Learning real monozukuri by making electric prostheses for others." There may be no better opportunity than [being a torchbearer] to spread the word about the project.

Introduction

To ToyotaTimes readers,

Originally, this series of articles was scheduled to kick-off coinciding with the start of the Tokyo 2020 Olympic Torch Relay, on March 26, 2020. The series is designed to introduce the Toyota employees selected to serve as torchbearers.

These torchbearers have expressed a desire to share that they are not running for themselves, but that they are running "for someone else."

Unfortunately, with the postponement of Tokyo 2020, the Tokyo 2020 Olympic Torch Relay has also been postponed.

For the Toyota torchbearers, however, while not able to run right now, there is no reason to delay highlighting their reasons for running. Therefore, this series will continue as scheduled, and it is hoped that readers will come to understand the desires and expectations the torchbearers have placed on their involvement in this once-in-a-lifetime opportunity to run.

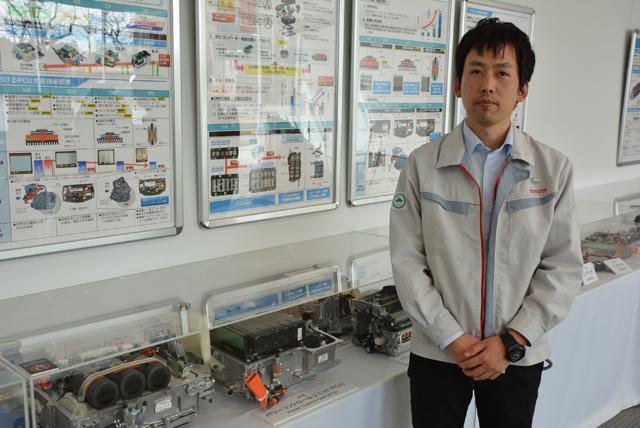

Yuki Jyojima,

Assistant Manager, Electricity Converter Advanced Development Dept.,

Powertrain Advanced Technology Div.

*Position at the time selected to be an Olympic torchbearer

Yuki Jyojima joined Toyota as career-track engineer in 2008. Initially, he was assigned to the department related to hybrid vehicle design. However, since then he has consistently been involved in the development of vehicle powertrain technology. Powertrain technology is the part of the car that helps it move, such as the engine or motor and related systems.

When asked about what initially motivated him to join Toyota, the first thing Jyojima mentioned was his “admiration for monozukuri (manufacturing).”

When asked to explain how he is currently involved in monozukuri at Toyota, he replied:

“In powertrain development, although we make some parts by ourselves, we still need to procure various parts that are only made by certain suppliers. Normally, we will request a supplier to develop parts based on a design we have created. Then, when we receive the parts, we will check to see if they meet our requirements and function properly when installed in the vehicle.

From a manufacturing perspective, various parts have been developed collaboratively with our suppliers in order to promote monozukuri. As an engineer, I need to acquire the skills that will allow me to keep up with them, as there is a tendency to rely on them for detailed technology.

At the same time, in addition to being concerned about the design of the ‘parts’ that comprise the powertrain, we have to think about the whole ‘product,’—the car—as we want to value the viewpoint of ‘how it will be used by the customer.’”

Learning real monozukuri by making an electric prosthesis

Jyojima speaks with the detached confidence of a professional as an engineer. However, as it is someone else making the parts, he said the situation made him feel “in a hurry to manufacture something” himself.

Based on this line of thinking, Jyojima decided to take action, eventually settling upon something he had never come in contact with before, a project working on an electric prosthesis.

“At first, I just wanted to make something, it didn’t necessarily have to be an electric prosthesis. While researching various project ideas, I stumbled upon a start-up company that had released plans on how to make an electric prosthesis. So, I started to make one while looking at the manual on their website.

However, upon completion, I didn’t feel a sense of satisfaction. Rather I felt an emptiness. The project, a prosthetic hand, was created based on the premise that someone would actually use it. When I took a step back and looked at what I had made, I thought, nobody will use it and I hadn’t had someone specific in mind when I took on the project. When I thought those things, the emptiness I felt was unbearable. So I thought to myself that I should meet people who would actually use a device like this.

