series are old models, but their reliability is growing by the year. It’s been 37 years since the 70 Series debuted, but they have constantly undergone kaizen (continuous improvement) during this time. So, their reliability is not something that was developed over just five, ten years.

To be honest with you, not all Land Cruiser owners are fully satisfied with their vehicles as they use the vehicles in demanding conditions. But in the end, they all say that they couldn’t find a better car. That’s why I must never become self-satisfied, or I can’t offer my customers safety and security. That’s why I have to stay on my toes all the time in developing the Land Cruiser.

The role of test drivers to engineers

Engineers are not the only people who guide the development of cars, but test drivers also play a vital role in doing so. Toyota has the Advanced Technical Skills Institute Division and test drivers known as “Takumi.” But what do the two engineers think of the role of drivers? Saito points out that racing drivers and test drivers play their own separate roles.

Saito

Both on-road and off-road, racing drivers are quick to find weaknesses in vehicles that are difficult to identify because they are compensated for by the performance of tires. They check the movements of the vehicle by working the accelerator in various ways after pushing it beyond its limit. That’s an ability unique to racing drivers, including their ability to push the vehicle “until it breaks” during races.

Meanwhile, our test drivers evaluate vehicles within the range of conditions that our customers use them in, including their upper limit. The cars are tested from both directions to the point where the conditions overlap.

When the range of speeds and Gs are plotted on a graph, you can see that the two types of data are completely separate from one another and the problems that surface are also different. But dealing with the problems identified by the racing driver also leads to improvements in areas that were found by the test driver to be problematic. The problems are inter-related.

For example, the racing driver may say there was a problem with understeering, while the test driver finds a problem with oversteering. But their steering speeds and braking forces at the time of entering a corner are different.

So, even though their opinions may be mutually opposing, you look at the data and you can see that there is oversteering under a certain range of conditions, and understeering under a separate range of conditions, allowing you to verify the consistency of the phenomenon. This then leads to the implementing of countermeasures in the suspensions or drive system or whatever.

That’s the kind of thing that we engineers were unaware of, and it’s the result of Morizo telling us to learn from the world of racing

By comparison, the Land Cruiser is based on the idea of in-house test drivers “driving it until it breaks,” while it continues its involvement in motorsports through the Dakar Rally. What is the role of drivers according to Koyari?

Koyari

In terms of the developmental philosophy of ‘roads training people,’ our Land Cruiser test drivers can’t fulfill their role unless they’re experts on roads. To test the vehicles, they must drive the cars off-road, and on roads used daily by customers throughout the world, to grasp a good understanding of the environments in which they are used.

Land Cruiser models are sold for a long time in one generation, extending the period of kaizen activities after their launch. On the other hand, the staff of development teams are transferred to other departments, so the passing on of knowhow on evaluating their drivability on rough terrain had been an important issue.

I had some concerns about fostering the human resources for this, but Takanobu Fukuoka (currently at Toyota Customizing & Development Co., Ltd.), who has been involved in the development of the Land Cruiser for over 37 years as a test driver, developed a certification system divided into three levels to try and standardize off-road driving skills.

They are currently fostering their second generation of drivers since this system began, but he says there is one more important thing he learned from the test drivers.

Koyari

In monozukuri, it’s important to have the ability to realize your own ideas, which is exactly what Fukuoka had.

For example, in developing the turn assist control, he manually made a vehicle with handbrakes that could be operated separately on the left and right, and verified its characteristics. It wouldn’t be an exaggeration to say that Fukuoka is responsible for proposing and testing the entire vehicle control system installed in our recent Prados and the latest 300 Series. He came up with ideas for functions that he wanted, then he would think about how he could turn them into mechanisms for realizing them. Fukuoka had the ability to give shape to rules and principles.

Test drivers come up with a lot of ideas on-site, and people who’ve been working on-site for a long time are good at improvising. We need people who have the ability to devote themselves to their ideas.

The skills of on-site craftspeople breathe life into development

It is not only the people involved in development, but also those involved in production, who are helped by the skills of staff members known as Takumi. Takumi are capable of giving shape to rules and principles.

Saito

In the past, we used to make a prototype first, then hold meetings with the people in charge of production engineering (PE) to prepare for production and begin manufacturing.

Of course, this required a long time, but in the case of the GR Yaris, we had PE engineers take part from the developmental stage. We looked at racing cars being made on-site, and worked together coming up with ideas on how to make racing cars that prioritized performance during the production processes at factories.

