Toyota goes to the moon: What is Toyota's strategy for electrification? -

Interview between Naoto Ikeda (Motor Journalist) and Shigeki Terashi (Part Three)

An interview with Executive Vice President Terashi by motor journalist Naoto Ikeda was published on March 16th and 17th on “THE PAGE”, a news site operated by Yahoo’s subsidiary Wordleaf Corporation that highlights noteworthy trends and social problems in the world and explains them clearly. Based on the length of the content, TOYOTA TIMES serialized the content of this interview over five episodes with the cooperation of “THE PAGE” and Mr. Ikeda.

Toyota will embark on a project exploring the moon. Borrowing from the words of President Akio Toyoda, Executive Vice President Shigeki Terashi has stated that the challenge is to combine “the virtual with reality” and bring the technology on earth to the moon. In this, the forth episode of a five-part series, motor journalist Naoto Ikeda and Executive Vice President Shigeki Terashi discuss how Toyota is often criticized for being lead-footed when it comes to battery electric vehicles (BEVs), and how the top management of Toyota’s Technical Center thinks about and plans its future strategy to meet the global trend of vehicle electrification.

In the future, 30 years from now, the energy infrastructure will gradually change. In compliance with the Paris Agreement, Japan aims to reduce greenhouse gas emissions by 80 percent by 2050. How will Toyota face this challenge?

If society needs to reduce CO2 emissions to one-fifth of current levels, then, naturally, internal combustion engines cannot survive. Or rather, economic activity will have to be considerably reduced in society as a whole. Be that as it may, even if this effort was limited to vehicles, it would be a very important part of realizing a hydrogen society.

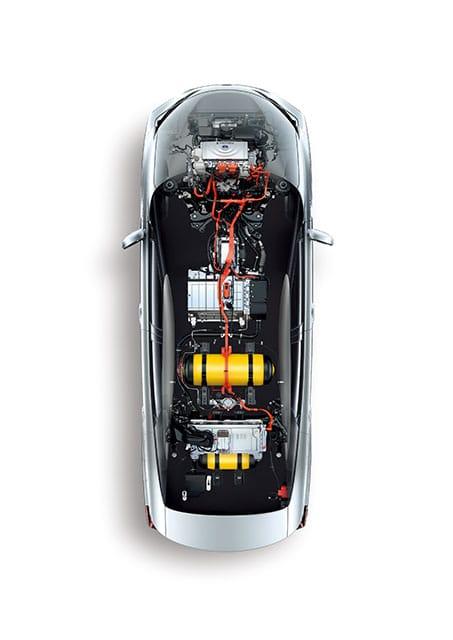

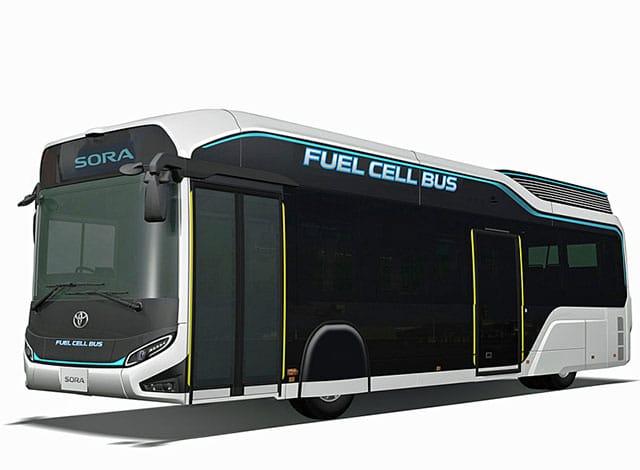

Currently, Toyota has only one type of FC (Fuel Cell) stack, which is installed in the Mirai. But the application range of FCEVs is expanding, such as for forklifts, which are suitable for indoor work because they do not emit exhaust gas, and the SORA, a large bus designed for public transportation equipped with two stacks. How will the FCEV evolve?

Toyota currently has only 11-12 percent of the world market share

- Ikeda

-

Up until now the current HEV (Hybrid Electric Vehicle) has been practical, but I heard that only PHEVs (Plug-In Hybrid Electric Vehicles) will be able to clear future regulatory standards. Then again, there is talk of BEVs (Battery Electric Vehicles) and FCEVs (Fuel Cell Electric Vehicles) joining the ranks of mainstream passenger cars. We will talk more about commercial vehicles later, but let’s talk a little bit about what we need to do right now to get to that point, and the unique benefits of the FCEV.