The problem was that I didn’t have an intermediary or means of contacting such people. It was too intimidating to suddenly ask a person who I might think needs it unexpectedly by suddenly asking them uninvited questions like ‘What kind of impairment do you have?’ and ‘How do you feel about it?’ So I contacted a representative of the start-up company I had pulled the designs from to seek advice. They introduced me to a non-profit organization (NPO) they were involved with. The representative at the NPO said, ‘Why don’t you come along to the next gathering? You can meet all kinds of people.’ So I took them up on the offer to join as an invited guest.

One man I met at the second or third such gathering had lost four of his fingers of one of his hands in an accident. Most prosthetic hands completely encase the wrist. The man I met seemed to have given up on getting one for himself, and said something to the effect of, ‘I want a prosthetic hand, but there is nothing that is suitable for me…’ Though normally cheerful and bright in his disposition, upon mentioning his desire for a prosthetic hand, however, he became a little despondent. Seeing his face, I honestly thought to myself, ‘Can’t I make something for this individual?’, and I asked him ‘Will you allow me to try to make a prosthesis for you?’”

Since meeting that man, Jyojima would embark on a “real monozukuri project for someone else.” Working together with the man, it took about one year for Jyojima to complete his work. While referring to publicly available information related to electric prostheses and getting advice and support from the information publisher, he was finally able to deliver a finished product in December 2019.

“I made the initial prototype in about four months. The remaining eight months were spent fitting it to the hand of the man who would be using it and adjusting it so that it would be easy for him to use. It made me realize again the difficulty associated with customizing something for a particular person.

The man wears the hand in his daily life and has sometimes filmed videos of himself using the prosthetic hand to grab various things. Of course it was very encouraging to see his videos. One video that made me particularly happy included a scene that he shot of himself playing cards with his daughter while wearing the hand. When I saw him doing something he couldn’t do before and having so much fun with his daughter, I thought ‘I’m so glad I did this’ from the bottom of my heart.

Working to expanding the prosthetic hand manufacturing base

An initiative that was started with an “impatience to be involved in monozukuri” resulted in the creation of a product that was able to please someone. This outcome may have been the catalyst that provided Jyojima with a new state of mind. Then, an opportunity to be an Olympic torchbearer presented itself to Jyojima with timing almost as if he had planned it.

“While working on the prosthetic hand, I showed it to my supervisor and told him that it ‘is a project I am undertaking on my own.’ He advised that ‘rather than doing it all alone, it would probably be better to have more people come to know about it.’ And then, he said, grinning, “Oh, by the way, I have put in a recommendation for you to be an Olympic torchbearer.’

[When the torchbearer opportunity had been introduced to all of us], I felt it was kind of delicate and required a degree of sensitivity, so I had not even considered raising my own hand to be one. Even after the selection process started for those of us who had been recommended, I tried to be considerate of other people’s needs and asked the man for whom I had been working on the prosthetic hand his opinion about making the project more widely known. After being selected as one of the torchbearers, word of my prosthetic hand project seems to have spread among my colleagues at work and others around me. Now, I feel very grateful about being selected, as there may be no better opportunity than this to spread word about the project.

Prosthetic hands are different from commodities like PCs and mobile phones that almost everyone can use in the same way. Prostheses need to be customized to the shape of each person’s hand and adjusted for the degree of their impairment. I became keenly aware that it would be impossible to provide such a product to a lot of people just working on my own.

To solve this problem, I thought it would be good if people who had impairments and those who supported them had access to some kind of scheme that would allow them to independently make a prosthetic hand. So I have put together a manual for the type of prosthesis I have created this time, and am preparing to release it when I participate in the torch relay. Hopefully, this will serve to help establish such a scheme to help society.

This is because, of course, people who need this help are not limited to those found in Japan. Once the Japanese version of the manual has been completed, the plan is to create an English one, as I want to be able to respond to requests for help from overseas as well. By opening up and distributing this information, my hope is that we can, even if just a little, interest as many engineers as possible and consequentially expand prosthetic hand manufacturing activities.”

Upon nearing the end of the interview, Jyojima, smiling self-consciously, said, “I know I was a large burden on my wife while concentrating on making the prosthetic hand.” As he said this, he nodded, confirming his thoughts of gratitude to his family who supported him the most. Then, his countenance shifted back to his engineer's face once again.