With normal racing cars, craftspeople take the parts of a completed vehicle and hone them one at a time before reassembling them. At GR Factory, they take bodies that differ subtly, and in the case of suspensions, for example, they choose parts that are compatible with the alignment precision from the start, and assemble them into the car.

Saito

Our production processes were prepared with PE engineers after seeing how racing teams involved in rallies and circuit racing made their cars in preparation for races. The challenge was to realize precision and weight savings equivalent to those of racing cars during the process of manufacturing production cars while keeping our investment level or costs. This would have been impossible to achieve if development had been carried out first with production processes being prepared after in the conventional way.

This was based on the idea of realizing the precision required of racing cars during production, made possible by the reforms implemented by Morizo. But Saito said it also had the effect of encouraging the involvement of people responsible for production.

Saito

If you ask something to be made in a particular way after completion of development, people will normally have difficulty understanding why. But with the GR Yaris, we were able to share Morizo’s vision for what he wanted to do in making a car right from the start, with the members of the production team.

We gave all the members in charge of assembly at the factory a chance to test drive the GR Yaris, and many of them actually drove the car. Before the cars come off the production line, each and every person involved in production is acutely aware of Morizo’s intentions. I think that’s what Morizo wanted to achieve in implementing his reforms with the aim of making ever-better cars.

On the other hand, how has the Land Cruiser development team engaged in their production, and what were the skills of Takumi that went into making them? Wakisaka asked Koyari this question.

Koyari

The Land Cruiser is renowned for its ladder frame, whose evolution is synonymous with the evolution of the Land Cruiser itself. But as a general rule, a ladder frame structure tends to make the car heavy, and there was a need to make the frame itself lighter and stronger.

On-site welders also came up with ideas for the lighter ladder frame deployed in the new 300 Series. Specifically, the steel material used in the frame was changed at key points and joined together like patchwork. Members of different thickness and rigidity were used at key points. They were welded together and bent by presses into integrated frames. So, there is no waste.

In the past, the plate thickness of the part that required the greatest durability was decided in advance, and the entire frame was made based on this thickness.

Technological innovation made possible thanks to the welding skills of Takumi has realized the lighter and stronger frame of the 300 Series. Land Cruisers are basically produced in Japan, and the frame is manufactured at Honsha Plant, which is evolving thanks to the production site at the factory.

Saito

Without the skills of people involved in production, we would not only be unable to assemble the actual cars, but both the GR Yaris and Land Cruiser wouldn’t even exist as vehicles.

Koyari

The bigger the company, the less they are inclined to try and downsize projects. But when you divide the labor too much, it makes it more difficult to share the vision of the development team with everyone involved. So, you run projects in compact teams, which strengthens the passion and will of members toward making cars. I think compact teams are also more conducive to implementing technological innovation.

Saito

That’s exactly how Morizo’s idea has been put into practice. The process of making cars has been downsized in a positive way.

As it was mentioned at the start of the article, the Land Cruiser and GR Yaris are completely different types of cars, but both development teams share the same philosophy and spirit. Part 2 will continue focusing on their car making.

Sadayoshi Koyari

Project General Manager, MS Product Planning, Mid-size Vehicle Company

Koyari joined Toyota Motor Corporation in 1985. As part of Engineering Division 1, he worked on chassis design for the Hilux and Land Cruiser Prado. From 1996, he was responsible for product development at Toyota Development Center 3; Since 2001, Koyari was involved in product development for the Land Cruiser and the new frame platform as Project General Manager. In 2007, he was appointed Chief Engineer at Toyota Development Center 1, and is currently in charge of the Land Cruiser 70 Series and the Land Cruiser Prado.

Naohiko Saito

Saito is in charge of development in the GR Project Operation Division at GAZOO Racing Company.

He joined Toyota Motor in 1997 after which he was placed in charge of solving technological issues in overseas service division. He was transferred to Toyota USA for three years starting in 2001, during which time he oversaw genchi genbutsu at various locations throughout North America.

In 2004, he worked as Chief Engineer in developing the new LS at Lexus Center. In 2009, he was placed in charge of developing aerodynamic technology at Higashi-Fuji Technical Center. In 2013, he was placed in charge of planning and developing the next-generation Yaris at TC Company. Since 2016, he has been in charge of developing the GR Yaris.