- Terashi

-

Up until now, we have talked about BEVs and FCEVs as if they were the same, but I actually think that in terms of the technological innovation of the FCEV, it would take an enormous amount of time to make an even more compact stack (the heart where the electricity is generated) at a low price. Therefore, I think that BEVs will lead the way and spread further faster, and FCEVs will follow accordingly. If the FCEV stack and tank can be made to be more compact, the BEV battery load will be reduced. That way, we will be able to switch BEVs to FCEVs.

- Ikeda

-

So, you mean that it’s not about conversion (retrofitting) from BEV to FCEV, but about being able to create FCEVs as a variation of the car model?

- Terashi

-

That’s right. We're currently working on the second generation FCEV that will come out next year or so, but we're simultaneously developing the third generation as well. As for the third generation FCEV tanks and stacks, we are saying that we will determine the size after carefully looking at the BEV packages of other companies.

- Ikeda

-

As you mentioned previously, that means as a system supplier.

- Terashi

-

Right. For example, if a company with BEV technology says “We want to sell FCEVs that align with the energy characteristics of this area,” then I think we would be able to reduce the amount of batteries to make them cheaper, load them with FC stacks and tanks, and make it possible to switch from BEV to FCEV while the motor stays as is. However, in order to do that, stacks and tanks would need to fit various-sized vehicles from a variety of companies.

- Ikeda

-

What is your target size for the stack when comparing it to the currently available stack?

- Terashi

-

I’m hoping that we can make it to be about 60 percent of the current stack's size. To load in small vehicles, big vehicles and vehicles somewhere in the middle, we only need to adjust the number of cells in the stack, just as you would adjust the number of batteries in a BEV.

- Ikeda

-

So, you hope to make a stack that is able to be combined based on vehicle size? A variable stack of sorts?

- Terashi

-

Basically. For example, in the case of trucks and buses, two stacks need to be loaded, and if you have an FC system that can accommodate different sizes, it will be possible to handle various case scenarios. For example, depending on the area, let’s say a town has a lot of hydrogen, and eventually plans to create a town with a hydrogen infrastructure. In that case, during the transition period in which FC systems are not cheap enough or compact enough, BEV trucks and buses can be used. When the time is right, since trucks and buses are easy to retrofit, FC stacks and tanks can be installed, and the motor can be diverted to accept the new source of energy, so FCEVs can be made immediately. Therefore, creating a “full coverage electrification coalition” doesn’t mean developing various systems individually. The fundamentals of the electrified portion of the base are the same.

- Ikeda

-

In other words, there are various areas and various needs, so it's about making solid fundamentals as a system to meet any need.

- Terashi

-

Yes, that’s right. So, for example, if we put a stack on a hybrid engine, and then put the tank somewhere, we can make an FCEV that is exactly the same as the hybrid configuration. Therefore, we need technology that makes the system compact, while allowing for cost reduction. It is all about making the system as affordable as possible.

- Ikeda

-

As it stands, tanks seem to be very expensive. What is the stack-to-price ratio?

- Terashi

-

Stacks are more expensive because they use platinum. We have to use technology that further reduces the use of catalysts and precious metals.

- Ikeda

-

Cost reduction is important to promote widespread use, and the use of rare materials does not allow for creating a large amount. How are you planning to solve this? What about the labor-intensive tanks?

- Terashi

-

Right now, we need to load a lot of a high-pressure tanks.

- Ikeda

-

Aren’t you using carbon now? And still working very hard to manufacture it, winding it by hand?

- Terashi

-

Yes, we use carbon. We make the tanks by winding carbon on a resin capsule.

We will have to think about liquid hydrogen in the near future

- Ikeda

-

Making them by hand takes a lot of time and effort, which is why the cost doesn’t come down. Also, I know that because it is large and the shape must be cylindrical to withstand high pressure, that has been a problem.

- Terashi

-

Right. That’s why we will have to think about liquid hydrogen in the near future. I think we will have to consider the hydrogen itself, including how it is placed, among a number of other things.

- Ikeda

-

I heard that Chiyoda Corporation said it is possible to mix it with toluene to make 1/500 the volume of gas at room temperature and pressure. And since it’s toluene, the gasoline infrastructure can be used as is. Both toluene and gasoline are legally classified as Hazardous Materials Class 4.1: Flammable Solids. That would make things very interesting, because then it would be possible to pump hydrogen just like pumping gas at a gas station today.

- Terashi

-

In addition to that, we need to develop hydrogen technology itself. In this case, if Toyota were to go it alone, it is already in the category of energy policy. The question is how to make and how to use hydrogen energy? This is no longer a matter that one company should work on and decide alone; rather, it is best left to teams made up of members from the public and private sectors.

- Ikeda

-

In short, the genre has become so broad, it is no longer reasonable for Toyota to handle everything.

- Terashi

-

It is exactly the same as the Lunar Rover. If you think about going into space and using a vehicle, I think every technology is an unknown question mark at this time. While I do think that Toyota has a role to play in sharing its vision with everyone, I don’t think Toyota needs to come up with all the solutions.

- Ikeda

-

Nowadays, when people talk about the environment, what often comes up is “Tank to Pipe,” meaning from the point where fuel is put in to where the exhaust gas comes out, and “Well to Wheel,” meaning from the point the oil is drilled to the spinning tires. There are many more ways of thinking, including beyond that scope, but for now, these two views are to some extent backed by the figures. FCEVs are definitely zero emission from the perspective of Tank to Pipe, but in terms of Well to Wheel, the situation changes depending on how the hydrogen is produced. If it comes from oil, that’s definitely not a zero-emission source. What are your thoughts on how to produce hydrogen at this time?

- Terashi

-

There is a debate about how to go from initially creating the energy to using it to run a vehicle, and I think it makes sense to have such a discussion. However, ultimately it comes down to what kind of energy plan a given region or country will go with in the near future. Therefore, taking a cross section to see how much CO2 is currently emitted in hydrogen production is certainly worthwhile, but we need to explore future changes in how to make hydrogen with less CO2.

Sometimes within Well to Wheel the order changes a bit, so even if the amount of CO2 emitted at an earlier stage is higher, it doesn’t mean it is untenable overall. If you look ahead to the landing point of the final energy plan, and think about what kind of technological development is needed to realize that, various options become visible.

There is no point in putting BEVs and FCEVs on opposite axes

- Ikeda

-

Therefore, if there are various electrification technologies, you are saying that the greater the corresponding range, the greater the degree of freedom in infrastructure energy design. For example, Toyota is now testing the “Hama Wing” in Yokohama and Kawasaki. The wind doesn’t blow only when it’s convenient. It may blow when it’s not needed. That being the case, the electricity generated is stored in a used Prius battery to produce hydrogen while keeping the power stable. That way, even when the wind blows at a time when power demand is low, such as at night, it can be stored as hydrogen. It is one way of storing energy by replacing it with hydrogen; just like storing electricity in a battery. Am I right?

- Terashi

-

Yes. Therefore, as I mentioned earlier, if you think of BEVs and FCEVs as being on opposing axes, it becomes a matter of which one is better or worse, but fundamentally, it is a matter of storing energy in battery or hydrogen form. Therefore, I think some energy storage options are better than others depending on how the energy is used at the tail end.

- Ikeda

-

You are absolutely right. And there is talk that commercial vehicles are probably the most suitable for hydrogen right now. In that case, unlike passenger cars, hydrogen stations would not be required everywhere one went, and all the more so for long-distance trucks, whose starts and stops are predetermined. Once the infrastructure is in place, there will be no problems. With such large vehicles, it is preferable for drivers to take shifts while the vehicle itself keeps going for 24 hours. It follows that a long charging time, as is the case with BEVs, would not be desirable. If a hydrogen refill took only five minutes, drivers could hop in and out and quickly be on their way. How is commercial vehicle development proceeding?

- Terashi

-

The original reason for making the Mirai FCEV was to meet the US ZEV regulations (see the additional explanation below). We started with the idea of building a passenger car. One future development, as you mentioned, will be commercial vehicles. Commercial vehicles don’t have users on a large scale. Rather, we usually get requests on the order of “Could you build us an FCEV garbage truck?” Quiet operation is an attractive feature if you often work late at night or early in the morning. Also, if you need to keep working for 24 hours, FCEVs are far better than diesel vehicles, whose loud noise disturbs the neighborhood during night road construction. That's why we have so many scale ideas and requests for using FCEVs.

If you make a passenger car like the Mirai and try to sell a lot of them, the conversation immediately turns to infrastructure maintenance, which is a very difficult subject. Thus, in the end we think that it’s best to have a combination of passenger and commercial vehicles. In the case of commercial vehicles, buses and taxies, the taxi business will continue to go well as long as there are a fair number of LPG (Liquefied Petroleum Gas) stands. I think things are easier with the vehicles that to some extent have a predetermined route.

If the travel distance is short and you don’t drive at night, BEVs should be fine, but as I said earlier, if you want to use the vehicle for 24 hours, FCEVs are the better choice. The same holds true for commercial vehicles. Rather than arguing about FCEVs vs. BEVs, I think it is a matter of which best serves the desired end. - Ikeda

-

That's why it's always possible to prepare a full line of products to be able to choose the one that best suits your needs.

- Terashi

-

Sure. Changing the subject slightly, what I am most interested in now is, of course, FCEVs and BEVs, but aside from that, have you noticed how many disasters have occurred in Japan lately, like the blackout in Hokkaido just the other day? When power outages occur, it's important to have a sense of security and to know that electricity and the lights will be available at night. The plug-in hybrid Prius (in Japan and Europe, Prius PHV, in the US, Prius Prime) is good for home use, but it can't provide ample electricity. If you think about the lighting and air conditioning needed for evacuees at an evacuation center, small vehicles would be useless, whereas something the size of a bus would serve very well. We have started launching a vehicle called the “SORA,” an FCEV motorcoach bus, but it would be a bit difficult for the average person to actually purchase one.

- Ikeda

-

Buses usually cost 100 million yen (roughly USD$1 million) and upwards.

- Terashi

-

It will eventually become cheaper, but it’s around that much right now.

- Ikeda

-

A standard bus costs about 20 million yen (roughly USD$200,000).

- Terashi

-

Let's say we make FCEVs or BEVs about the size of a Coaster microbus, even if subsidies were maintained forever, or even if everyone finds that these electrified vehicles could be deployed as countermeasures in a disaster, there would still be places where it would be painfully difficult to steadily increase the numbers. For example, let’s say a vehicle the size of an FCEV Coaster is normally used to carry customers or employees. When a disaster occurs, the vehicle could be rushed to where it was needed to supply needed power. Another example might be keeping a convenience store open (during a disaster) with an FCEV parked next to it. I think it would be nice to have an FCEV that is the size of a Coaster to prepare for when the need arises.

- Ikeda

-

In that case, it would most likely be necessary to design a grid to locate power source vehicles around the whole country. You would have to work closely with local governments and the country to make detailed designs.

- Terashi

-

That’s true. When we have talked about this with local governments, they have said that it is quite impossible to purchase a SORA FC bus, but they would buy one if it were more like a Coaster. Many companies say the same. Toyota dealers also say that they should own at least one, and we should all use them when trouble arises.

- Ikeda

-

Given such a positive trend, I see that the goal of Toyota’s electrification program is to be able to deliver the best solution for the region in order to contribute to society while considering environmental issues.

In the final installment of this long interview, Toyota claims the FCEV goes even further, with an ability to purify the air by extracting pollutants like the way an air purifier functions. We will hear about “minus emissions” in Toyota’s words next time.

Keywords; Zero-Emission Vehicle (ZEV) Regulations

Regulations on automobile exhaust gas originating in California, according to which makers whose volume exceeds a certain number of vehicles must sell a certain percentage of vehicles that meet the state's ZEV regulations. Failing to do so entails paying a large fine or buying a surplus (credit) from a maker who has met the requirements of the regulations.

Since 2018, ZEV regulations have become even more stringent, and the number of states that have adopted them has increased, causing this to become an urgent issue for North American-based makers.

The list below is the roadmap for regulations up to 2025*. The percentage indicates the total ratio of environmentally friendly vehicles to the total number of vehicles sold by the maker. In parentheses the values for ZEVs (Zero Emission Vehicles) are on the left, and the values for PHEVs (plug-in hybrids) are on the right. For example, in 2020, 9.5 percent of all cars sold must be fuel efficient vehicles. Ideally all should be ZEVs, but PHEVs can account for up to 3.5 percent. However, the amount exceeding 3.5 percent will not be counted.

2018 4.5%(2.0%・2.5%)

2019 7.0%(4.0%・3.0%)

2020 9.5%(6.0%・3.5%)

2021 12.0%(8.0%・4.0%)

2022 14.5%(10.0%・4.5%)

2023 17.0%(12.0%・5.0%)

2024 19.5%(14.0%・5.5%)

2025 22.0%(16.0%・6.0%)

*List current as of publishing date